PETG printing issues

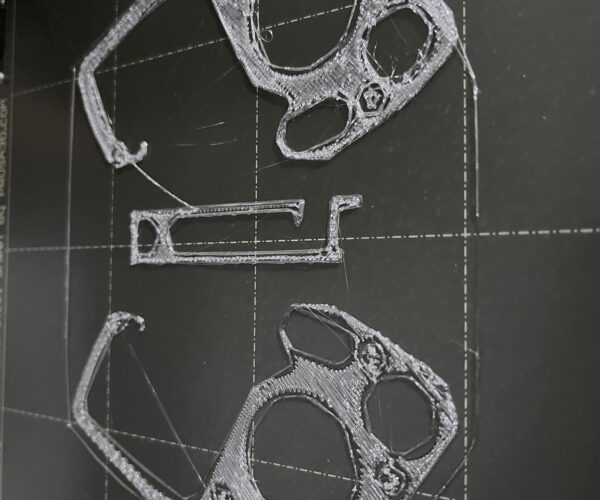

I've been enjoying printing with my self-assembled Prusa. Recently I decided to try some prints with PETG and ordered the material from Prusa. However, I'm getting issues with stringing and very imprecise print results. I thought if I attach a photo some of the experts here could straight away tell if it's an issue with temperature, fan speed, etc. Any help is appreciated! Best, Jan

RE: PETG printing issues

Problems with stringing PETG - > dry your filament

Perform a first layer calibration until the little square at the end of the print is really tight, even and closed.

For eliminating the gaps between infill and perimeters try the procedure described here.

RE: PETG printing issues

Many thanks for the quick reply! The first layer calibration is done correctly, so the issue must be in relation with the material collecting moisture.

I now get the stringing also when returning to the PLA. In your experience is it enough to place the filament roll with silica beads in an airtight bag? Or do I have to bake it in the oven?

RE: PETG printing issues

Drying filament just with the desiccant takes some time. Drying in the oven is much faster. But you should check first that your oven does not get too hot for PLA. And it is perhaps not very advisable to use an oven for food and filament. Get a food dryer, they are not expensive. There are some examples for this here in the forum. Also check out the YouTube channel of CNC Kitchen. He has some good videos on the subject.

RE: PETG printing issues

Looking at your picture it appears to me that your first layer height is too high. You're not getting the filament to "squish" down on the build plate. You might want to try re-running that routine.

Alternatively, this approach has also been instrumental in getting good first layer heights and Z-adjustments. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Aaron

RE: PETG printing issues

Looking at your picture it appears to me that your first layer height is too high. You're not getting the filament to "squish" down on the build plate. You might want to try re-running that routine.

Alternatively, this approach has also been instrumental in getting good first layer heights and Z-adjustments. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

I agreed with this one. My first react when I saw the picture that it needs calibration.

RE: PETG printing issues

Thank you all for your quick feedback with my problem - this is super helpful for a newcomer to 3d printing! I'll try to recalibrate using the method suggested, and I also have a freshly wrapped spool of PETG that I will use to check how much the humidity affected the stringing. Will report back with my findings! One last question: do you re-calibrate every time you change filament, or note down the values when you found the perfect settings for a spool?

RE: PETG printing issues

Thank you for the advice! I'll do some further research on the YT channel.

Do you also have experiences with filament dryer boxes?

RE: PETG printing issues

I have one of the Sunlu S1 boxes where I have added a fan, moved the temp-sensor away from the heat plate and added a thermo-switch that starts the fan at 40 °C. The air circulation makes the box more effective. I also have an Eibos Cyclopes dryer which can take two spools and has a built-in fan. The Sunlu has the disadvantage that the humid air cannot escape from the box and you need to wedge something small under the hood, 3-5 mm is enough. You can see the effect on a hygrometer, the value drops almost immediately, the temperature stays stable, no big drop there. On the Eibos the humid air can escape through the existing holes in the top of the hood. I put bluetooth hygrometers in the boxes so I can monitor this remotely, xiaomi makes some inexpensive ones.

RE: PETG printing issues

Thank you all for your quick feedback with my problem - this is super helpful for a newcomer to 3d printing! I'll try to recalibrate using the method suggested, and I also have a freshly wrapped spool of PETG that I will use to check how much the humidity affected the stringing. Will report back with my findings! One last question: do you re-calibrate every time you change filament, or note down the values when you found the perfect settings for a spool?

No need to recalibrate every time you change spool. But do run calibrate when you change different type of steel sheet and when print go wonky. The steel sheet have different thickness - for an example: smooth steel sheet is thicker than texture and satin sheet. That why you need to run calibration.

I've heard some people run calibrate once every month (depends on how much they run prints). I haven't run calibration after lot of prints on single steel sheet.

RE: PETG printing issues

The printer has memory slots for each sheet type in the firmware. When you do a first layer calibration the value for the selected sheet type is stored. They have different thickness. Before you print, you have to check if the correct sheet type is selected (smooth, textured, satin). If you select the wrong sheet type for your print, you probably will run into problems.