Slicing Tolerance Issue

Hi,

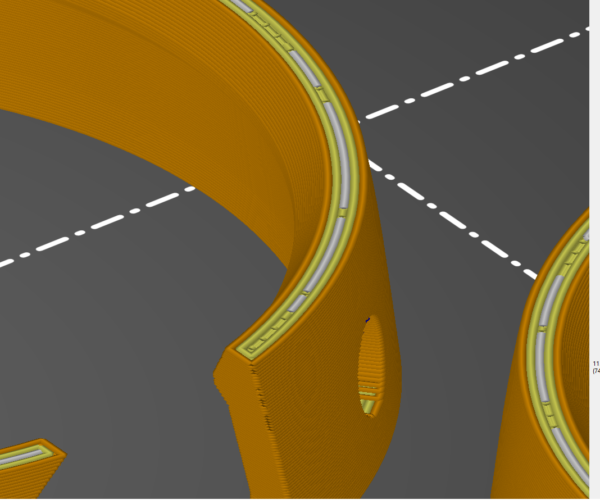

i'm facing an issue slicing a round object. Its actually an issue only because of how it is sliced the parts need quiet some more time due to many more retractions.

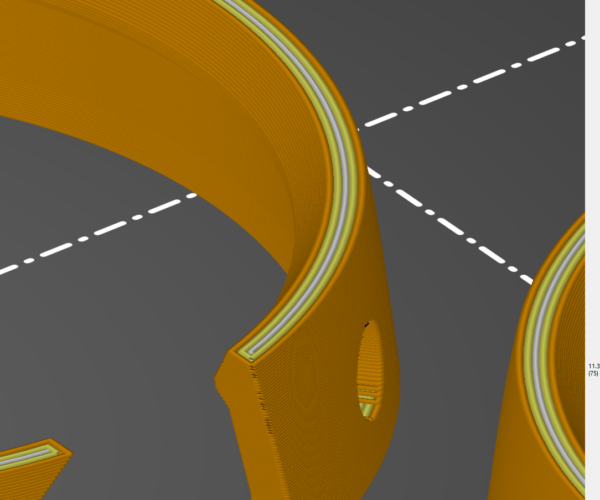

I only see the issue on a few layers. Actually I dont know the reason why it breaks up the print line into several smaller once here as the radius is constant and with the same center for the inner and outer.

My questio is if there is a way to allow some tolerance in slicing to avoid these small steps?

Here some screenshots before the layer with the issue and after:

Thanks for support!

RE: Slicing Tolerance Issue

What you think is round isn’t, it’s broken up in a series of triangles, stl’s all are. When you have an inner perimeter and an outer perimeter the angles where triangles join the ones besides it don’t always line up at the same spots, not to that much mathematical precision anyway. So where the thickness is fractionally smaller in those areas the slicer decides it can’t fit a full perimeter in so it uses a series of perimeter and gap fills. It’s really common on circular structures when sliced with slicer (all the varieties). You can try adjusting the perimeters extrusion widths to get a better fit.