RE: PrusaSlicer hard to remove supports

Thanks Joan, I had missed the post adapting the parameters to the new settings. Everything is clearer now.

Thanks anyway

RE: PrusaSlicer hard to remove supports

Following up on this. Would you please upload a snapshot of all your settings? Appreciate it.

I am out of town for 10 days. I will do so when I return.

RE: PrusaSlicer hard to remove supports

yes, please make a Screenshot with Prusa 2.4.2

RE: PrusaSlicer hard to remove supports

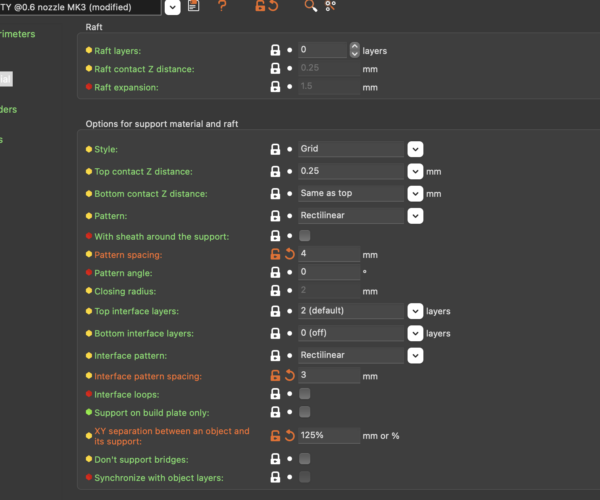

Here you go.

--------------------

Chuck H

3D Printer Review Blog

RE: PrusaSlicer hard to remove supports

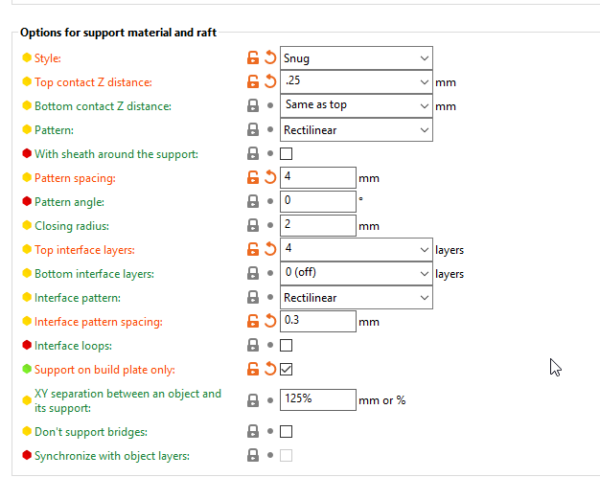

In my book yes, personally I wouldn't have the interface that widely spaced. Many support settings come down to personal preference but I also increase the interface layers from 2 to 4. I find that printing a thicker section of interface makes it easier to remove in one piece as it doesn't break up as much and will sort of peel off easier.

RE:

Thank you very much @bobstro .It worked very well for Colorfabb TPU Varioshore.

Any suggestion on how can I improve the surface quality after removing supports?

Thank you in advance!

RE: PrusaSlicer hard to remove supports

I have noticed that PETG seems to fuse more than other filaments.

I am trying to print one of these:

https://www.thingiverse.com/thing:4600247

I guess I need to adjust my orientation.

--------------------

Chuck H

3D Printer Review Blog

RE: PrusaSlicer hard to remove supports

I printed out of ASA with Bob's settings, and it is almost perfect. Just a little cleanup on the overhand. The enemy of good is better.

--------------------

Chuck H

3D Printer Review Blog

RE: PrusaSlicer hard to remove supports

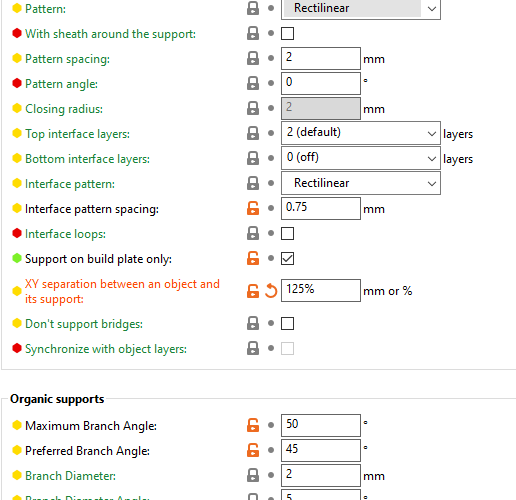

I read somewhere that top interface layers need to be zero for organic supports, I can't seem to find where I read this though...

Has anyone played around with settings for the organic supports yet? Trying this at the moment but they're still a bit hard to remove:

RE: PrusaSlicer hard to remove supports

You read it in the release notes.

"The Organic supports currently pose the following limitations:

For large models with a lot of supports, 16GB RAM minimum is recommended.

Top / bottom vertical separation distances are rounded to multiples of layer height.

Variable layer height is not supported.

Interface layers are not always produced reliably. As of now printing with zero interface layers is recommended, which produces easy to remove supports.

Rafts with Organic supports are buggy."

RE: PrusaSlicer hard to remove supports

OK thanks. I missed that part of the release notes.

RE: PrusaSlicer hard to remove supports

I plan to look at these those week. I would appreciate anyone with good settings for supports.

You read it in the release notes.

"The Organic supports currently pose the following limitations:

For large models with a lot of supports, 16GB RAM minimum is recommended.

Top / bottom vertical separation distances are rounded to multiples of layer height.

Variable layer height is not supported.

Interface layers are not always produced reliably. As of now printing with zero interface layers is recommended, which produces easy to remove supports.

Rafts with Organic supports are buggy."

--------------------

Chuck H

3D Printer Review Blog

RE: PrusaSlicer hard to remove supports

You forgot to mention what material you were using with those settings. PLA behaves different to PETG for example.

RE:

Apologies. It didn't allow me to edit past 5 minutes or so and I got distracted with another task afterwards and I felt annoyed at having to retype this out again.

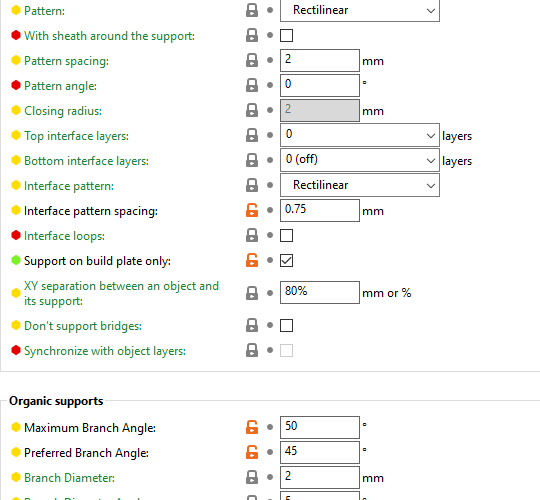

Overture PETG (White), 0.6mm nozzle, 0.25 layer height. Tested on 0.75 extrusion width, 230/235C temperature settings. Extrusion multiplier 14, most speeds on 70 mm/s. Small perimeters 56%, External perimeters 77%, Top solid infill 45%.

To get bridging right I had to slow the dynamic overhang speeds to 10/10/15/20 and to disable the 'don't support bridges' option. Fan cooling is 100% for overhangs. Otherwise the prototype was leaking water.

To reduce print times increased the angles to 45/50 for preferred/max. In total this profile brings down print times from 22h for my print to 9h40min or so - inclusive of supports. Otherwise 7h vs 10h stock (0.3mm stock, just changed layer height to 0.25 and sliced). Still optimising but acceptable quality, at least for my prototyping. Attempting a new print as we speak with 0.9mm width and 80 mm/s; other settings as stated above. Hopefully all goes well.

Hope that helps.

Zhao.

RE: PrusaSlicer hard to remove supports

OK, I can't edit the thing anymore because my previous post is awaiting moderation. I can appreciate why this is implemented but that doesn't make it any less bloody annoying. There was an error in my previous post - its not extrusion multiplier that's 14, its max volumetric speed @ 14. Extrusion multiplier used is 1.05.

RE: PrusaSlicer hard to remove supports

I came to ask the same thing with 0.8 nozzle kinda lost honestly.

I'm using bobstro settings anyways with organic supports.