Thin first layer when printing support material

Hello!

I recently got back into 3D printing after a 3-year break

So far i had decent success printing things on my old-ish CR10-S, as long as no support material is needed

For some reason, support material will always print extremely thin first layers on the bed, resulting in them instantly failing due to the thin string not sticking to the bed

Is there a setting i am missing thats causing support material/rafts to extrude thinner?

Best Answer by Neophyl:

ok, those last 2 pics are definitely a case of your nozzle is too high above the bed. Theres zero squishing of the filament to the print bed. The cr10 range is terrible for needing constant adjustment. I have one, and before I fitted a steel sheet attached with magnets similar to what the Mk3 uses I had to constantly tweak it. Now as the bed comes off to remove the parts I have to do that much less. Its a side effect of having things on springs. Also don't forget that you have to have the bed heated and soaked to temperature before adjusting it if you want repeatability.

As for the settings in the project. Theres a few things I noticed that could be changed. Not sure if they will help in the long run so I'd test each individually.

First under Printer Settings > Machine Limits you have the dropdown set to Emit to gcode. The default for the cr10s is USe for time estimate I think. By setting it then you are over riding the printers firmware limts with the ones from PS. Thats ok if they are set up correctly and thats what you want to do.

Your first layer height is a bit low if you are having adhesion issues, set it to 0.2 or even 0.25.

Rafts. A raft is not going to make any difference to a print with a flat bottom, except to make things worse.

Essentially you need to be printing one of the single layer calibration prints used for bed leveling and getting that sorted out 100% before trying to print anything.

RE: Thin first layer when printing support material

A picture of what you mean would help but do you mean the bottom support interface layer that is a thin back and forth zig zag ?

If so then in PS2.3.x theres nothing you can do about it. However I have a cr10s as well as a prusa mk3 and on that with a pei print surface I had no trouble with them sticking once the bed is leveled correctly and the gap is correct. Just like leveling and the z height is so critical on the prusa. You have to have the basics dialed in first. The extrusion width for support in PS is set to be slightly less in most default profiles too. That is normal. For a 0.4mm nozzle the default for normal perimeters is 0.42-0.45 but for support structures its 0.35.

Saying that though you really really should be using Prusa Slicer 2.4 now.

In PS 2.4 they revamped the support considerably, making it much better. While you still cant stop it doing that layer it now has a setting called first layer density. By default its set to 90% now and it produces a nearly solid first layer that is better at sticking and also means it is removable much easier as it comes away in one part.

Also the new 'snug' support option (not on by default but really should be) is way way better.

RE: Thin first layer when printing support material

Thanks for the fast answer!

I am coming from IdeaMaker, where i am used to the raft being this massive, extremely thick thing that it just slaps to the bed, haha

My issue currently is that it prints fine, unless the first layer is a raft or has support material on it, then it will just make a mess

Attached a zip with my done print from yesterday and a previous attempt where the supports printed first and failed instantly

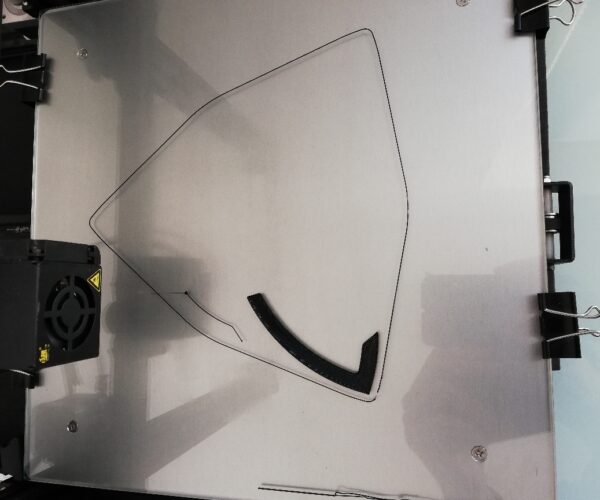

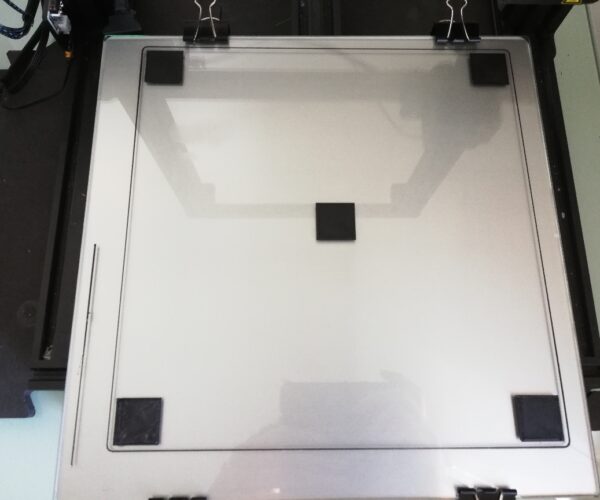

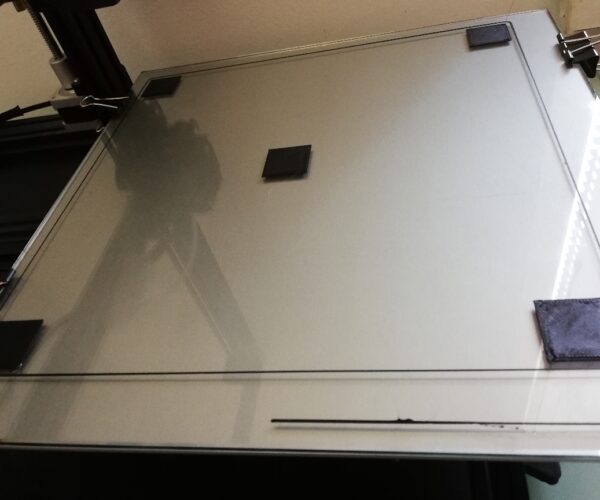

PrinterPics

RE: Thin first layer when printing support material

Sorry to me it just looks like your bed needs adjusting to be closer to the nozzle. If things are sticking then theres 2 fundamentals, is the surface clean and free from all contaminants like skin oils etc and is the surface the correct distance from the nozzle. Once you get those 2 sorted then theres not a problem with even thin single lines sticking.

If your first layer isn't sticking once those are taken care of then you could try changing the extrusion width for the first layer or if your bed is uneven then setting a thicker first layer in the slicer might help to compensate for physical issues.

btw you can attach pictures to posts using the add media button and uploading them to the server and then selecting which ones you want.

RE: Thin first layer when printing support material

Did some experimentation with a file i successfully printed a few days ago, which is that celtic knot that i printed for a friend (the one i sent pictures of in the previous post)

first layer seems fine, not perfect but fine

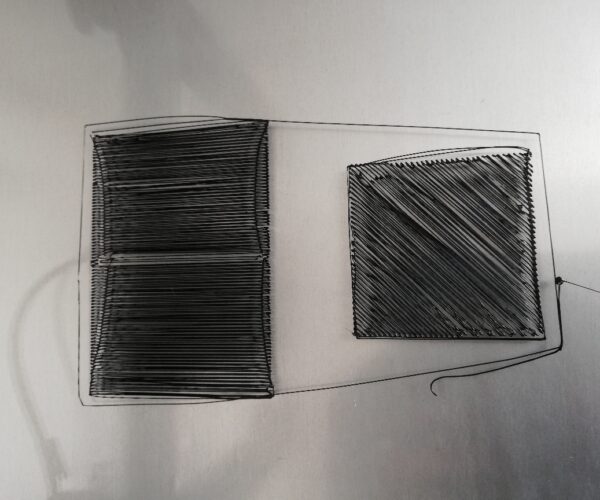

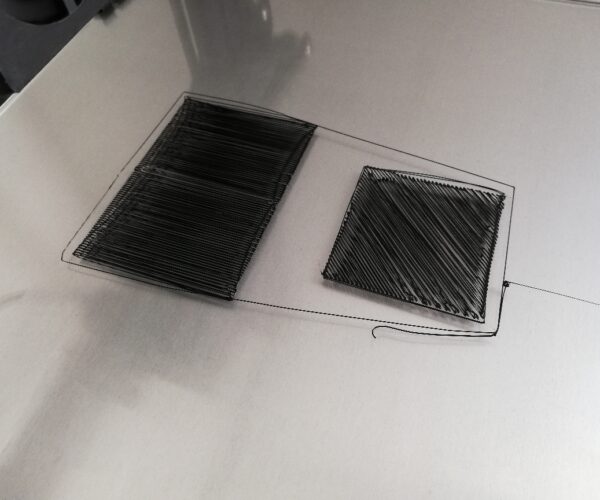

then i just put some cubes into prusa slicer and just told it to print

and somehow between a few days ago and now, i managed to mess up my first layer settings

Was accusing the raft/support material since that knot did not use any supports and the newer print i tried does

any recommendation on printer settings to make it lay down a thicker first layer?

Also thanks again for the help and sorry for being so backwards with all this, i am still very inexperienced

RE: Thin first layer when printing support material

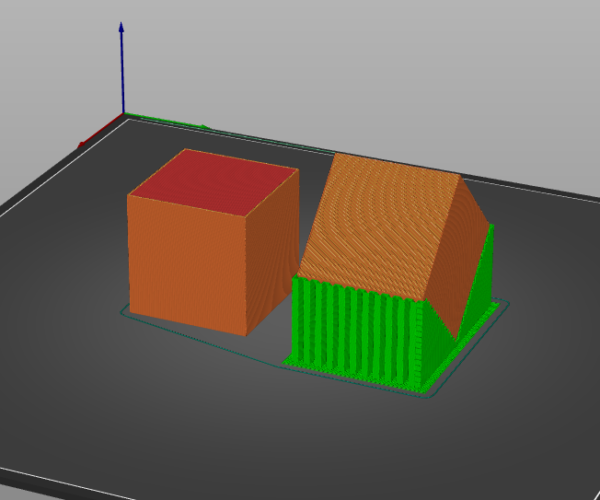

Also have a .3mf file, in case my settings are messed up

really feel like i accidentally broke something simple

RE: Thin first layer when printing support material

ok, those last 2 pics are definitely a case of your nozzle is too high above the bed. Theres zero squishing of the filament to the print bed. The cr10 range is terrible for needing constant adjustment. I have one, and before I fitted a steel sheet attached with magnets similar to what the Mk3 uses I had to constantly tweak it. Now as the bed comes off to remove the parts I have to do that much less. Its a side effect of having things on springs. Also don't forget that you have to have the bed heated and soaked to temperature before adjusting it if you want repeatability.

As for the settings in the project. Theres a few things I noticed that could be changed. Not sure if they will help in the long run so I'd test each individually.

First under Printer Settings > Machine Limits you have the dropdown set to Emit to gcode. The default for the cr10s is USe for time estimate I think. By setting it then you are over riding the printers firmware limts with the ones from PS. Thats ok if they are set up correctly and thats what you want to do.

Your first layer height is a bit low if you are having adhesion issues, set it to 0.2 or even 0.25.

Rafts. A raft is not going to make any difference to a print with a flat bottom, except to make things worse.

Essentially you need to be printing one of the single layer calibration prints used for bed leveling and getting that sorted out 100% before trying to print anything.

RE: Thin first layer when printing support material

all these pictures were taken right after eachother though, maybe 10 minutes apart

the only difference is that the first one where the layers are nicer are slightly older gcode files than the ones that print thin and bad...

will re-level the bed though and give those settings a go

thanks!

RE: Thin first layer when printing support material

Adjusted the first layer width to 200% and also made the first layer taller at 0.25mm

Also raised the print bed a litte (though its a bit too close now in some areas), raising it after homing until a sheet of paper fit snug between nozzle and bed

now it seems to be working pretty well, only need to do some minor adjustments

Thanks a lot for the help!