Masters of printing TPU - what's happening?

Hi all,

I have a MINI since a year and I cannot manage to print with TPU. At the begging I managed to print few things, now it seems to not pull the filament correctly.

I tried to loose the tensor screw as much as possible, I am printing at 15 mm/s for all speed settings, flow factor at 115, nuzzle temperature 245 (for Filamentum 98A) and fan speed 0-60.

A the result is always the filament stop flowing constantly and sometimes even I have to push it into the gears. I cleaned the gear of the Bowden extruder.

The fist two layer start printing pretty good and then...

Any clue or suggestions?

Thanks.

RE: Masters of printing TPU - what's happening?

Take a look at some of these discussions:

It may be that the hot end is partially clogged and it is too hard to push the filament into it. If that is the case, no adjustment of the extruder will work, as it will just get hung up in the Bowden tube.

I've had good luck with Sainsmart. See my thread in this section.

Regards,

Mark

RE: Masters of printing TPU - what's happening?

Thanks Mark!

I'll checkout the discussion and drop here my progress.

BWT, Printing back PLA or PTEG is going okay, I suspect is not nuzzle obstruction, at least general obstruction.

RE: Masters of printing TPU - what's happening?

Yeah, this looks ugly.. First question when printing TPU: Did you dried the filament? I had really good results with Colorfabb VarioShore TPU with relatively long retractions of 12mm (!)

RE: Masters of printing TPU - what's happening?

Hi,

I actually found out that if I increase the flow ratio to 115 on the printer and the extruder temperature to 242-245C everything look much better. It is annoying to set the flow rate every print though.

Also, there is the same setting on PrusaSlicer but it does not change the printer settings, so basically does nothing and I keep changing it manually.

RE: Masters of printing TPU - what's happening?

Hey Daniel! How's the TPU printing coming along? I have just bought my first-ever spool of Overture's High-Speed TPU and I am in search of some pointers. I uploaded several TPU profiles onto the Prusa Slicer and I am going with the Filatech FilaFlex40 profile, so we'll see how it goes... I'll report back with any info! LMK if you think of any insights please!

RE: Masters of printing TPU - what's happening?

Hi Sanperez,

Sorry for the late reply!

As I said it's been going better by changing the flow ratio and temperature every time a print starts.

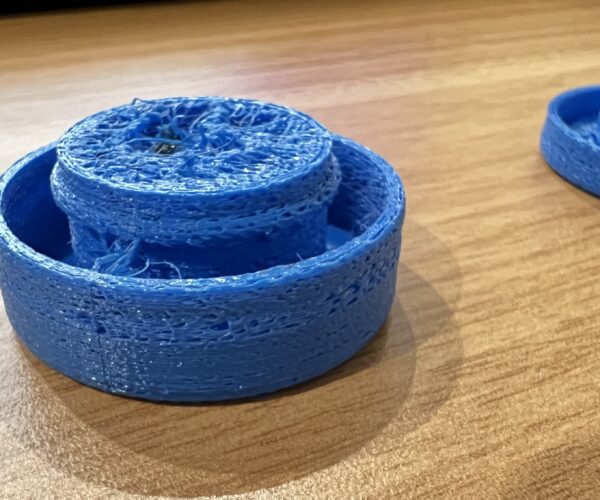

But so far I print okay, here an example, its a simpler model but I also printed a toroid and was good too.

RE: Masters of printing TPU - what's happening?

My two cents on Fillamentum TPU 98A and Filaflex 40, both of which are sold by Prusa, so those are the first ones I got, and I spent way too much time on getting both right:

- I think the Prusa standard profiles for both filaments have set the maximum volumetric flow rate too low. E.g., Filaflex 40 comes with 1.8 mm3/s, which on my setup yields a result similar to OP's pics. If I go faster than slower, eg at 5 mm3/s, the surface prints perfectly smooth, but there is more retraction leftovers at the seams. Fillamentum 98A works similarly. At these low limits, max flow rate is like a speed brake, and playing with this value is quicker/better than with speed and temperature. Also, both filaments are rather fickle in that they appear to need the perfect combo, and I think that they do not behave linearly. At some combinations of speed and temp and volumetric flow, they are perfect, at others less so.

- I was unable to achieve successful longer TPU prints with the Mini's original extruder. Irrespective of idler pressure, what would happen is that the filament would tangle itself around the pulley at -- I believe -- re-retractions after something like two hours printing, when everything in the printer was rather warmed up already. Was a nightmare to resolve each time it happened. I then switched to the Bondtech extruder for the Mini and had zero problems with TPU (re-)retractions since then. The reason for this is that while the Bondtech uses the same motor, it has two opposing metal gears biting into the filament, while the original Prusa extruder just has one gear which presses the filament against a flat PETG surface.

- If your goal is to go soft and perhaps sticky, stop trying with these filaments and get yourself some colorfabb Varioshore TPU. At least for my hobbyist use case, varioshore is incredibly good for achieving soft and especially sticky (high friction) surfaces. Both Fillamentum 98A and Filaflex 40 are not only more hard than soft (but they are flexible and super tough/sturdy, don't get me wrong!), they are not really sticky, surfaces are rather smooth and slippery. Case bumpers made with Filaflex 40 will not really prevent slipping, but with Varioshore at, say, 220 C they will.

RISPONDI: Masters of printing TPU - what's happening?

Hi!

You wrote here that you use Varioshore TPU.

I'm just starting to use it and don't know much about it, do you have some tips for better prints with high foaming (like 245°C)? should I use 15mm^3/s or 2mm^3/s? and whats the difference? I cant find any tutorials so I'd be greatful for some help.

Thx

RE: Masters of printing TPU - what's happening?

I have printed with tpu quite a bit now and have noticed a few things.

Printed on ender 3 with direct drive.

Used high speed tpu 98a

normal 98a

and 95a

all different colors.

Printing temp. 200c

has given me by far the best results I was printing in tpu at recommended temps on the roll 220c to 240c and would have poor layer adhesion and excessive stringing it acted as if it was wet. Then printed accidentally a file set for pla at 200c and noticed it was printing perfectly and had good enough adhesion that I couldn't tear the part apart. And it was clean almost no stringing I printed an articulated dragon so had many opertunities to string.

And print slow have patience better to print for longer than have a failed print. And spend more material and time in the long run.

So my suggestion is to start printing at lower temps and see if you can get it dialed in. The Pic you provided looks like my prints when I print too hot even 10c more can make all the difference in how it turns out.

And because there is margin for error on a thermistor and what my printed says is 200c might not be what yours says is 200c ypu will need to experiment. But across all the brands of tpu I have used which is about 4 lower temp was key. Hope that helps.

RE: Masters of printing TPU - what's happening?

You might also have a gap between the extruder tube and the hot end nozel causing larger globs to form in the hot end that cool and make it hard for the printer to push the filiment through.

One way to check this is when cool can you remove the filiment at all or when you remove the filimet while hot end is still olhot but just starting to cool after a print is the end of the filiment that was closest to the hot end larger at the tip than the 1.75 mm filiment? I'd there is a larger mass on the end of the filiment then a gap between your tube and nozel is likely the issue. And there are videos on how to fix that.

Or the tube has deformed and is restricting flow by causing excess friction and removing the tube and inspecting is how you diagnose that. It will be burnt or melted.

Hope these help. Also as mentioned in another reply lower temps like 200c have worked best for me. And like 30 to 40 speeds. Higher temps and obstructed extrusion have made my prints look like the ones pictured.

RE: Masters of printing TPU - what's happening?

Tpu will be more sensitive to even slightly more friction in the tube and hot ends. Because it is flexible when it is obstructed it will compress and not force it's way through the hot end like petg or pla will. if you are getting any "dust" or shavings around the extruder after a long pla or petg print it might be an obstruction. I have spent a decent amount of time troubleshooting these issues. Where it will print pla but not tpu. And sometimes I'll get things dialed and can print tpu and pla with no issues then print petg or abs at higher temps then when I switch back to tpu or petg I'll start having issues again. And it's the extruder tube that deforms and increases the friction and I have to replace the tube even if visually it looks good. Then things start working again. The picture is an extreme example but one of the first I found it's not very clear bit the black bit on the end is where it was in the hot end of the printer and melted.