RE: Revo Micro installation on my Mini+

Lengthen the bowden, In my opinion that is the one bit of the guide they have totally wrong, it in no way should say cut the tube shorter since it causes that pressure and squeak which cannot be good for the long term health of that connector.

I had a fantastic week with my revo micro, unfortunately the thermistor developed a fault on Friday but good news is that a replacement kit is shipping to me today.

I've been hunting online for a small olive to make the extruder side connection with a longer piece of PTFE tubing, I'm not sure I can trust anything I've found so far, since it seems to be plumbing related.

Does anyone have a good online source of little compression olives that fit the Mini's Bowden tube? (Asking a lot - but UK supply needed)

RE: Revo Micro installation on my Mini+

Only place I could get them was wedge 3d, had to get the prusa mini spares pack for a tenner and they include a couple in that, I didn't mind getting more spare screws, etc as I'm constantly dropping them.

RE: Revo Micro installation on my Mini+

Sorry, I only know a german supplier.

RE:

Out of stock right now.

Many thanks for the pointer to wedge 3d - looks like a good source for UK printers.

RE: Revo Micro installation on my Mini+

Yeah all my dealing s with Wedge have been positive, even when things have gone wrong.

RE: Revo Micro installation on my Mini+

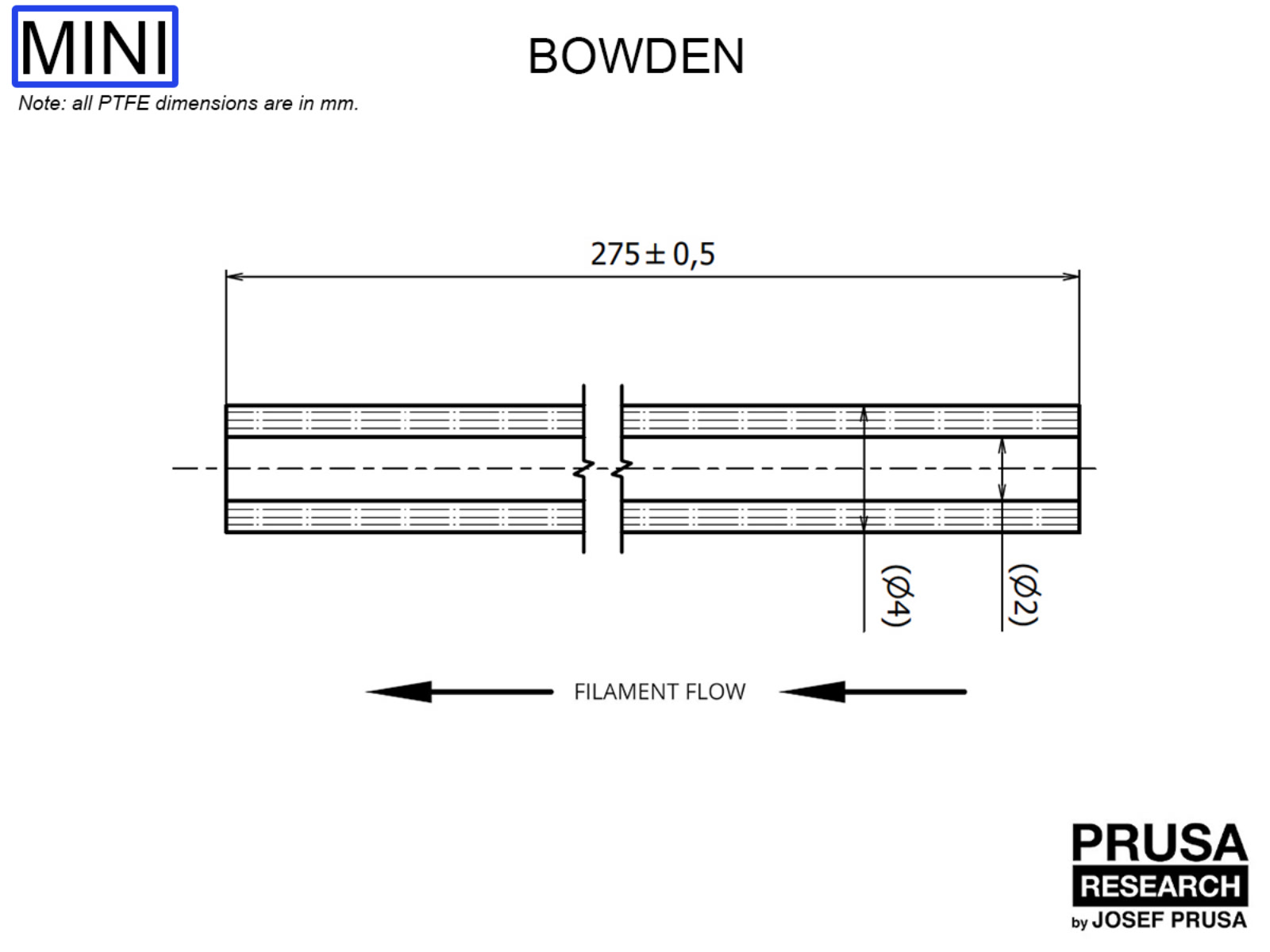

I'm about to install my Revo Micro, and was wondering if someone knows the total length of the Bowden tube should be? I am using a one-piece Bowden right now with pass-through fitting on both the Bondtech extruder and to the top of the stock hot end. I see that the official upgrade guide says to cut the stock PTFE tube close to the olive on the hot-end side but there isn't an exact figure.

Thanks

RE: Revo Micro installation on my Mini+

RE:

Thank you for quick reply. Total length of Bowden on my Mini+ now is one continuous tube of 320.3mm (the 275mm that's visible between extruder and top of hot end + 35.3mm inside the Bondtech heat break + 10mm inside the Bondtech extruder just after the extruding gears to brass fitting).

So am I correct to assume that the PTFE tube in the stock or Bondtech heat break should be subtracted? since the Revo Micro with the integrated heat break.

New total length should be 285mm (275mm visible + 10mm inside the extruder)? Sorry I just need to have someone else check to make sure my logic is ok.

Thanks

RE: Revo Micro installation on my Mini+

I have been thinking about the Bowden tube length. Cutting it is definitely not a good idea. I did this and when I load filament I get a dreadful sound of skipping and grinding in the extruder. And that makes sense; the mini expects to need to feed a certain amount of filament until it gets to the hot end. By shortening the tube, the filament reaches the hot end sooner than expected.

However, I did some more measurements. If I stick a piece of filament in the old hot-end as far as it can go, it goes in 50mm. This is measured to the top of the threading of the brass nut. The ptfe tube goes in about 7mm into the threading so that leaves 43mm of filament to feed from the end of the PTFE tube.

In the Revo Micro, filament goes in 35mm measured to the top. PTFE tube goes in 15mm, leaving 20mm of filament to feed from the end of the tube.

The original Bowden tube is supposed to be 275mm long, but shouldn't a tube for the Revo Micro now be an extra 23mm longer to compensate for the difference of hot-end length?

RE: Revo Micro installation on my Mini+

Not sure why you all cut your bowden tubes. I already offered you a solution:

RE: Revo Micro installation on my Mini+

I cant see why this is simpler than just calculating the length needed?

For this, you still need an extra bit of PTFE. Is the issue the availability of the olives? Is there a reason not to trust the e3d method of attaching the Bowden tube, because I quite like the tool-free method?

@joestinman I think your calculations look sound to me.

RE: Revo Micro installation on my Mini+

I have been thinking about the Bowden tube length. Cutting it is definitely not a good idea. I did this and when I load filament I get a dreadful sound of skipping and grinding in the extruder. And that makes sense; the mini expects to need to feed a certain amount of filament until it gets to the hot end. By shortening the tube, the filament reaches the hot end sooner than expected.

However, I did some more measurements. If I stick a piece of filament in the old hot-end as far as it can go, it goes in 50mm. This is measured to the top of the threading of the brass nut. The ptfe tube goes in about 7mm into the threading so that leaves 43mm of filament to feed from the end of the PTFE tube.

In the Revo Micro, filament goes in 35mm measured to the top. PTFE tube goes in 15mm, leaving 20mm of filament to feed from the end of the tube.

The original Bowden tube is supposed to be 275mm long, but shouldn't a tube for the Revo Micro now be an extra 23mm longer to compensate for the difference of hot-end length?

Well, I went for it. I made a piece of 298mm Bowden tube and used one of my spare olives to attach it.

And I actually think I might have been a tad to conservative. No more grinding and skipping when loading filament, but there still seems to be a little too much force when first filament is purged. Definitely much better though. Maybe someone can verify my measurements?

RE: Revo Micro installation on my Mini+

Would be happy to do this by a bit of trial and error, but those olives are like hens teeth. Unless anyone knows of a Uk supplier!

RE: Revo Micro installation on my Mini+

Not sure if they deliver in the uk, but these look like the right ones: https://www.pneuparts.com/en/item/CRBSC4MS . I will order some.

RE: Revo Micro installation on my Mini+

Yeah, 20€ for delivery, no thanks!

RE: Revo Micro installation on my Mini+

I think it might be these, but more reasonable with £4.95 delivery

https://uk.rs-online.com/web/p/brass-pipe-fittings/2936721

RE: Revo Micro installation on my Mini+

I think it might be these, but more reasonable with £4.95 delivery

https://uk.rs-online.com/web/p/brass-pipe-fittings/2936721

Even for me delivery with Pneuparts was 12 euros. I ordered them from RS. I still have enough spare PTFE to see if I can find the best length necessary.

Are the REVO supplied files for the needed mount flawed?

I am attempting to print the file(s) at this link: https://www.prusaprinters.org/prints/117149-revo-micro-prusa-mini-upgrade/files

The part is needed to mount the new E3D Revo Micro hotend on the Prusa Mini. Despite the names attached to the files, neither the .gcode nor the .stl files that supposedly contain "pre-added supports" actually have those supports in the code. Apparently, the only way to print this part with the (needed) supports is to load (either) .stl file into Prusaslicer and tick the box for "Generate Support Material", then slice as usual. I can't view the .gcode files directly. The .stl model files (with and without the supports) have different file sizes but look the same in the slicer, i.e., no supports are shown. Am I missing something in the instructions? Has no one else noticed or commented on this discrepancy? Will correct/updated files be posted by E3D to replace these apparently flawed ones?

Will/are similar files (be) available to mount the Revo hotend on the MK3 series of machines?

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE:

Despite the names attached to the files, neither the .gcode nor the .stl files that supposedly contain "pre-added supports" actually have those supports in the code. ... Will correct/updated files be posted by E3D to replace these apparently flawed ones?

They use minimal modelled support. Feature detect will not show them as supports but as part of the model. The files are totally fine. There is one support from the build plate to the back of the part and one between the mounting points of the cable guide. More is not necessary.

Will/are similar files (be) available to mount the Revo hotend on the MK3 series of machines?

There is no need for custom files for the i3. The Revo Six uses exactly the same geometry as the V6 in your printer. You can just replace the V6 with the Revo Six. (See here)