Failed Prints on Prusa Mini+ . Potential Under Extrusion?

Hi All,

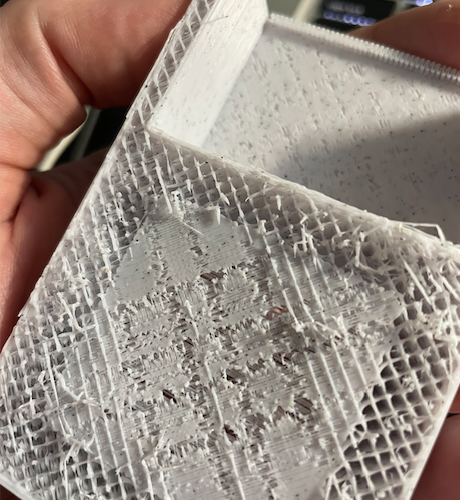

My Prusa Mini + has been working great until recently. Certain prints tend to fail. I've attached a photo of the most recent failed print. When it gets to that infill portion of the model, the infill begins to crack / split apart, and the print fails. I have performed several cold pulls and the nozzle appears to be fine. I also recalibrated my Z height, which also appears to be fine. Any ideas? Any help would be appreciated. Thanks

RE: Failed Prints on Prusa Mini+ . Potential Under Extrusion?

The spongy texture is a definite sign of under extrusion. It seems that after awhile of using the PTFE tubing in the hot end shrinks, a gap forms at the bottom that fills with molten filament which messes with your extrusion. This page talks about how to correct that: https://www.help.prusa3d.com/en/guide/how-to-replace-a-hotend-ptfe-tube-mini-mini_119449

In may case I had a problem with step 7 that I was never able to fully correct. My solution was to replace the heat break with a Bondtech heat break. I don't think that would have been necessary had I been successful at step 7.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit