Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

My current problem is the step in XYZ calibration (I think) where it asks to put down a piece of paper. The paper keeps getting moved and caught.

Previously I got past this step but when it printed the pattern on the plate it wasn't even close to adhering, all of the right angles became curves, and the block of filament it should have made after the zig zag was a clump on the extruder. Felt like that could have been fixed by a z level offset, but it looks like I'm not allowed to set a negative one?? The problem was clearly the nozzle was uniformly a bit too high from the bed. Felt like I could have overrode the

I've been googling around a lot and it's unclear what to do, which is very frustrating. If an error code appears on the machine, seems like there should be an article on the site for it.

My current guess on what to do is based on:

- This thread: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/nozzle-catches-the-paper-during-xyz-calibration/

- And walking through this and getting a sense for how the pinda sensor works: https://help.prusa3d.com/article/pinda-probe-testing_2091

I think the problem is the pinda sensor height isn't what it ought to be, and since the paper is getting caught it needs to get closer to the bed.

Figuring out what it ought to be has been very difficult. Every time the paper drags I try to move the sensor a little, but it'll inevitably move more than one click (made from threads on the sensor and the plastic clamp). After it's moved too much I can't remember where it was before I moved it, I've probably tested 8 times at this point and I'm wondering if there is a correct position.

After seeing I could see if the pinda sensor is sending a signal or not, I tried adjusting the pinda sensor while I could see if it was sending a signal or not. I got it to the furthest point from where it sent a consistent positive signal with the filament on the bed and that drug paper.

Is there some trick to this that I'm missing? Am I on the right track that it's probably the Pinda senor height? Does this sound like some other problem? Or a bad part?

I'll report back if I get anywhere :/

Best Answer by JoanTabb:

Is it OK if the paper moves...?

this depends why the paper moves...

If the paper is a nice flat sheet that lays close on the surface of the build plate, then YES it does matter if the paper moves, because you are only a paper's thickness away from scratching your build plate...

if the paper is wrinkled, and the nozzle is catching a high point... then it doesn't matter. but it's time to find a better sheet of paper... 🙂

the thread on the Pinda is a 1mm pitch (M8 Fine thread) so one click is 1mm.

If you have been tinkering for a while, it might be worth leaving the printer for a while, maybe overnight, and have another go later / tomorrow...

when you get frustrated, you tend to make errors.

the curves and blobs that you report, indicate a high nozzle...

I Don't like the Prusa First Layer calibration tool...

I have used the

Life Adjust 'Z' My Way, process for years, it's simple, and works...

there are test files at the bottom of the first post.

However, you can simply use the first layer of the Prusa Name plate, as a first layer calibration model. (Just stop the print when you get to the end of the first layer.

being an oblong, instead of a square, the printed surface becomes visible, more quickly than the square.

remember, you can adjust the Live Z value as the print continues...

By now you have tried lots of things, and you MAY have contaminated the build plate... so I will suggest a number of things to hopefully get you going successfully.

I after a break, re adjust the nozzle / Pinda relationship. IIRC... with the printer turned off, rotate BOTH X lead screws in the same direction to lower the nozzle, until it 'Just Touches' the build plate, then adjust the pinda so that it's tip, is the thickness of a small prusa cable tie, above the build plate. and tighten the pinch screw to hold the Pinda in place

then turn the printer on, once the display shows the extruder and heatbed temperatures (Room temperature), Click and hold the LCD Control knob until the screen shows Z: o.oo or what ever, and rotate the knob until the Z value, is say 20mm, or more...

then remove the Build plate, take it to the sink, and give it a really thorough wash with hot water and dish soap, then rinse well with hot water, and dry immediately with plain paper towels. (I dedicate a new kitchen sponge, to my printer build plates, to prevent it getting greasy...

then I use the LCD Control, to select 7x7 mesh bed levelling, this tests 49 points on the build plate, instead of the normal 9 points (I also turn on the avoid magnets option (Can't remember what it's called offhand) this avoids 7 of the 49 values because they are near the magnets in the headbed)

I find this works best for me.

then I replace the build plate, (taking care not to get finger grease or other contaminants on the build surface...

(It's surprising how much a fingerprint can reduce adhesion)

then I would run the Life adjust 'Z' My Way patch, or the Prusa Nameplate patch, and adjust Live Z as it goes.

if you have set the pinda properly, your nozzle should start off, well above the build plate, and you need to adjust Live Z to a negative value

Live Z cannot got Positive...

larger negative values move you towards the build plate, smaller values move you away from the build plate

each click on the LCD Knob, should move you 1/1000 of a milimetre in one direction or the other... and in the beginning, you just get spaghetti...

KEEP going...

Eventually you should start to get filament sticking on the build plate, and it will look like wobbly spaghetti.

Keep going

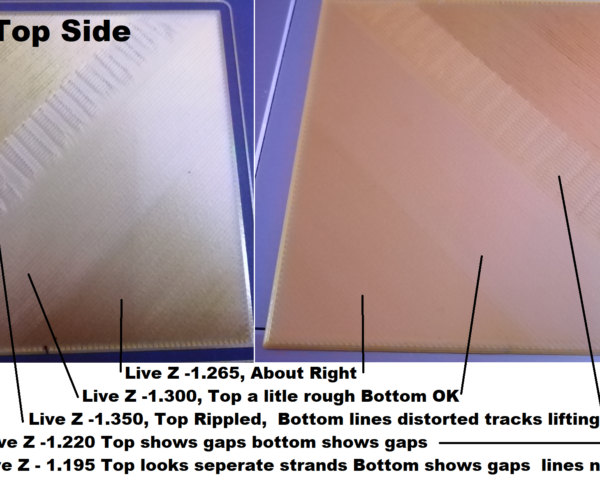

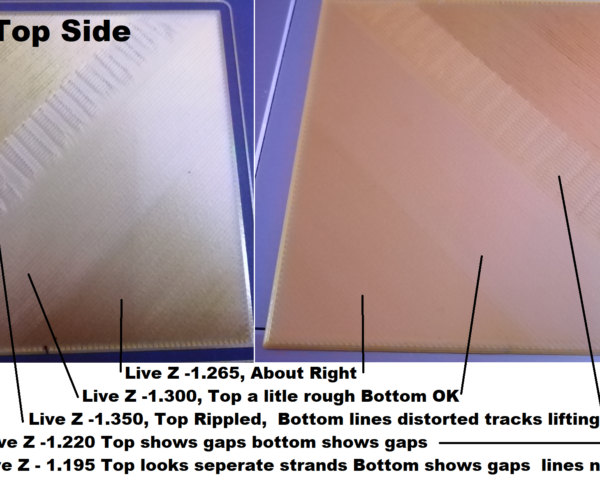

shortly you will begin to see individual lines forming, with gaps between them...

Keep Going...

then the individual lines will look uniform but separate...

Keep going....

after a while, the lines will begin to merge into a sheet

NOW you are getting somewhere near perfect...

Keep going...

very soon, you should get a nice smooth top with the strands nicely squished together into a single sheet....

This is just about perfect...

IF you keep going, the top surface will start to become rough...

IF you keep going, the strands will begin to distort and start to form a rough, rippled surface on the top and if you lift the patch off the build plate, the underside will show distorted lines with gaps where they have lifted off the build plate (reducing adhesion)

YOU have now gone way too far...

the image above may help you recognise the different stages, the actual values are unique to my printer, yours will be different...

but the differences between the value for too high, just right and too low are relatively small....

so you need to hunt for the initial adhesion point, fairly quickly, then slow down the Live Z changes to get the results just right...

Regards Joan

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

Follow up question, is it ok if the paper moves a tiny bit? I've been operating under "shouldn't move at all".

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

The problem was clearly the nozzle was uniformly a bit too high from the bed. Felt like I could have overrode the

Sorry, didn't finish my thought, and I don't see an edit button.

Felt like I could have override the bed level height, but that felt like playing with fire, so I've avoided trying it so far.

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

Is it OK if the paper moves...?

this depends why the paper moves...

If the paper is a nice flat sheet that lays close on the surface of the build plate, then YES it does matter if the paper moves, because you are only a paper's thickness away from scratching your build plate...

if the paper is wrinkled, and the nozzle is catching a high point... then it doesn't matter. but it's time to find a better sheet of paper... 🙂

the thread on the Pinda is a 1mm pitch (M8 Fine thread) so one click is 1mm.

If you have been tinkering for a while, it might be worth leaving the printer for a while, maybe overnight, and have another go later / tomorrow...

when you get frustrated, you tend to make errors.

the curves and blobs that you report, indicate a high nozzle...

I Don't like the Prusa First Layer calibration tool...

I have used the

Life Adjust 'Z' My Way, process for years, it's simple, and works...

there are test files at the bottom of the first post.

However, you can simply use the first layer of the Prusa Name plate, as a first layer calibration model. (Just stop the print when you get to the end of the first layer.

being an oblong, instead of a square, the printed surface becomes visible, more quickly than the square.

remember, you can adjust the Live Z value as the print continues...

By now you have tried lots of things, and you MAY have contaminated the build plate... so I will suggest a number of things to hopefully get you going successfully.

I after a break, re adjust the nozzle / Pinda relationship. IIRC... with the printer turned off, rotate BOTH X lead screws in the same direction to lower the nozzle, until it 'Just Touches' the build plate, then adjust the pinda so that it's tip, is the thickness of a small prusa cable tie, above the build plate. and tighten the pinch screw to hold the Pinda in place

then turn the printer on, once the display shows the extruder and heatbed temperatures (Room temperature), Click and hold the LCD Control knob until the screen shows Z: o.oo or what ever, and rotate the knob until the Z value, is say 20mm, or more...

then remove the Build plate, take it to the sink, and give it a really thorough wash with hot water and dish soap, then rinse well with hot water, and dry immediately with plain paper towels. (I dedicate a new kitchen sponge, to my printer build plates, to prevent it getting greasy...

then I use the LCD Control, to select 7x7 mesh bed levelling, this tests 49 points on the build plate, instead of the normal 9 points (I also turn on the avoid magnets option (Can't remember what it's called offhand) this avoids 7 of the 49 values because they are near the magnets in the headbed)

I find this works best for me.

then I replace the build plate, (taking care not to get finger grease or other contaminants on the build surface...

(It's surprising how much a fingerprint can reduce adhesion)

then I would run the Life adjust 'Z' My Way patch, or the Prusa Nameplate patch, and adjust Live Z as it goes.

if you have set the pinda properly, your nozzle should start off, well above the build plate, and you need to adjust Live Z to a negative value

Live Z cannot got Positive...

larger negative values move you towards the build plate, smaller values move you away from the build plate

each click on the LCD Knob, should move you 1/1000 of a milimetre in one direction or the other... and in the beginning, you just get spaghetti...

KEEP going...

Eventually you should start to get filament sticking on the build plate, and it will look like wobbly spaghetti.

Keep going

shortly you will begin to see individual lines forming, with gaps between them...

Keep Going...

then the individual lines will look uniform but separate...

Keep going....

after a while, the lines will begin to merge into a sheet

NOW you are getting somewhere near perfect...

Keep going...

very soon, you should get a nice smooth top with the strands nicely squished together into a single sheet....

This is just about perfect...

IF you keep going, the top surface will start to become rough...

IF you keep going, the strands will begin to distort and start to form a rough, rippled surface on the top and if you lift the patch off the build plate, the underside will show distorted lines with gaps where they have lifted off the build plate (reducing adhesion)

YOU have now gone way too far...

the image above may help you recognise the different stages, the actual values are unique to my printer, yours will be different...

but the differences between the value for too high, just right and too low are relatively small....

so you need to hunt for the initial adhesion point, fairly quickly, then slow down the Live Z changes to get the results just right...

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE:

If you have been tinkering for a while, it might be worth leaving the printer for a while, maybe overnight,

This is day 2 T_T

if you have set the pinda properly, your nozzle should start off, well above the build plate, and you need to adjust Live Z to a negative value

Live Z cannot got Positive...

In the setup wizard it would not let me go negative 🙁 turning the nob one way would go positive, and no matter how much I went the other way it stopped at 0 and would not go negative. Maybe this might be a bug, I updated to the latest firmware before doing the first calibration, so it'd be in 3.11

It did start off well above the plate, I was really confused why I could only get further from it.

I came back to give an update, though so...

Update

I finally got another XYZ calibration that didn't move the paper, and I had the same result of a nozzle that was way too high. Unfortunately I hadn't seen @JoannTabb's response yet!

I went into Calibration > Live adjust Z, then I was able to set the Z level negative, and then in the wizard's "First layer calibration" allowed me to continue negative.

Having done this and now having read @JoannTabb's response, I agree that the wizard's Z leveling isn't very good. The zig zag pattern is not very helpful, and only at the end does it lay down a block of filament that gives you a decent sense of how close you are to a good z setting.

In short, I wish I would have found what Joann has said, instead of trying to use the "Wizard". That wizard needs to go back to wizard school.

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

This post should have a permanent place in the sticky list at the top of the forum pages.

Very clear, complete, and succinct directions for anyone new to the art of 3D printing.

Thank you @joantabb!

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

I believe the Prusa Wizard is a victim of the limited memory space in the einsy controller.

yes, you can get it to work, but no, it's not the easiest tool to use...

I think you may have been confusing two different Z axis movement options...

when the printer is switched on, but inactive, a long press on the control knob, will access the Z axis movement option. (After switch on, Z will always be considered to be at 0.00 mm, because the printer, doesn't actually know where the print head is, until it has done a 'Home Axis' or 'Home All Axis'

so after switch on, the printer LCD Control will only let you select values above 0.00mm, to prevent build plate damage.

the Live Z adjustment option is usually accessed when the printer is in the process of a first layer print... (you can also access it when the printer is switched on and stationary, using a different menu option. as you found out... ) this is all part of getting used to the printer...

Live Z can only ever go negative and is (I believe) restricted to values between 0.00mm and -2.00mm.

Different build plates will require different Live Z settings on the same printer

Changing the nozzle will require a re adjustment in live Z

Nozzle wear will require a change in live Z,

Different print / Bed temperatures may require a change in Live Z.

getting filament particles under the build plate, will affect live Z and probably cause a failed mesh bed levelling.

Getting the build plate in top of the stops at the rear of the heat bed, will affect Live Z and probably cause a failed mesh bed levelling.

welcome to the crazy world of 3D printing!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

I began printing with a Prusa Mk1 and gained experience with the support of other users.

Now I try to pay that support forward.

Life Support Z My Way, was written by a member of the forum whose first language was not English (Hence the possible spelling mistake)

It's a bit old now, but it still works. and I find it easy to search for, because of the spelling mistake... 🙂

unfortunately I cannot make it a Sticky.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Assembled MK3S+ kit, Can't get past the calibration without problems (nozzle to high, then nozzle drags paper in XYZ cal)

Unfortunately indeed, but I was referring to your reply to the OP, which contains so much valuable info, especially for someone starting out. That’s what should be sticky, as well as Jeff Jordan’s original ‘Life Adjust Z - my way’ post.

Maybe the Prusa forum gods will recognize the wisdom of such a thing and make it so. One can only hope.

Cheers