Upgrading my Mini for precision and technical materials

Hey everyone,

I thought I'd start a thread here on what I'm trying to accomplish with my mini and looking to the community for advice on how to get there. (And, before you say "get another printer", I am. I am working on a Voron Trident build and I have a Prusa XL with 5 extruders on pre-order, but that's a whole different story. But leave it to be said, I'm willing to get my hands very dirty.)

I've already upgraded to the Bondtech IFS gearbox and I've built an enclosure. I'm in the middle of upgrading my Mini to the Mosquito hot-end courtesy of the collaborative efforts here. (Just waiting on the PC filament I want to print it in.) I already have an enclosure built and running (and I'm getting good low-warp prints in PETG finally that retain mechanical function close to the bed.) I'm trying to source a good ~24 in (~600mm) sq concrete block to act as a pedestal / mass isolator to reduce ringing (and noise).

I'm planning to reprint all my plastic parts in PC (3DXTech ezPC because I couldn't lay hands on Prusament PC Blend) once the spool arrives.

Once the Trident is up and running, my goal is to make my mini my high accuracy small, fine parts machine. (Thinks gears, mechanisms, small struts, etc printed in ABS/ASA, PC and maybe CF blends.) I'll mostly have it running with an 0.2mm nozzle running at 0.1mm and finer layer heights.

I've heard Klipper / Mainsail can improve accuracy and performance by way of software, and I already have an Raspi 4B driving the printer with Octoprint.

I'd love to figure out how to get it to print very high accuracy and, ideally, faster.

I'd love suggestions and input on these goals.

Anyone have thoughts?

RE: Upgrading my Mini for precision and technical materials

For the concrete paver, a 16" one is plenty big enough. I have room for the printer and spool holder on it. Also, remember to get the rubber paver to go under the concrete one. I'm in the US and got mine at Lowes. Any other big box home improvement store should have the same kind of thing.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE:

Oh, yes, a 16" would fit the Mini just fine. But I want my enclosure to fit on top of it as well. Its dimensions are more like 17"x21" (410mm x 530mm IIRC, I'd have to check my notes.), hence wanting a 24" paver. (I have a local source, I just have to go buy them.)

RE:

Will putting the whole enclosure on the paver limit the benefit of the paver/rubber?

I'm just wondering if noise and vibration will still be an issue this way.

I don't know the answer but am interested to hear thoughts either way.

RE: Upgrading my Mini for precision and technical materials

For the concrete paver, a 16" one is plenty big enough. I have room for the printer and spool holder on it. Also, remember to get the rubber paver to go under the concrete one. I'm in the US and got mine at Lowes. Any other big box home improvement store should have the same kind of thing.

Same here. So much quieter too

RE: Upgrading my Mini for precision and technical materials

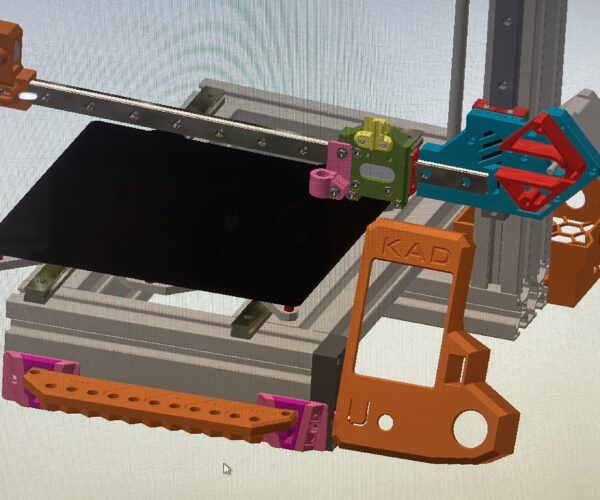

So this is what it looks like roughly right now. (Picture is a few days old, I've only tidied some since then)

The Mosquito is in and printing nicely. The stone and enclosure combined kill almost all noise and work very well in tandem. (I am planning to clad all the shelves in stone, it came out so nicely.)

Klipper and reprint in PC is next.

RE: Upgrading my Mini for precision and technical materials

Will putting the whole enclosure on the paver limit the benefit of the paver/rubber?

I'm just wondering if noise and vibration will still be an issue this way.

I don't know the answer but am interested to hear thoughts either way.

I don't know. I'll be able to comment on that shortly. I have all my spares printed up just in case, and the first spools of ABS just showed up, so I'm going to be starting printing Trident parts in the next day. I'll have the box the Mini came in over it with it on the paver.

I doubt it will make much difference, and I really won't be bothered if it makes some more noise since the printer is getting moved to a different room far away from where I sit all day (or anyone else spends a lot of time).

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: Upgrading my Mini for precision and technical materials

I recently printed some new feet for the mini, found on this very website. They made the printer substantially quieter with the fan now the main noise source. They made about the same reduction in noise that a paving stone did. For those with a “she who must be obeyed” issue it is a great, non obtrusive upgrade.

RE: Upgrading my Mini for precision and technical materials

I recently printed some new feet for the mini, found on this very website. They made the printer substantially quieter with the fan now the main noise source. They made about the same reduction in noise that a paving stone did. For those with a “she who must be obeyed” issue it is a great, non obtrusive upgrade.

Which feet did you use?

RE: Upgrading my Mini for precision and technical materials

I currently use these - https://www.prusaprinters.org/prints/115926-anti-vibration-feet-for-prusa-i3-mk3-mk3s-mk3s-pru

I also tried these but found the printer was slightly wobbly with them - https://www.prusaprinters.org/prints/56850-prusa-mini-anti-vibration-feet/files which could be down to how level my Ikea cabinet is.

I recently printed some new feet for the mini, found on this very website. They made the printer substantially quieter with the fan now the main noise source. They made about the same reduction in noise that a paving stone did. For those with a “she who must be obeyed” issue it is a great, non obtrusive upgrade.

Which feet did you use?

RE: Upgrading my Mini for precision and technical materials

This seems to me as an exercise in diminishing marginal returns. The Mini is a fine little printer, but it's a gantry style printer, it'll never provide the same level of precision as a dual serveo Z axis printer. Weight of the print head is much more an issue on gantry style printers, and while I'm sure Prusa made a number of compromises with the Mini to mate a level of precision to a price point, it seems to me it can get spendy to improve something that by it's design has built in limits.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Upgrading my Mini for precision and technical materials

I currently use these - https://www.prusaprinters.org/prints/115926-anti-vibration-feet-for-prusa-i3-mk3-mk3s-mk3s-pru

I have tried those as well albeit on a Mk3S. I don't know, they didn't come close to what the paver gives me. May depend on the resonator they're on.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Upgrading my Mini for precision and technical materials

Well, I moved the printer and started with the box yesterday. The printer is for now on a folding table and has the paver under it. Even with the box, it was still as silent as you could expect. What surprised me is there is no resonance or moving at all of the table. I spent a while working at the table, and there was no effect on it with the printer running.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: Upgrading my Mini for precision and technical materials

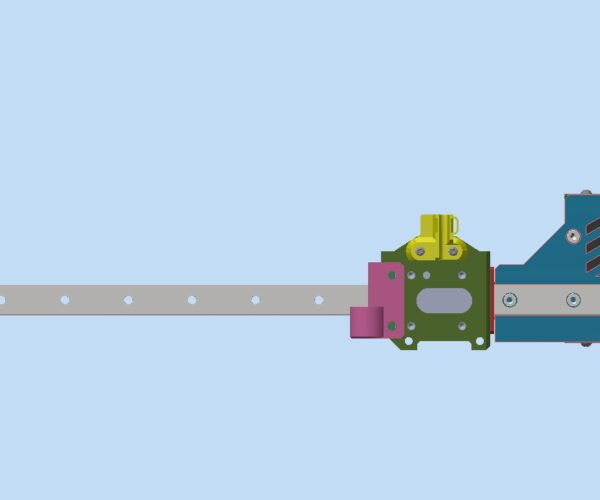

I have linear rails on slow boat from china ( MGN12C for Y, MGN12H for X and MGN15H for Z axe), Plated copper block and nozzle, Mellow NF Zone V6/CR10 heat sink and titan extruder.

Thinking to completly redesign printer and use 30x60 extrudions to get solid build.

what I gound on mini is that fans are hard to get, specially since mini uses 5V ones.

RE:

A bit late, but why not go for the Mini Bear?

Has been done by quite a few Mini owners already (including me)

RE: Upgrading my Mini for precision and technical materials

I don’t like it. Also my will have so many different upgrades, like cooling print, mods on controler board,…

A bit late, but why not go for the Mini Bear?

Has been done by quite a few Mini owners already (including me)