4 hour print of a self-sliced file with input shaping

Today I tried to print a more complicated part with input shaping. I chose this clip for coffee bags, because printing it without supports and adhesion enhancers (aka glue) tests several aspects of the printer, e.g. overhangs, tolerances, printing of small details, bed adhesion (the piece in the middle only has two perimeters on the print sheet). And if the print is successful you also have a useful part. 🙂

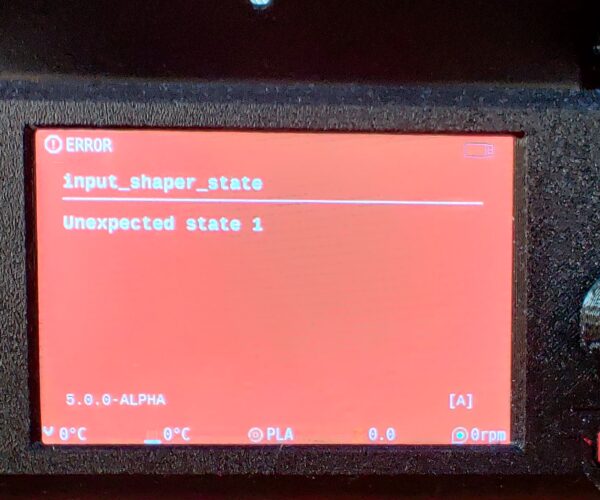

It took several trials to complete this four hour print. At first I tried to print it using OctoPrint and its arc welder plugin. I had several successful prints of simpler parts the same way before. That print failed after about half an hour with this red screen (I filed a bug report on github):

Then I eliminated Octoprint and arc welder from the process and exported the file from PrusaSlicer to disk and then copied the file on to the USB stick.

I had two more failed prints, each of them at a different stage in the print, and the third one was successful.

The print is fully functional, the hinges work, the clip snaps together and the threads for the cap work as well.

Repeatability of the print is not quite there, but I am sure this will get better. I also have some video clips of the printer at work on this, if somebody wants to see that.