Nozzle 0.6 and retraction

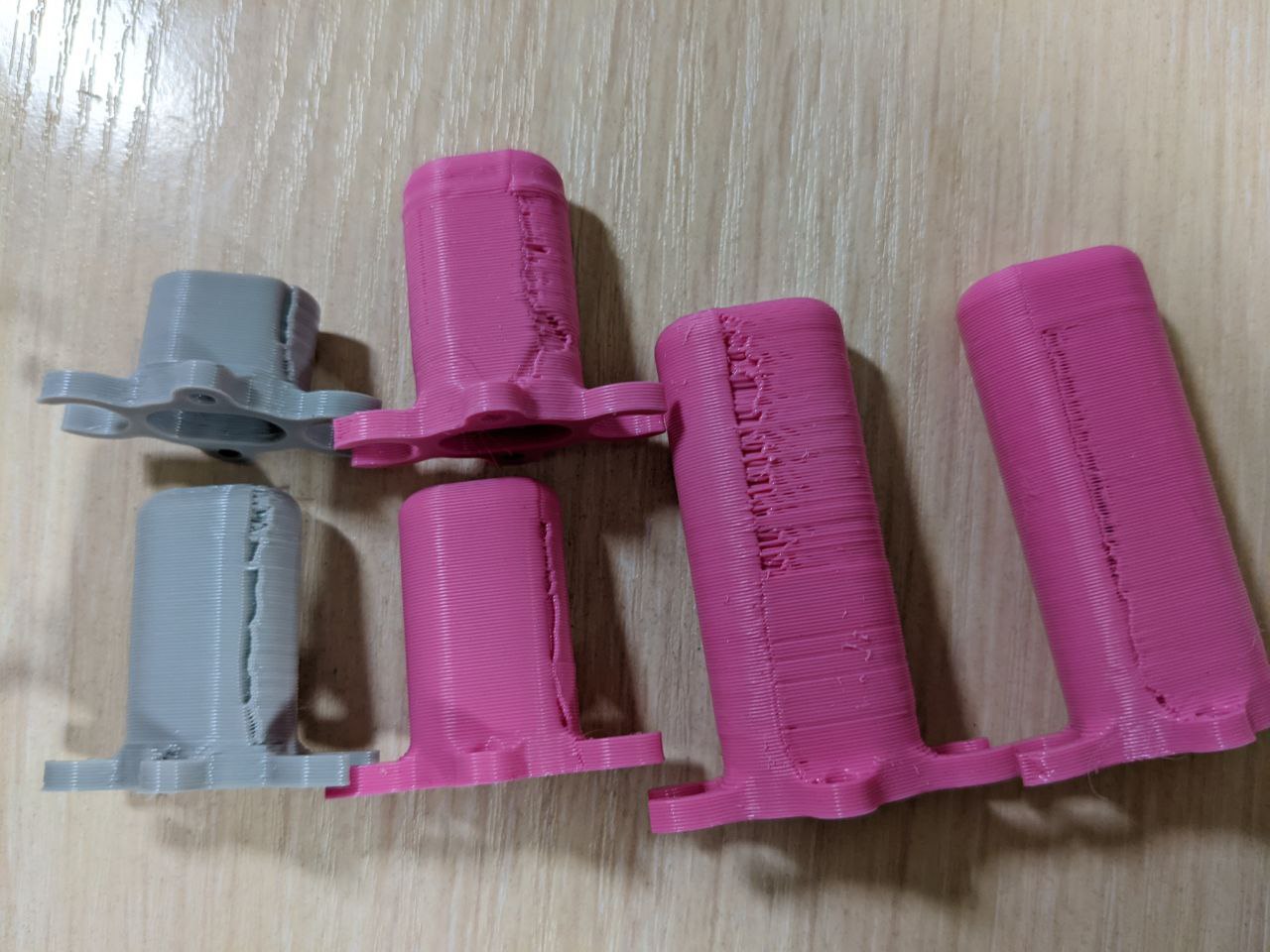

I'm printing bunch of items. Result is totally ok with nozzle 0.4, but I can't make it work with 0.6.

Params: nozzle 0.6, PLA, layer 0.3-0.35, fill 50% gyroid, 1 wall in perimeter

Nozzle is quite cheap, but new. It should not cause such a problems.

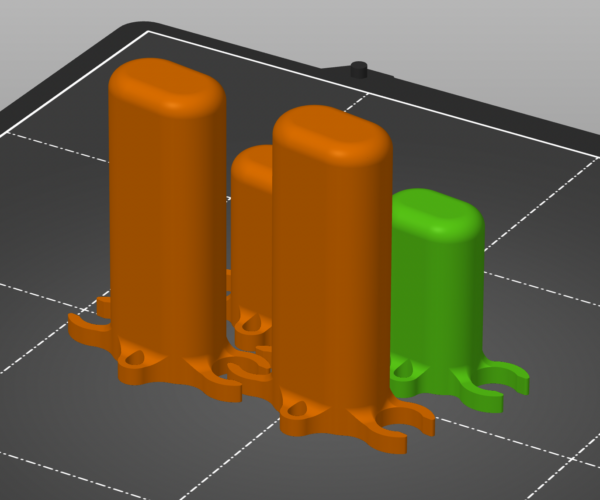

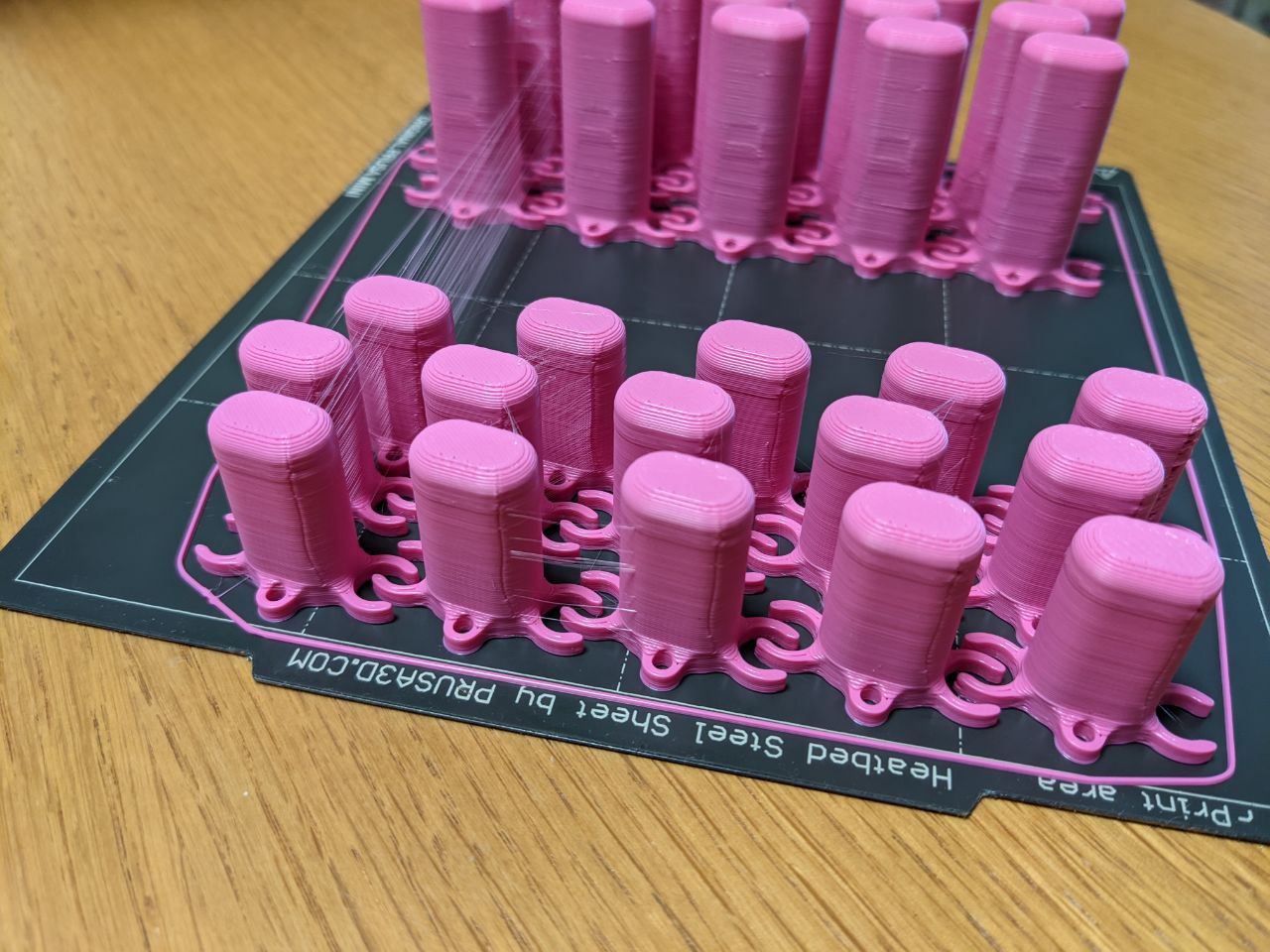

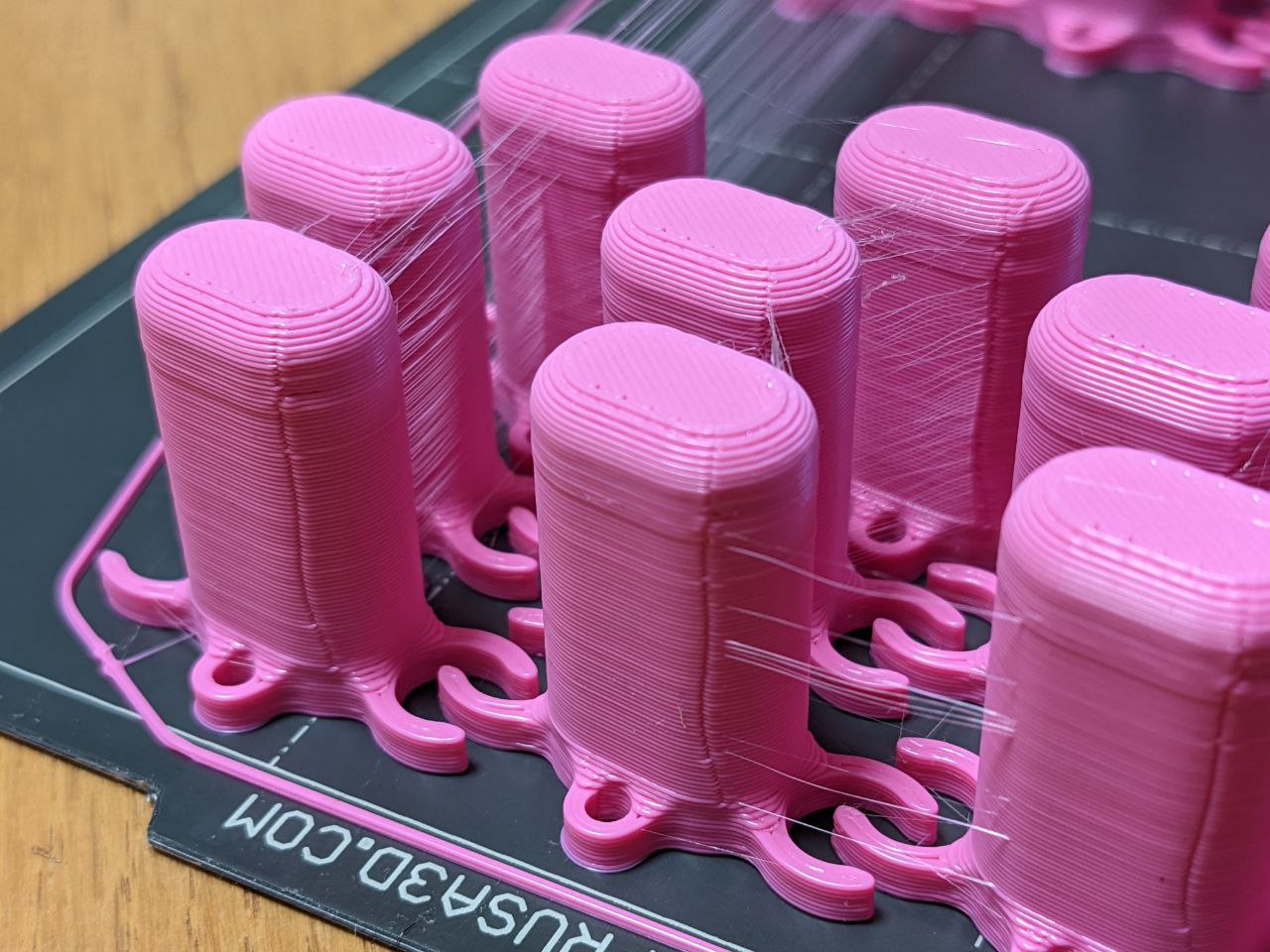

Problem 1: Strings. I can't avoid it. Retraction length up to 5mm, retraction/deretraction speed up to 140, wipe on/of, temp 190-230 - result may vary, but anyway oozing is present(not all travel path between items have it):

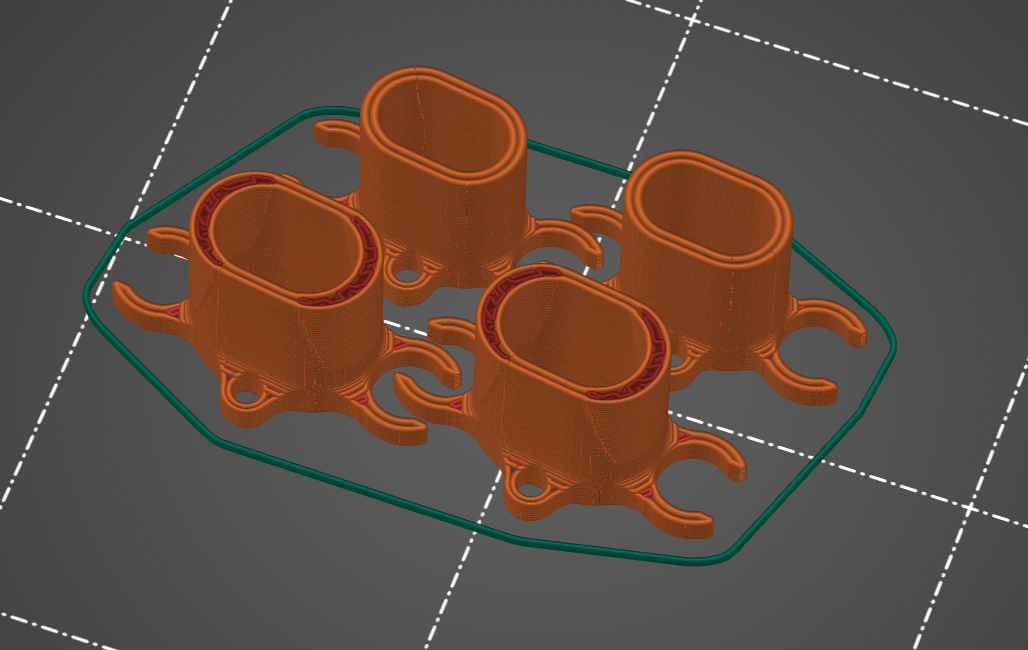

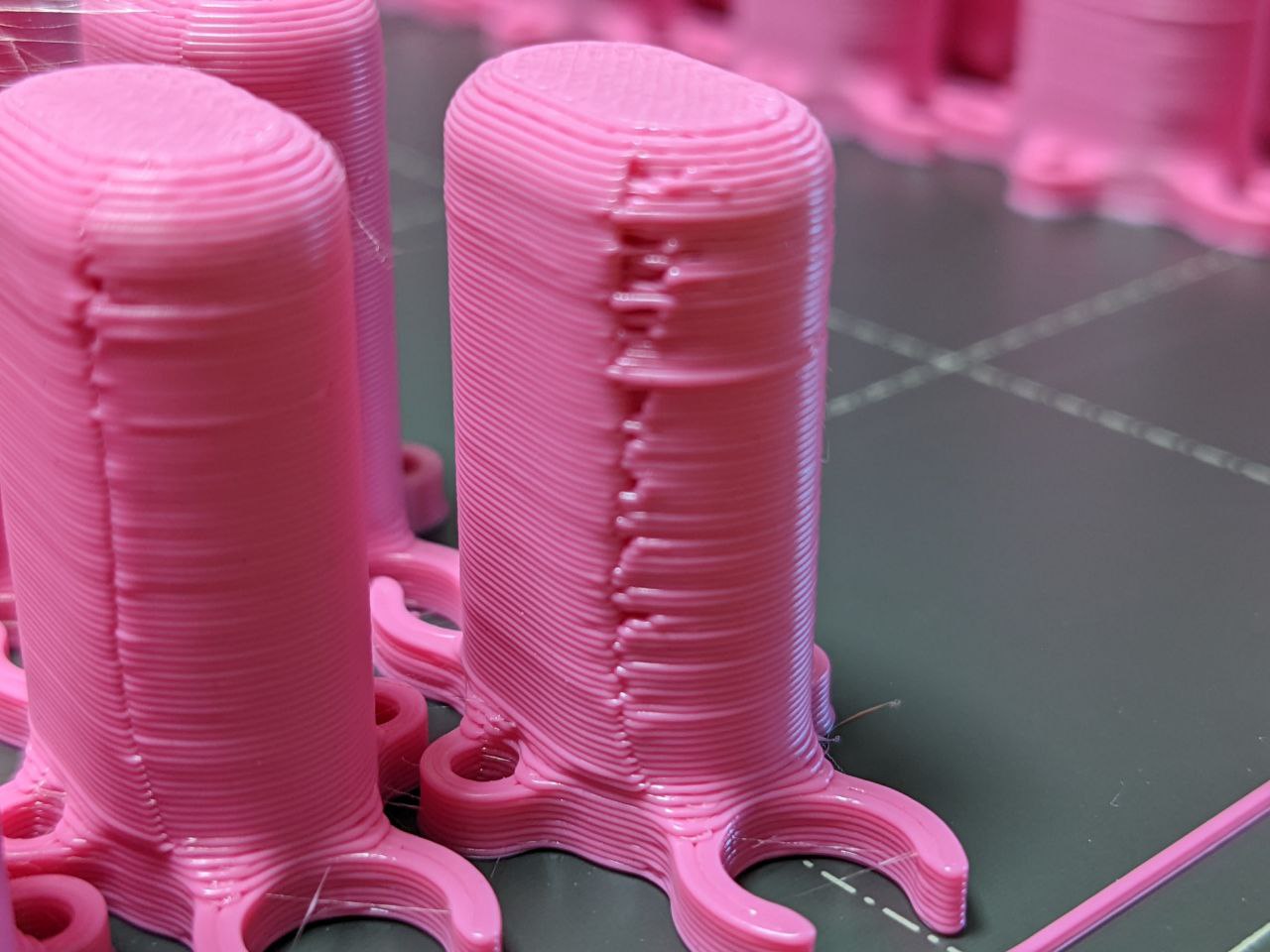

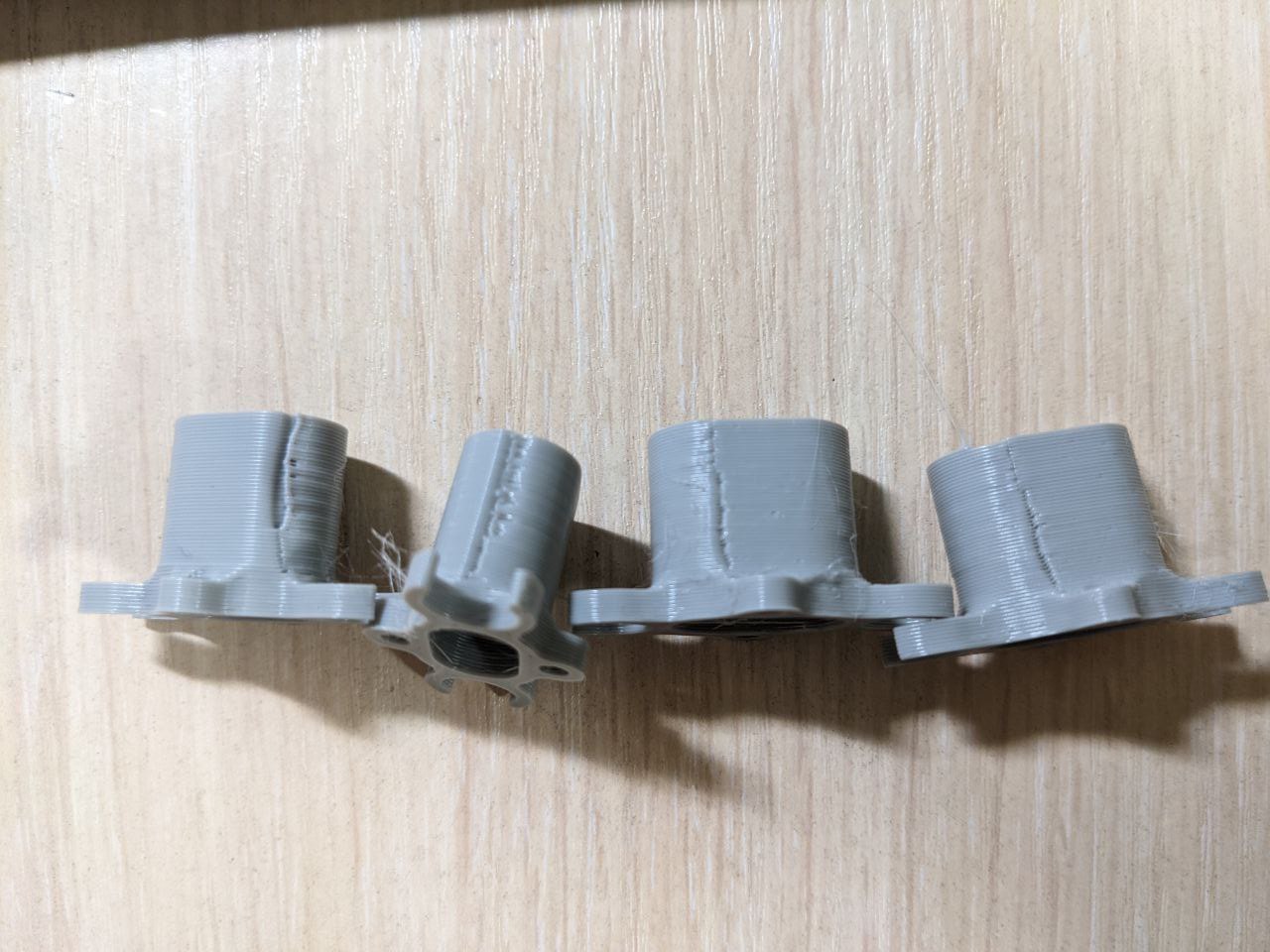

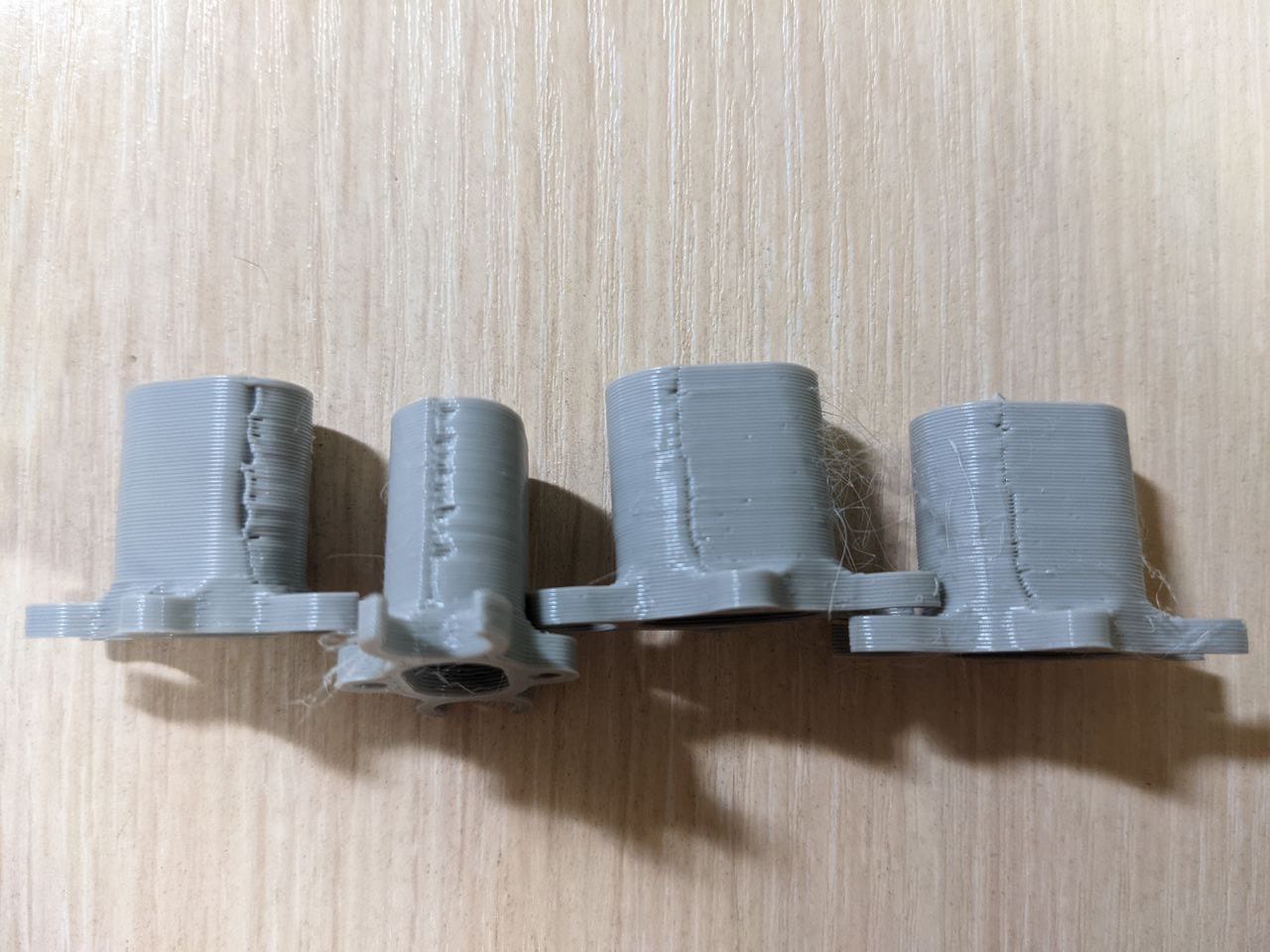

Problem 2: Seams. When build volume is fully loaded some of items are totally ok(pic1), some are almost ok(pic2), other - totally bad:

All this ok/semi-ok/bad variants could be present at same set of items:

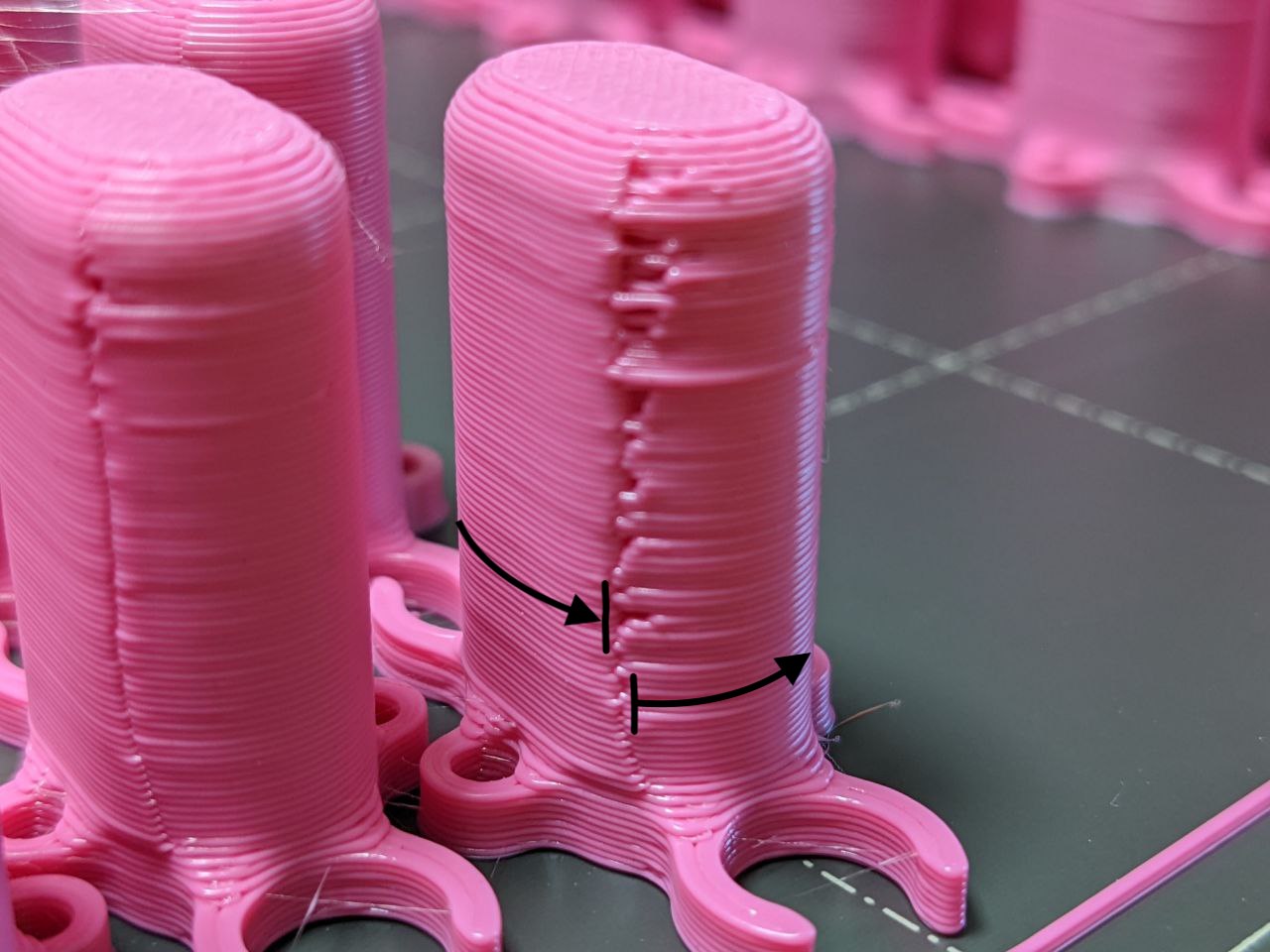

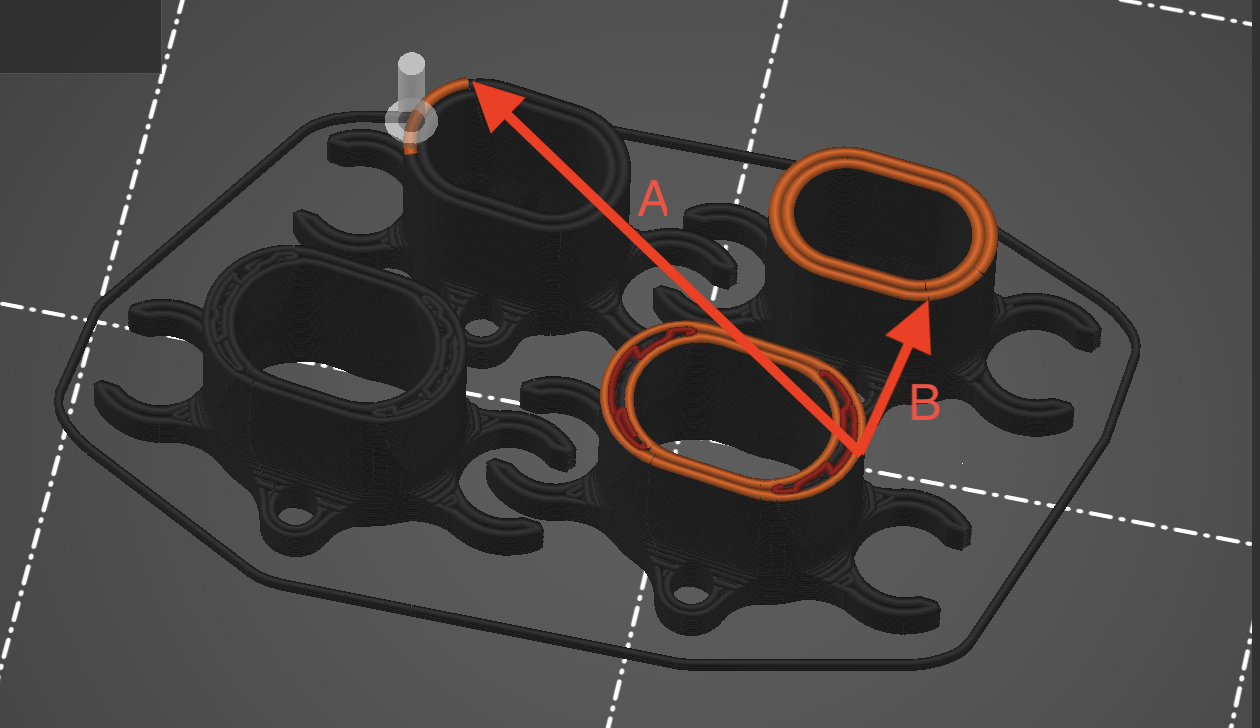

Found out experimentally that this bad part is a start of path after traveling. And it depends on traveling length: with a long journey(path A), the result will be worse than with a short one(path B):

It looks like there is a dependency between deretraction and this problem. By default retraction speed is bigger than deretraction(70 vs 40). If I make it even(70 vs 70) the result become slightly better(but no visible difference, if deretraction is higher - 70 vs 140).

The only conclusion I can draw is that somehow the printer can't return the filament in time after the travel. And as bigger travel is, the longer it takes the printer to start extruding well. Played around with a spring compression in clamping mechanism - no effect.

And now I have a dilemma: because of Problem 1 I have to increase retraction but Problem 2 become worse, or vice versa.

There is something that I definitely missed here, but I'm out of ideas. Any thoughts?

RE: Nozzle 0.6 and retraction

have you tried going back to standard retraction and reducing temperature on nozzle?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Nozzle 0.6 and retraction

I don't have a mini but does I believe it supports Linear Advance. Id be looking to tune the LA value for that filament/nozzle combination (usually stored in the filament profile settings custom gcode section) before playing around with retraction etc too much.

RE: Nozzle 0.6 and retraction

have you tried going back to standard retraction and reducing temperature on nozzle?

regards Joan

Yes. With default retraction:

Noname PLA(200-220C). Temp 210(pic1), temp 200(pic2).

Prusament PLA(205-220C). Temp 210(pic3), temp 200(pic4).

RE: Nozzle 0.6 and retraction

sorry, I don't have a 0.6mm nozzle on my prusa's at the moment,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Nozzle 0.6 and retraction

You might want to tweak Pressure equilizer under Print Settings -> Speed -> Pressure equilizer . This changes feed rates on start and ending of a layer.

An increas in retraction will also increase the risk of holes a start of layers since that might pull the filament to far back. Lowering retraction to 2mm will make a few of the holes go away.

Have you dried your filament? Humid filament can be a cause for strings. Strings can easily be solved during post processing. I would focus on the gaps in the prints first.

Printer: Original Prusa Mini+

Nozzles: E3D 0.25, E3D Nozzle X 0.4 , E3D 0.4, Bondtech 0.6 CHL

Printables: Tysonsw

Mastodon: [email protected]

.

RE: Nozzle 0.6 and retraction

Ok, next round of tests. It could be reproduced with 0.4 nozzle also.

For now I've tried it on:

- another Mini+(0.4)

- my Mini+(0.4)

- Mini+(brass/steel 0.6)

- Mini+(steel 0.6) with another filament motor

In worse case it looks like this (0.4 nozzle):

Id be looking to tune the LA value for that filament/nozzle combination

You might want to tweak Pressure equilizer under Print Settings -> Speed -> Pressure equilizer

Tried LA and Pressure equalizer(separately and in different combinations) with both 0.4/0.6 nozzles. No visible effect.

Have you dried your filament?

I've used 4-5 different brands(including Prusament), just opened, PLA only. Didn't dry it additionally.

Here is the test stl. In my case it's enough to place 2 of it on a table. Standard settings

I didn't try, but I suspect it could be reproducible with any object. Make simple cylinders(or maybe Benchy?) and place it far from each other(in opposite corners).

RE: Nozzle 0.6 and retraction

Stringing may be a function of the larger nozzle, I can't say for sure, I've never used a 0.6.

Have you tested your feed rate is correct for 0.6? I know we'd all assume that picking a 0.6 nozzle in Prusa Slic3r would calculate the correct rate, but maybe it isn't enough?

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Nozzle 0.6 and retraction

things that you might want to try :

1. revert back all your settings to default and replace your PTFE tube inside your heatbreak and test print again. if this method doesn't work,

2. after you revert all settings and replace PTFE tube, try to reduce retraction length to 2.0mm, it should works for prusa mini, i've tried 1 mm retraction and still works with prusa mini.

i hope this will help you.

RE: Nozzle 0.6 and retraction

I've used 4-5 different brands(including Prusament), just opened, PLA only. Didn't dry it additionally.

New filament does not equal dry filament.

Printer: Original Prusa Mini+

Nozzles: E3D 0.25, E3D Nozzle X 0.4 , E3D 0.4, Bondtech 0.6 CHL

Printables: Tysonsw

Mastodon: [email protected]

.

RE: Nozzle 0.6 and retraction

Same problem here. I think it's related to oozing. When the traveling path is longer, there is a bit more oozing (or stringing if you like to call it as its just a tiny amount) which causes insufficient filament in the nozzle after de-retraction to directly push it out and continue the print. This is more obvious with 0.6mm nozzle than with 0.4mm but in both cases its there. In my opinion there should be an option added to the slicer to set "deretraction extra length" depending on travel path length after last retraction.

RE: Nozzle 0.6 and retraction

If anyone interested then they should really read this https://github.com/prusa3d/Prusa-Firmware-Buddy/issues/2997

See my GitHub and printables.com for some 3d stuff that you may like.

RE:

I have a MK4 and not a mini, but I also have a Voron 2.4. On the Voron with a 0.6 nozzle, I had a very similar problem until I changed the pressure advance settings. The MK4 has these settings in the filament start Geode. I will admit, getting a proper value has been a real challenge for me on the Prusa because the slicer makes it more difficult to print a test print that can easy to track pressure advance settings.

I've seen these effects in other posts but haven't figured out how to correct them. The pics show before and after pressure advance settings were changed. Again these were on my Voron. I haven't been as successful on the Prusa.

RE: Nozzle 0.6 and retraction

Pressure advance adjustment for the Mini is discussed here:

Adjusting the extruder tension, flow multiplier and the pressure advance setting was helpful even with the stock nozzle.

Extra deretraction would make the seams better but result in a fuzzy mess otherwise. That thread has some pictures.

Regards,

Mark