Why gap fill is used where it shouldn't be used

Hello,

i have a question regarding gap fill.

There is a model with the wall thickness of exactly 3 mm. My nozzle diameter is 0.4 mm. I have manually set the Extrusion width (all of them) to 0.5. The number of perimeters is set to 3.

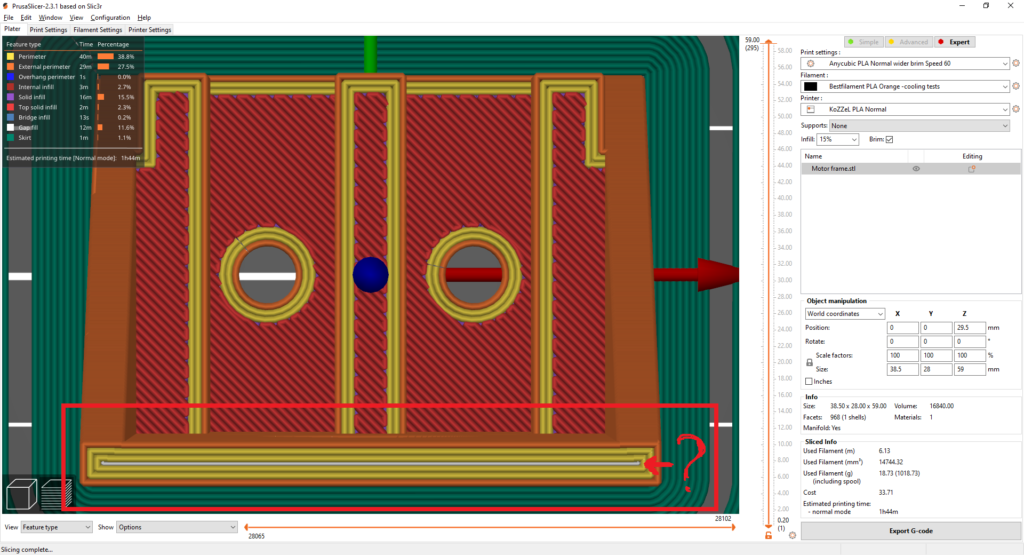

In my understanding, this should give me the wall of 6 perimeters and no gaps. But slicer creates wall of 6 perimeters and a gap between them as on this screenshot:

If i set Extrusion width to 0.55 there is no gap, but 0.55 is too high value for my nozzle.

RE: Why gap fill is used where it shouldn't be used

Walls in PrusaSlicer are not an exact multiple of your perimeter width thick. This is due to the math used to calculate extrusion centerlines that PrusaSlicer inherited from Slic3r.

The exact spacing between perimeter extrusions is based on both extrusion width and layer height. This is done to improve the stability of vertical surfaces.

The tooltip for the extrusion multiplier setting in PrusaSlicer provides a hint, but I and others stumbled around a bit before realizing the importance of the Slic3r flow math.

If you are after high precision, calculate your extrusion multiplier using the widths calculated using the Slic3r flow math. I’ve created a spreadsheet that (I think) takes all the factors into account.

If you want to keep life simple, the “add perimeters” math will get you close and a 2nd print and measurement is usually plenty accurate enough to get a good extrusion multiplier value.

If you want to stay sane, generate your test prints with another slicer. (I think.)

RE: Why gap fill is used where it shouldn't be used

FYI - If you're using quality nozzles, you can use extrusion widths up to approximately 200% of your nozzle size without problems. Below 120% is a safe value.

RE: Why gap fill is used where it shouldn't be used

@bobstro

Thanks! This is really helpful. I really did not understand that the math here is much more complex than simply sum of the line widths.

Now it makes much more sense.