Help with choosing supports.

Here is the file if you would like to look at it.

Scrap Mechanic Lift By Armality

Hello there, apologies in advance I am very new to 3D printing.

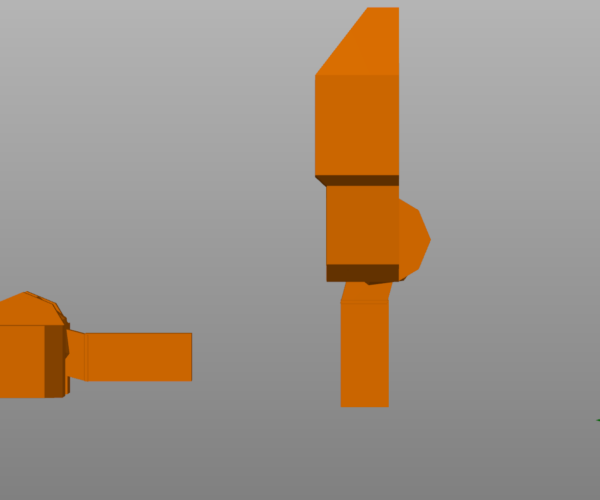

I am having troubling figuring out which way to do my supports. The piece is X:37mm Y:22mm Z:7mm (first picture left piece)

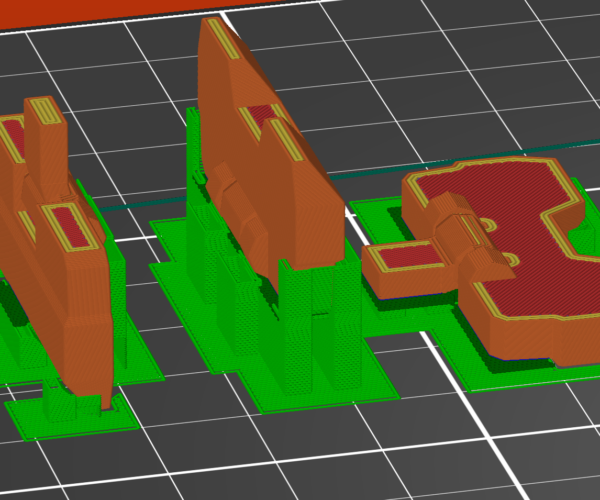

I have tried printing this once before and the supports welded to the piece. They would have needed to be sanded to be removed.

Any input would be appreciated, thank you.

This part is not well suited to 3D printing but it should be possible.

First: is that supposed to be a rotating hinge? If so then it is not modelled with enough clearance/tolerance and will sieze.

Also if so: it would print best if the hinge were rotated so the pin stayed flat but the body of the part, at 90 degrees, stood on its hinge end.

If not a hinge:

Why is the cuboid Support Leg Pin printed so close? it simplifies the print if moved aside, then the part could again be printed on that face with less support than other orientations.

In Print Settings > Support material try changing the Top contact Z distance I suggest 0.2mm as a first try.

Cheerio,

RE: Help with choosing supports.

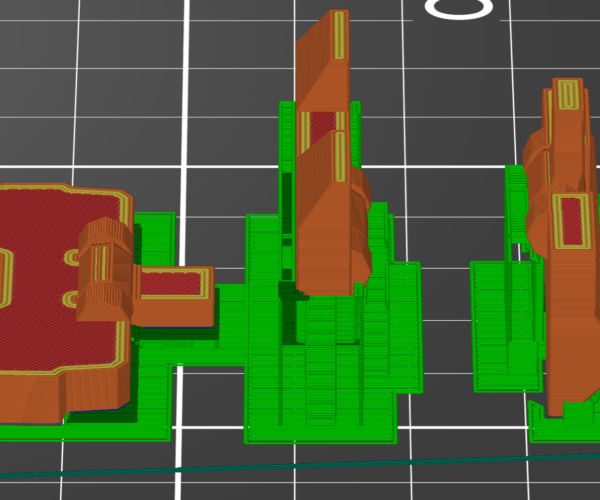

I am assuming, you have shown us the same model 3 times in 3 different orientations?

If there were no further considerations, I would choose the right-most option, where it stands upright, as that would leave the supported areas on the side, giving a better surface finish on the top and bottom.

If your support welds to the print, it is too close to the model. Under "support material", there is "Top contact z distance". On a tuned printer 0.1 should work fine, but you might go with 0.2. In addition, take a look at "XY separation between an object and its support". Most of the welding I have experienced came from the XY separation being too small and not the top z distance. I use 160% XY separation and Top contact z distance of 0.1 for supports, that can be broken off by hand.

Prusa Mini FW4.4.1

RE: Help with choosing supports.

And please, please, switch to Snug support style.

RE: Help with choosing supports.

This part is not well suited to 3D printing but it should be possible.

First: is that supposed to be a rotating hinge? If so then it is not modelled with enough clearance/tolerance and will sieze.

Also if so: it would print best if the hinge were rotated so the pin stayed flat but the body of the part, at 90 degrees, stood on its hinge end.

If not a hinge:

Why is the cuboid Support Leg Pin printed so close? it simplifies the print if moved aside, then the part could again be printed on that face with less support than other orientations.

In Print Settings > Support material try changing the Top contact Z distance I suggest 0.2mm as a first try.

Cheerio,

Thank you for the reply.

It is a hinge in the video game but I am not planning on printing it like one. The plan was to have the cuboid piece slot into the support leg pin hole on the "top 2" piece. With the part being so close will it not print as if it were one whole piece?

RE: Help with choosing supports.

I am assuming, you have shown us the same model 3 times in 3 different orientations?

If there were no further considerations, I would choose the right-most option, where it stands upright, as that would leave the supported areas on the side, giving a better surface finish on the top and bottom.

If your support welds to the print, it is too close to the model. Under "support material", there is "Top contact z distance". On a tuned printer 0.1 should work fine, but you might go with 0.2. In addition, take a look at "XY separation between an object and its support". Most of the welding I have experienced came from the XY separation being too small and not the top z distance. I use 160% XY separation and Top contact z distance of 0.1 for supports, that can be broken off by hand.

Thank you for the reply.

Yes, it is the same part in 3 different orientations.

I will give those setting a try, thank you.

RE: Help with choosing supports.

In my opinion it is best to keep the original position,

and select the option 'support only from the bed' in Prusa slicer.

And please, please, switch to Snug support style.

Thank you for the reply.

I will give switch the support style and use the settings suggested by others and do a print of just one of the pieces.