Underextrusion on internal layers?

Hi.

I just got my first 3d printer ever - MK3S+ kit assembled and calibrated. Got my first print out just fine and on a second print I noticed something interesting.

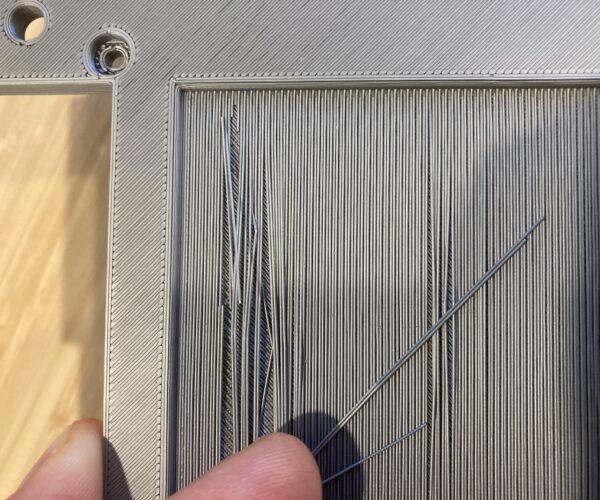

The lines within the inner layer sometimes do not touch each other on the big surfaces.

It didn't happen to the first layer. It doesn't happen to small surfaces either (under 20mm in diameter)

I'm not sure if this is "underextrusion" or is it expected?

Printer: Newly assembled MK3S+ kit

Material: Silver PLA that came with the printer (Prusa PLA?)

Slicer settings: "0.20 mm Speed" with added support.

Print speed: 100%

Temp: 215 C / 60 C

Before I start disassembling the extruder, I wanted to understand if this is normal or not. And if this is an issue - how is it called and where to start looking for a solution - software, hardware, slicer settings, or the filament?

P.S. I tried searching the forum a bit, but since I'm new to the terminology, I guess I didn't use the right words? Other "underextrusion" examples I found were quite severe, not like mine.

Thanks!

~Max

RE: Underextrusion on internal layers?

Quick answer: no, not normal. If you are using default settings and haven't played with temps speeds or extrusion widths or other filament settings like extrusion ratio... infill should be just that.

Could be a number of things: from your slicer settings (save the project as a .3MF file, zip it up and post here, folk can review your settings). To nozzle clogs or low temps or Bondtech idler tension being too light and printing too fast.

Easiest is to post your project, and start there.

RE: Underextrusion on internal layers?

Also - any chance you hear "clicking" at the extruder when printing?

RE: Underextrusion on internal layers?

Thank you, Tim!

I've attached the model, 3mf, and gcode to this post.

There are no clicking sounds while printing.

RE: Underextrusion on internal layers?

A couple of things. When printing overhangs, there is nothing for that first overhand layer to print on. Extrusions will not look full. They'll look like logs stacked together. I suspect that is what your photo is showing. And, it can take a couple of layers before the print fills in well.

If it were me, I'd find a way to camfer the mounting holes so the don't need support, and then remove the interface layer, set vertical contact to 0.01 mm (almost full contact), and pattern spacing to 5 mm. You'll get a layer difference that looks like these two examples:

from this:

to this:

Here's a sample ... but it won't work well with the mounting holes as designed. But shows the support settings to get a better flat surface quality. Note I missed setting the interface to 0.01 mm.

RE: Underextrusion on internal layers?

Thank you, Tim!

I'll try doing what you suggested and see what changes it'll bring.

I'l also try printing something very simple (like a cube) with several filled layers at the bottom to see if the issue happens when supports are not in the equation.

In my original print I used supports, and the very first picture in the thread refers to the third diagonal layer after the support.

Here are a couple pictures of how things looked beneath it.

Very first layer: You can see the support, and actually minimal "under-extrusion" on the right (I was wrong that it didn't affect the first layer. from above it looked fine, but after being removed from the bed - it seems there are some minimal gaps.

After the support is removed: Last layer of the support can't be removed with out a knife, but it's completely "in the air"

First layer after the support: You can see how sparse it is.

RE: Underextrusion on internal layers?

All three photos show exactly what to expect printing large bridged structures using stock settings.

FDM printers just do poorly when printing in thin air. The slicer expects extrusions to be 0.45 mm wide, but when printing in air the 0.40 mm nozzle only extrudes 0.40 mm or less (gravity takes over to thin the extrusion).

This is why there are soluble support materials.

To minimize material waste, slicers have the option to print support structures with the part material. These structures must be separated from the part with a gap, otherwise they weld. Thus, these structures must be tuned to the specific part conditions to work well. Especially when printing large flat areas (almost the worst case, imo). This gap means the printer is really printing into free space.

So it isn't a problem with the printer. It is a simple problem with a part not really designed for FDM printing.

RE: Underextrusion on internal layers?

Thank you, Tim for a great explanation! It helps me a lot!

RE: Underextrusion on internal layers?

I apologize for bringing this up again, but I think there are other issues, in addition to my mistakes with support and bridges.

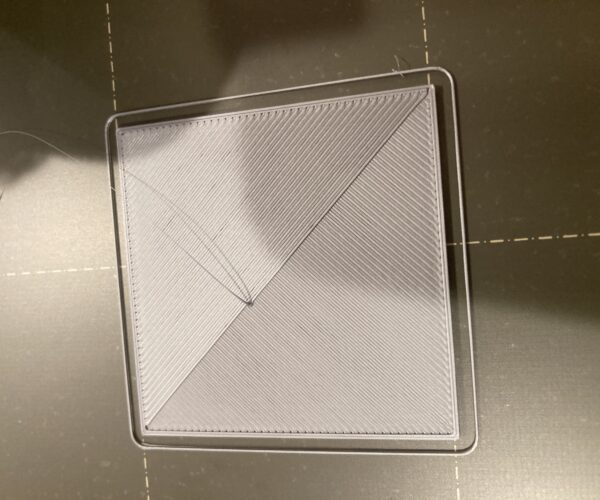

I just did some tests, to see how it prints on solid infills.

So I made a 50 x 50 x 3 mm cube, and printed it in PLA (which came with the printer) ~ half way (up to 1.6 mm) with solid layers only (no partial infills, no voids) in 3 different presets:

- 0.20mm SPEED

- 0.20mm QUALITY

- 0.15mm QUALITY

In all three settings I see a varying amounts of under-extrusion. Interestingly enough, 0.15mm isn't the best of them.

0.20 mm SPEED

Project: box_50_50_3_0.20_speed.3mf

0.20 mm QUALITY

Project: box_50_50_3_0.20_quality.3mf

0.15 mm QUALITY

Project: box_50_50_3_0.15_quality.3mf

So what I get is that the slowest and supposedly most precise setup is getting the worst results.

Should I assume that this is not OK? If so, any hints if this is a hardware or software or slicer settings?

These are my 3rd, 4th, and 5th prints on this printer, and in my life. I hope it's my mistake again (like I did with the supports & bridges) and not the printer 🙂

Thanks again for all the help!

RE: Underextrusion on internal layers?

A small follow up:

I also printed a 10 x 10 x 8 mm volume on a completely default settings at 0.15 QUALITY present and it came out great externally. Top layer has no issues. I didn't follow on it when it was printing so I don't know how it did internal layers.

Perhaps the size or the external vs internal layer makes a difference too?

RE: Underextrusion on internal layers?

What you are showing there is not normal. There is something affecting the flow. Solid layers should have extrusions welded together into a solid.

We can start with basic extrusion and multiplier tests.

Test 1) - basic filament drive test

- Using PLA, preheat to PLA print temps.

- Raise the extruder to about mid level - 100mm up is good.

- While the printer is heating, mark the filament at the top of the extruder, and every 5 cm for about 20 cm. I use a Sharpie. I also mark 5 mm either side of the 100 mm mark.

- When the printer is up to temp, using the Settings/Move/E-Axis menu, extrude 100 mm of filament (just add 100 to the value on screen).

- -- You may need to practice which way you turn the knob. Be sure to turn it only one way - and do not overshoot the 100+ because turning it back will mess up the test.

- Watch the marks to count how many cm are extruded.

- Wait for the extrude to finish - the process is rather slow to catch up.

- Compare the value you entered to the value of filament actually used. They should match within a millimeter.

Test 2) - Extrusion Multiplier

Scroll down and use the PRECISE METHOD in this guide.

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257/

You'll need to download and slice this cube:

https://cdn.help.prusa3d.com/wp-content/uploads/2021/04/cube-40-40-40.zip

The idea is to print a hollow cube 40x40 mm. Then measure the wall thickness. This tells you precisely how well the printer is extruding filament. External perimeters are typically set to 0.45 mm, and the cube should measure 0.45 precisely.

Once you have the numbers from these two tests... they may hint at an underlying issue.

RE: Underextrusion on internal layers?

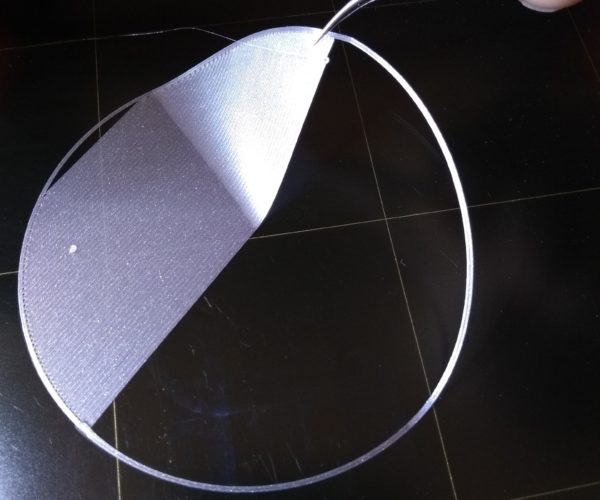

As a data point, the first layer should look something like this test coupon. A solid sheet of plastic (this one has a few gaps, and isn't perfect, but is good enough to show concept).

And here's your test coupon I just printed using your settings - Prusament 0.15 Quality (but my Mk3 my printer profile). This is about 5 layers up.

RE: Underextrusion on internal layers?

In another thread having similar issues ... it occurred to me it might be as simple as the Bondtech idler tension screw. Have you played with making the idler tighter? And have you heard any odd clicking or snapping sounds coming from the extruder?

Also - check to ensure the axle on said idler is centered in the door dogs. Used to be a common issue - the axle is too short and would fall off one side and give spring to the idler gear and cause the Bondtech set to not have enough traction. A quick test it to push in on the idler door - if there is any give, check the axle. I'd open up the door and check the ends anyway... just to be safe.

The axle needs to be centered - below the surface on both sides. If flush on one side, it can fall out of the other.

RE: Underextrusion on internal layers?

@doctorshtein

Hi, I am having what looks to be the same problem as you, when did you receive your kit? ...my order date was the 10th March, shipped 30th March and received on the 31st.

Also can I ask, are you letting the printer cool right down before switching off?

and if you reload the PLA and try a to print does that work ok? as I found reloading makes it work again.

I have a forum thread here https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/cant-get-pla-to-print/#post-429634

I am just putting a new temp sensor in, and will run some prints again.

RE: Underextrusion on internal layers?

Folks, sorry for a delayed reply. I wanted to do all the tests before I post back.

First of all - thanks again for all the help!

So, here're the results:

Test 1: Basic filament drive test

I tried it several times, before any printing today, and after a print that proved the issue is still there. Both cases - it extruded super close to 100mm.

Test 2: The cube.

My caliper is probably not the best one, but it showed consistently 0.43 mm - 0.44 mm. Thicker at the bottom and near the cube's edges. I'm re-printing it again with the multiplier adjusted right now, will post the results back asap.

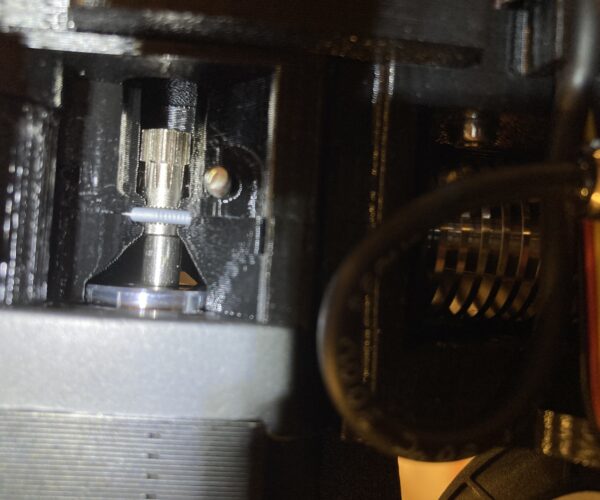

Test 3: Idler's axel

It sits perfectly in the middle

Test 4: Idler's tension:

I had a bit o a tighter side (screw head is ~ 1.5 mm below the surface), so I tried both: making it even more tight, and making it looser. Both changes didn't make significant difference. Although, when I tried making it looser, I started hearing low pitch, deaf "clicks" and slight vibrations from the extruder. When tightened back - no sounds or vibrations.

I also took a picture with the door open, to show that the gear leaves small marks on the filament. Wonder if that's expected?

@mattj

Thank you for sharing your post. The issues indeed seem very similar. Hope the thermistor solves it for you! At least we'll know the solution to your case.

My printer was ordered ordered on March 16th, and was shipped in April 7th.

wrt letting it cool down - i do to at least 30 C.

Reloading the filament helps improve it a bit, but doesn't solve it completely.

RE: Underextrusion on internal layers?

@doctorshtein

At this point - contact Prusa using the store chat. There's probably a wait time; but stick with it. You have a warranty for a reason, may as well use it.

RE: Underextrusion on internal layers?

Will do, and will post back once I get it resolved.

Thanks again for all the help! Without it I would've not known what to do at all!

On a separate note - the box still printed at 0.43 - 0.44 mm, as if the multiplier didn't have any effect. perhaps it was too tiny of a change?

RE: Underextrusion on internal layers?

What's weird is the box walls are printed at spec (0.45 coming out as 0.43-0.44 is a bit low, but fair) - yet when layered side by side it seems your printer isn't printing them even at that size. Keep the info handy - Prusa techs will want to know these results.

RE: Underextrusion on internal layers?

A very quick update.

TLDR: So far - no luck.

I've spent ~16 hours with support so far, and nothing solid. We've re-assembled the extruder several times, did many cold pulls and test prints, as well factory resets, re-calibrations, new firmware, etc.

The closest thing we came to is that it's temp related. We've tried test prints with different fan speed settings, higher nozzle temp settings, and higher flow rates. It becomes much better with the fan being slower and(or) flow being higher, and very slightly better with the temp being higher by 10C. Nothing fixed it completely though.

I guess I'll be trying the suggestions from another thread as well (to print with 10% higher speed, and 10C less temps to see the delta), and will be going back to support chat on Monday.

RE: Underextrusion on internal layers?

@doctorshtein

This is something that came out about the Mk3S fan shroud some time back. It was very easy to point it too high and it was blowing directly on the heater block, not to the point just below the nozzle where it should.

A good photo of that aspect of the hot end might help.

ps: the feedback was the nozzle would drop 10c any time the fan turned on, and PID cals weren't enough to stop the drift. Adding a sock to the heater block was one way to reduce the issue.