Seam gaps in bigger nozzles

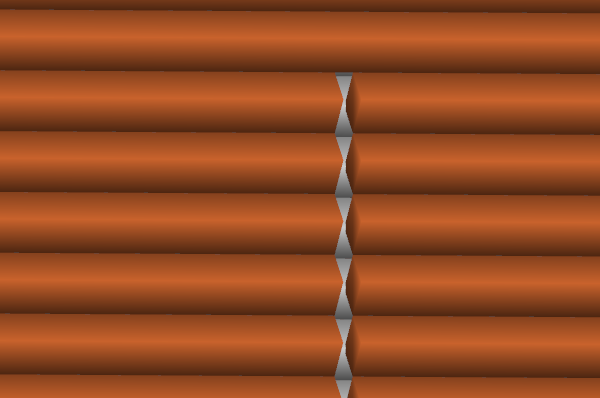

I have a .6 nozzle and PrusaSlicer always slices with a big gap at the layer change:

It's big enough that it is clearly visible in the print:

I've tried everything, but i can't seem to get rid of this. Retraction, wipe, overlaps, layer changes, flow rate, pressure advance, etc.

Googling a bit, there seems to be a lot of people having this when changing to bigger nozzles, but I can't work out what it could be.

I assume it's trying to avoid blobs at layer change, but it seems it's too enthusiastic.

If anyone has any idea, I'd be extremely thankfull.

RE: Seam gaps in bigger nozzles

AFAIK it's normal to see this gap in the slicer and it does not indicate that there is actually a gap that's going to be voluntarily printed. It's so that you can see the seam position in the preview. It's more visible with larger nozzle sizes, but you can still see it with smaller nozzle sizes if you zoom in far enough.

I don't think it's possible to ever get rid of the z-seam entirely, although in your picture it is indeed quite visible. In addition to fine-tuning things to reduce the visibility of the seam you might also want to play with the seam position setting / seam painting feature to put in in a less conspicuous place.

According to the Prusa KB, the extrusion multiplier and linear advance are the things that affect this most. On my MINI+ the linear advance is not configurable (I think) but it might be on the MK3 series or whatever printer you might have.

Before messing with linear advance though, I'd try calibrating my filament with a procedure such as this one (says "stringing" in the title but it covers more than that, as the intro enumerates), rather than fiddling with values blindly trying to get better results. I don't know if you tried a procedure like this before or you went with the "trial and error" approach, but that link might be a good start in any case:

Another good resource to fine-tune extrusion multiplier:

https://teachingtechyt.github.io/calibration.html#flow

I'm not an expert but that's what I'd try first! Let me know how it goes.

RE: Seam gaps in bigger nozzles

I have the same "problem" with my Voron2.4 and a 0.8mm nozzle...

@gus Have you found a solution?

RE: Seam gaps in bigger nozzles

Have you tried telling a little fib to prusaslicer.

Just say your nozzle is smaller.

for example :

i have a 0.6 nozzle , but i tell prusa in the printer settings i have a 0.35 "nozzle diameter" (or as low as you can get depending on layer height an extrusion width)

And i force the "default the extrusion width" and "first layer" parameters in print settings to 0.7 mm width. to keep the correct width i wanted.

This seems to get an nearly identical slice but with a much tighter seam.

RE:

Hmmm, interesting...

I'll try this workaround

RE: Seam gaps in bigger nozzles

I also had this issue printing PETG with a .6 nozzle on my MK3S. I edited the start Gcode in the filament settings. for the .6 nozzle for the linear advance. I changed the K value to 0.028

M900 K{if printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.6}0.12{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.8}0.06{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/}0.2{elsif nozzle_diameter[0]==0.8}0.02{elsif nozzle_diameter[0]==0.6}0.028{else}0.08{endif} ; Filament gcode LA 1.5{if printer_notes=~/.*PRINTER_MODEL_MINI.*/};{elsif printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}M900 K200{elsif nozzle_diameter[0]==0.6}M900 K24{elsif nozzle_diameter[0]==0.8};{else}M900 K45{endif} ; Filament gcode LA 1.0

RE:

Was there ever a solution to this? I have the exact same thing since I switched to a .6mm nozzle.

RE: Seam gaps in bigger nozzles

Disabled external perimeters first and the issue went away for me! I tried a good 50+ test prints going through every setting I could think of. Print quality got better but the seam issue never went away until I disabled printing external perimeters first.

RE:

The issue never did go away. It was just hidden a bit more when I disabled external perimeters first. After weeks of testing and many dozens of test prints later I did eventually find the issue. It was the Arachne perimeter generator. I switched it to classic and got perfect prints instantly. I'm super confused why arcane does such a poor job and is the default setting. It prints much faster but has huge issues with the larger nozzle. Classic takes longer but produces night and day better results.

RE:

I can't thank you enough for your post! You saved me a lot of time and helped me retain my sanity.

I have been reslicing my models to take advantage of the latest performance and speed advancements offered in PrusaSlicer 2.6.1 with my MK4's using 0.4mm nozzles. While the print speeds have been welcome, I began noticing significant gaps in 2.0mm walls where seams were present, either system generated or those I painted in. As soon as I read your post I switched from Arachne to Classic mode and the seam gaps disappeared!

Thank you again!

RE: Seam gaps in bigger nozzles

Thanks! using 0.8mm nozzles for XL in prusaslicer, and this solved it.