prusa slicing too small

I have the problem that all my prints are too small (couple of sub mm)

I first thought that it is an issue with the printer itself. I said that the x-axis should move to 100 mm from the left and I measured it. And it is 99,99 mm (most likely some tolerances in measuring)

so that is out of the way.

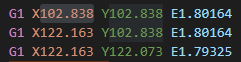

So I tried to look in the end result gcode

I have an object that 20 mm wide but in the gcode the travel distance is 19,325 mm

is there a way to fix that and if yes how?

Go back to your original CAD file and incorporate calibration multipliers. Don't forget that the gcode movement factors in the width of the extrusion and that the limit of accuracy is about half an extrusion width.

If it really matters print oversize and machine to fit.

Cheerio,

RE:

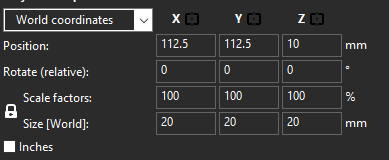

For some software info. I am using prusa slicer 2.6.0 alpha5 but also in 2.5.0 it is the same problem. Even on bare minimum changed print settings it is the same.

I am using a 0,6 mm nozzle (I've set it in the slicer too). Before I changed it, it had the same problem.

cura slicer is much closer for given size/length and actual printed size/length

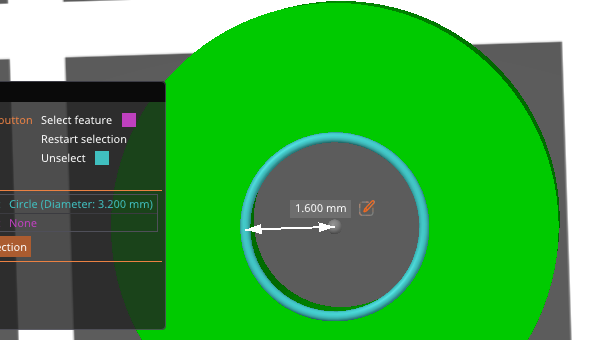

this hole should be 3,2 mm (prusa)

RE:

That's looks right.

Your CAD has defined the deposition line as 3.2mm. It translates to a mesh polygon with points on the circumference but chords between, so closing a little.

Slicer sees chords and a zero thickness line defining the shape which it turns into a gcode path with whatever extrusion thickness you have set.

The printer produces the defined shape.

You measure it. 2.75mm is about right for a 0.45mm extrusion width.

So your original should be calibrated to 3.65mm diameter.

BUT if you want a screw to stay in there it will need something for the thread to bite into.

Cheerio,

RE: prusa slicing too small

I still don't get it. It is a downloaded STL where I don't have access to the cad file(s). And just a regular question. Why are the paths not calculated for the hole to be exactly 3,2 mm thick.

It doesn't make sense to me when I say the hole should be 3,2mm and I get 2,7. That is wrong to my understanding.

You downloaded a mesh, not a hole. That the mesh describes a hole is incidental. The slicer has no way of knowing which aspect of the mesh is critical so it follows the lines of the mesh. The STL format doesn't contain the information which is why industry tends to prefer other formats, eg STEP files which do.

The designer should incorporate the nozzle size/extrusion width into the calculation where it is critical, if you slice the same part for a 0.25mm nozzle it will be noticeably different to the same part sliced for 1mm. This is why the printing notes frequently include nozzle and layer suggestions.

More subtle; The printer is laying down hot plastic. On cooling it will contract. Different plastics, even the same polymer from different manufacturers or with different pigments contract to a different degree. A gcode movement extrudes slightly larger than its path as the filament squishes, then the part will contract as it cools and the final dimension depends on the working temperature... It will even vary according to the direction of the lay as the molecular alignments are altered by the extrusion process.

So for critical parts print a prototype, measure it and calibrate. Where it matters print oversize and machine to fit.

That said, if a hole size is critical, design for it to be a little tight and then ream it to size with a drill or tap.

Cheerio,