RE: PRUSA edition heat break easily jam/clog with PLA

You can order directly from E3D or resellers in your area.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

https://www.amazon.com/Genuine-E3D-Break-1-75mm-V6-175-BREAK/dp/B077Y2MHW8

https://e3d-online.com/products/v6-heat-break (it's the 1.75mm diameter)

Or shop for their Titanium version, which is a lot better when printing above 215c.

https://www.amazon.com/gp/product/B07B693GG6

ps: Bob., it's weird, I didn't even see your post until after mine posted.

https://e3d-online.com/products/v6-titanium-heat-break

RE: PRUSA edition heat break easily jam/clog with PLA

https://www.amazon.com/Genuine-E3D-Break-1-75mm-V6-175-BREAK/dp/B077Y2MHW8

https://e3d-online.com/products/v6-heat-break (it's the 1.75mm diameter)

Or shop for their Titanium version, which is a lot better when printing above 215c.

https://www.amazon.com/gp/product/B07B693GG6

ps: Bob., it's weird, I didn't even see your post until after mine posted.

I have to concur with Tim. If you are in the US, you cannot bean Amazon print with the shipping speed.

Another good option in the US is Filatruder: https://www.filastruder.com/collections/e3d-spare-parts-and-accessories

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

@tim-vidoni

Here is: https://e3d-online.com/collections/printer-parts-mechanical/products/v6-heat-break

Pay attention to add to the basket the 1.75mm version 😉

Regards

RE: PRUSA edition heat break easily jam/clog with PLA

You may not need the expensive Titanium heatbreak.

Here is the standard stainless steel version:

https://e3d-online.com/v6-heat-break

E3D claim better performance with their Titanium heatbreak, but from what I have read on the forum, it does not seem entirely too certain, that this claim is true.

The heatbreak delivered by prusa is stainless steel.

I'm having this same issue and since I dont plan on using the MMU, I'm going to swamp things around. Just to make sure I'm getting the correct part, this is the only thing I need to replace: https://e3d-online.com/v6-heat-break ?

Will I still use the small PTFE tube that is in the original Prusa V6 Hotend?

RE: PRUSA edition heat break easily jam/clog with PLA

@cruise-sam

In my printer I kept the "larger" tube, that has a slide internal diameter of 2.2 mm, since I use MMU2.

But feel free to test how it goes for you.

Regards

RE: PRUSA edition heat break easily jam/clog with PLA

@tim-m30

Thank you!

RE: PRUSA edition heat break easily jam/clog with PLA

Just an update... I have had about 48 hours of PLA printing time without a single E-Axis jam or click since replacing the heatbrake with a 2mm E3D original.

So it seems that for me, the problem was entirely the Prusa 2.2mm->2mm heatbrake with the PLA I was printing with.

RE: PRUSA edition heat break easily jam/clog with PLA

Can the 2mm heartbreak be used in the MMS2S configuration?

Also, this wasn't happening before a couple months, any ideas why now? I did not change my filament brands so I wonder what this is causing issues suddenly

RE: PRUSA edition heat break easily jam/clog with PLA

[...] Also, this wasn't happening before a couple months, any ideas why now? I did not change my filament brands so I wonder what this is causing issues suddenly

There can be many causes of these extruder clicks and jams. Common resolutions I've seen include:

-

Improve cooling in ambient printing temperatures in excess of 40C. The E3D V6 hotend used on the Prusa Mk3 is an air-cooled design rated to 40C ambient temps. Above that temperature the efficiency of the cooling is reduced, possibly leading the temperature build-up in the hotend which can cause low-temperature filaments like PLA to soften prematurely, leading to jams.

-

Reduce print speeds. Often times, simply reducing speeds will resolve such issues. The hotend can only melt and move so much plastic per second, and different plastics have very different flow characteristics.

- Insufficient print temperature. Sometimes just adding 5-10C of heat helps some plastics flow much more freely. This ties into the hotend volumetric capacity as well.

- Ensuring the extruder idler gear is properly seated and able to turn freely. Any friction in the filament feed path can contribute to heat problems.

- Ensuring the extruder tension is appropriate. Too low and filament can slip. Too high and filament can be distorted and have difficulty feeding.

-

Obstructed filament path due to alignment or damaged filament (possibly due to extruder gear tension), PTFE, heatbreak, or nozzle damage.

-

Stuck filament cleaners, stuck spool rollers, or other attachments obstructing filament feed. (Had a spool that had melted together during drying that definitely contributed to this.)

-

Excessive retractions (particularly more than 2mm with the direct drive extruder). Lots of retractions in small detail areas can cause a lot of filament churning up and down which can cause heat build-up and friction.

- Reducing de-retraction speed. I use 50mm/s retract and 25mm/s de-retract. PLA is a particularly viscous plastic when melted and non-Newtonian behavior can add to back pressure. This is likely exacerbated with the 2.2-2.0mm step.

-

Adding thermal paste at the top of the heatbreak threads that screw into heatsink, leading to improved cooling efficiency and lower temps above the transition zone in the heatbreak.

-

Reducing thermal shock caused by an improperly aligned cooling fan duct directing air at the heater block and causing it to cool suddenly.

-

Replacing the Prusa-fied E3D heatbreak with the 2.2-2.0mm step with a smooth 2.0mm version. This is not recommended for the MMU2 by Prusa, but is a brute-force fix in some cases.

- Tweaking extruder motor current. I believe one of the firmware updates in the last 6 months addressed this. It's an issue that has popped up before with the Mk3. Too low and you get skipping. Too high and you get extruder motor heat.

If you were able to print well previously, I would definitely check out other contributors before simply swapping out parts.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

It's a stock MK3S + MMU2S. And using the default Prusa profiles. Only changes is I adapt the temperature for the filament brands I use. But, as mentioned, it used to work well but not I get constant jams and even tried with zero retraction as a test on PLA and while it went further than previously, it did jam.

RE: PRUSA edition heat break easily jam/clog with PLA

@louis-s4

Could it be possible the thermal paste on the heat pipe has worn out?

RE: PRUSA edition heat break easily jam/clog with PLA

Heat paste does not normally dry out after application: it is considered permanent. There is an odd chance the paste was bad or not applied correctly, but even this is remote. The active ingredient in the paste is the solids, and even if the carrier oil evaporates, it is only intended to make spreading the paste easier: and if the carrier oils go away, the active solids remain.

RE: PRUSA edition heat break easily jam/clog with PLA

Just found this, and am wondering if using the older hotend with the 2.0mm constant width will still work with the MMU2 when I upgrade to that?

I have gotten pretty good at clearing jams without disassembly. Set the printer to preheat a higher temp filament like ASA or ABS, Use a .4mm nozzle cleaner and stick it up the nozzle as far as it will go. Let it heat up and the nozzle will eventually heat the cleaner up past the heat break, which will melt the jammed up filament, then open the idler cover door and use a long 1.5mm allen key down through the filament feeder to push out the frozen filament jam.

RE: PRUSA edition heat break easily jam/clog with PLA

@dingo-aus

4 hours left on 20 hour print, it appears to have fixed it for me too! very happy.

RE: PRUSA edition heat break easily jam/clog with PLA

@jlnemec93

I have the same question since I have a MMU2S as well. What is the official stance on this for the MMU2S, does it work fine with the default E3D heartbreak or does it required the Prusa version?

@tim-vidoni

Do you have the MMU2S?

RE: PRUSA edition heat break easily jam/clog with PLA

I finally got a troublesome print to complete last night. I left the door to my enclosure open, sliced it at .15mm layer height instead of .10mm, and I turned the nozzle temp up to 230C.

My failures only seem to happen on models with lots of retractions, and not all PLA filaments, the Prusa Galaxy Silver never seems to have a problem, but the Crystal Clear Ice Blue PL is very particular. https://shop.prusa3d.com/en/filament/221-pla-crystal-clear-iceland-blue-750g.html

RE: PRUSA edition heat break easily jam/clog with PLA

Wow. I have same problem. 2 years, around 8000m of filament I didn't have any problems. Now I have big issues with print anything on PETG and PLA. I changed Heatbreak to E3D original, PTFE and nozzle to brand new. Problem stay.

Why is possible that works 2 years like total automatic printer - click and forget at now I can't make anything...

Bondtech solves this problem??

Cheers!

RE: PRUSA edition heat break easily jam/clog with PLA

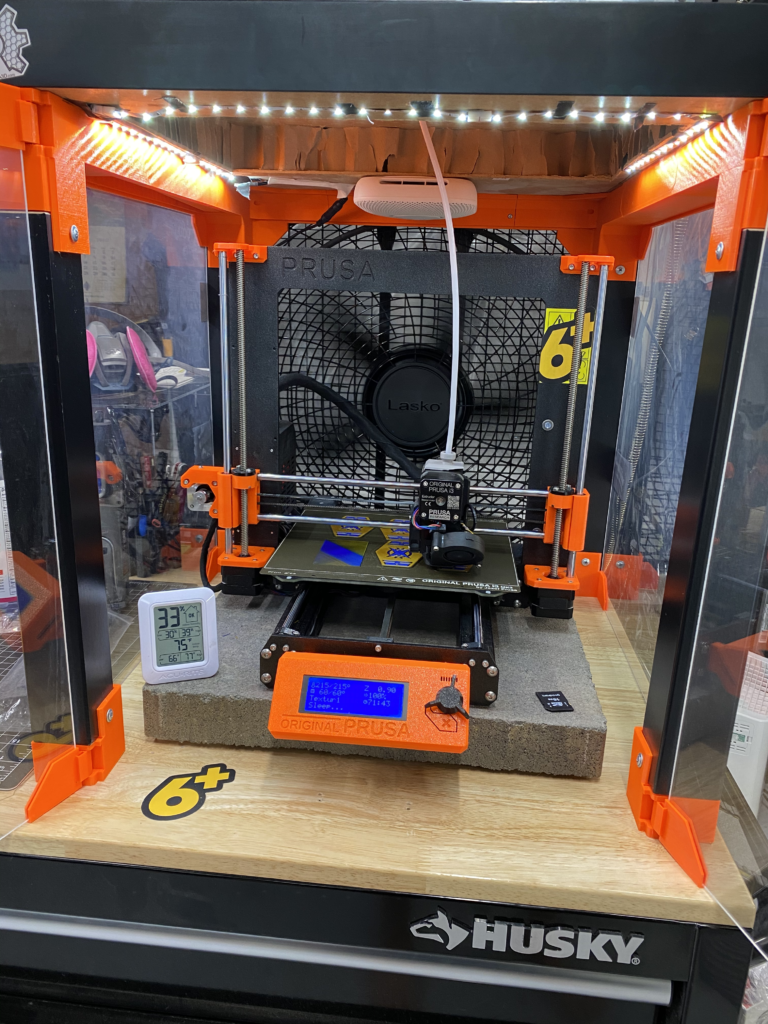

I have fixed this issue universally. I live in California, and while my printing space isn't unseasonably warm, I do have my Mk3s+ in an enclosure. I was unable to print with PLA at all for over a year.

My fix? I pointed a box fan on medium toward the print enclosure for the entire print. No clogs. I've done 50+ PLA prints this way since. Simple stuff, and complex multi-material stuff with tons of retractions. Everything works seamlessly now. (Pic below).

I've even now added a box fan and a dust filter to the back of the enclosure itself so that it's out of the way. The fan pulls air through the filter and blows it through the enclosure, so I have less chance of dust contamination than my previous setup (which was just a fan balanced on a chair). I have noted that both my fans on "low" did not cool enough to work. The bare fan on medium did the job, and the fan with the filter needs to be run on "high," so there does need to be a decent amount of air moving. So far this setup has allowed me to print PLA when my shop is up into the high 7os (F). My shop peaks at about 80 in the summer, so I think this setup will keep working.

Printing with PLA? Turn the fan on. Printing with other stuff: dont turn the fan on.

Thats it.

Cost: $18. No need for exotic unobtanium heat breaks.

RE: PRUSA edition heat break easily jam/clog with PLA

[...] Cost: $18. No need for exotic unobtanium heat breaks.

Funny enough, a Titanium heatbreak runs about $18. Just as well, though. From your description, your problem sounds more like "upper" extruder heat issues, usually compounded with extruder heat. Reducing heat from the "lower" hotend wouldn't matter much in that case. Does your extruder motor get hot to the touch (as in near-burning heat)?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan