Layer seam too big nozzle because travel?

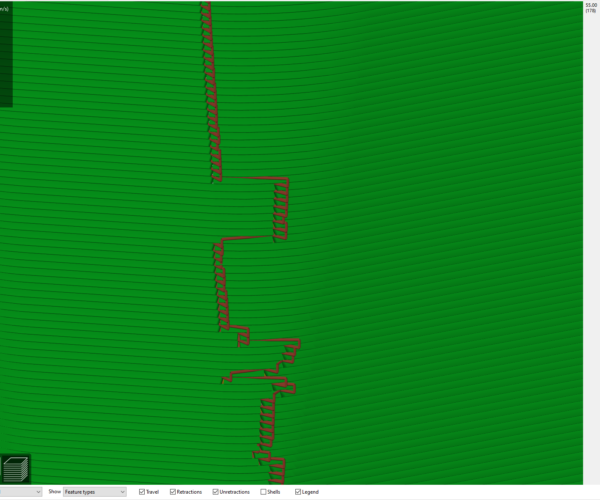

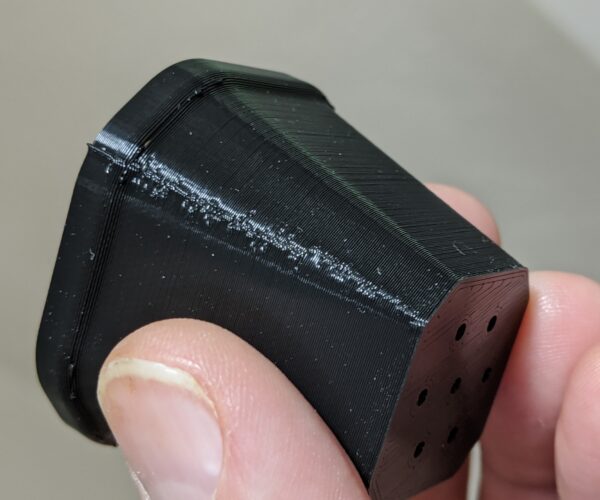

I see weird travel travel lines on layer change, which result in the corresponding big seam on the finished print. The seam is on the outside, the inside looks much better.

The printer also slows down before a layer change needlessly.

I even tried vase mode, and it works much better, but still slows down, but not as much as regular, producing a barely visible seam.

I tried a lot of stuff, changing retraction settings, disabling retraction, disabling wipe on retract, nothing worked.

Any ideas?

RE: Layer seam too big nozzle because travel?

Have you tried the seam placement options? There is one to place the seam in a line to the rear of the object, which may work for you if one side of your finished project will not be as visible as the others.

RE: Layer seam too big nozzle because travel?

Have you tried the seam placement options? There is one to place the seam in a line to the rear of the object, which may work for you if one side of your finished project will not be as visible as the others.

I'm interested in the controlling travel that happens at layer change, not other options that would mask it.

RE: Layer seam too big nozzle because travel?

@is-this-taken-hr

its difficult/impossible to avoid them, but maybe you will find some useful informations on this webpage.

RE: Layer seam too big nozzle because travel?

What settings are you using ? Everyone has seams but that is very very large. I'd call it abnormal. I've only seen them that large with either large nozzle sizes or when the printer is over extruding.

If the part isnt propriety would you be willing to save your project (file > save as) and then zip up the resulting .3mf file and attach it here. Needs to be zipped up or the forum wont accept it. 3mf files save all the settings and the model so allow much easier debugging. I'd like to print it off and see what I get, it doesn't look like too large a model.

RE: Layer seam too big nozzle because travel?

First, I'd like to get the answer to my OP, before we go down the rabbit hole of 3D print debugging.

Is that travel normal?

Can it be avoided?

What settings affect it?

For now, let's assume my printer is perfectly spherical 😉

RE: Layer seam too big nozzle because travel?

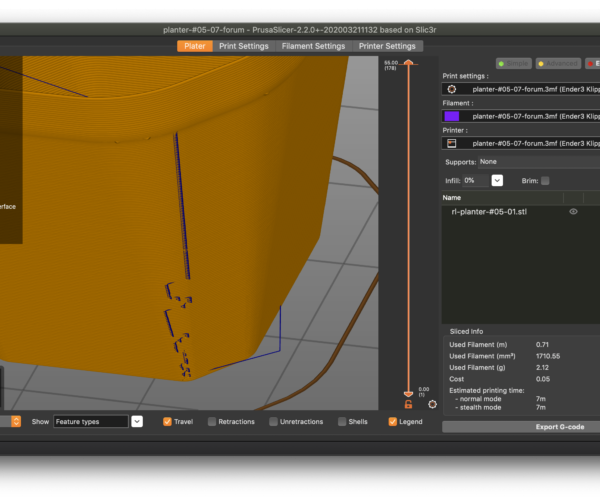

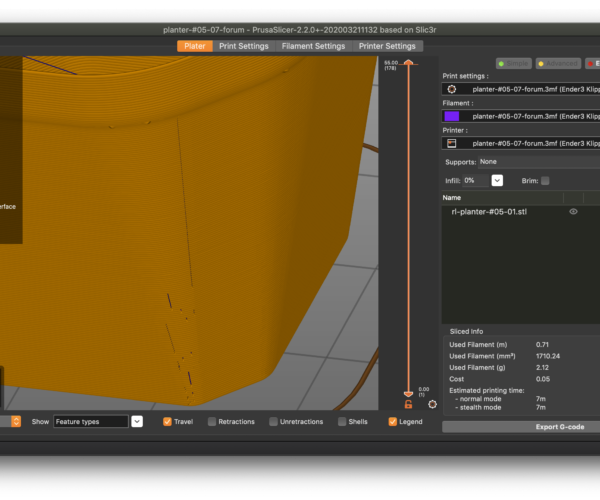

All right, here is the 3mf.

Do you get the perpendicular travel on layer change, you can see it after slicing?

RE: Layer seam too big nozzle because travel?

First of all thanks for the 3mf. It really really does help.

I am not an expert in the inner workings of PS but when I slice with your project I too see the travel outside of the perimeters. I have no idea as yet why its doing so.

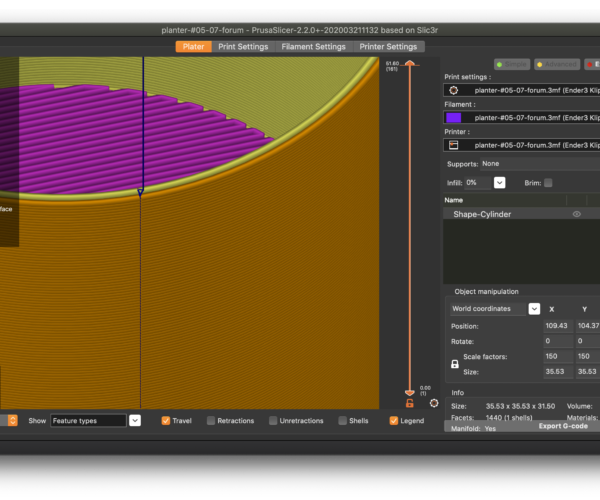

With your current settings its printing an oversized extrusion single perimeter (preview>width = around 0.48 for most of the model). If you turn your perimeter setting to 1 instead of 2 it will still slice as a single perimeter with the same width of approx 0.48mm, however when you do that the weird little travels outside the perimeters stop. Might be one to post over on github about and see if the devs can explain why it does that external travel move.

This model was practically made for vase mode except for those holes in the bottom lol. As that forces it to a single perimeter I'm not surprised it printed better.

You mentioned that it was slowing down even in vase mode ? It shouldn't be, the gcode preview shows a constant speed of around 60mm/s for the perimeters once the bottom is printed when put into vase mode, in fact all the perimeters even on your original settings print at ~60mm/s though. It should print at a constant rate as there are no retracts or anything. Could that be a klipper data throughput issue ? USB is not the fastest transport medium when it comes to realtime high speed comms.

It seems your walls are being throttled to the 60mm/s by the filament cooling settings.

RE: Layer seam too big nozzle because travel?

First of all thanks for the 3mf. It really really does help.

I am not an expert in the inner workings of PS but when I slice with your project I too see the travel outside of the perimeters. I have no idea as yet why its doing so.

With your current settings its printing an oversized extrusion single perimeter (preview>width = around 0.48 for most of the model). If you turn your perimeter setting to 1 instead of 2 it will still slice as a single perimeter with the same width of approx 0.48mm, however when you do that the weird little travels outside the perimeters stop. Might be one to post over on github about and see if the devs can explain why it does that external travel move.

This model was practically made for vase mode except for those holes in the bottom lol. As that forces it to a single perimeter I'm not surprised it printed better.

You mentioned that it was slowing down even in vase mode ? It shouldn't be, the gcode preview shows a constant speed of around 60mm/s for the perimeters once the bottom is printed when put into vase mode, in fact all the perimeters even on your original settings print at ~60mm/s though. It should print at a constant rate as there are no retracts or anything. Could that be a klipper data throughput issue ? USB is not the fastest transport medium when it comes to realtime high speed comms.

It seems your walls are being throttled to the 60mm/s by the filament cooling settings.

Yeah, I'll open an issue on GitHub.

Putting vertical shells to 1 really did change the weird nozzle travels. It printed much better, as expected. Thanks for that one!

Any idea about the glitches around the planter lip? They can be clearly seen in the preview. Without detect thin walls, the whole lip section is bungled. Ah, just figured it out. It's a detect thin walls issue. Solution: disable detect thin walls, lower extrusion width a bit.

First, I really dislike the Slic3r vase mode, both Cura and S3D can handle it much better, the holes print just fine.

As to the slowdowns in vase mode, it seems it an interplay of Klipper and slicers. I'm investigating.

RE: Layer seam too big nozzle because travel?

Yeah thin walls can be a bit problematic. The devs know that too so I'm sure it will be worked on at 'some' point.

You might want to try out Super Slicer https://github.com/supermerill/SuperSlicer/releases . Its a fork of Prusa Slicer, with a lot more options and tweaks. It also handles thin walls differently (and I think better) as well as improvements to gap fill etc (so less issues with wall bulges on changing thicknesses). Its well worth trying and its compatible with PS so all your custom profiles can be exported/imported using config bundles. Basically its far more configurable for the tinkerer 🙂

Its also getting /has got some specific klipper support. iirc thats going to /is a separate flavour in the settings.

RE: Layer seam too big nozzle because travel?

@neophyl

Thanks! I did use some of his builds a long time ago.

The issue with me is lack of time to properly tune everything, which I have to, since this is a custom build printer.

Oh FFS.

I disabled the thin walls, as stated above, but now it prints vertical perimeters twice or two perimeters? Even though it shows only one in the preview. Would you please check, maybe I'm missing something. The file size of the gcode also doubled!

RE: Layer seam too big nozzle because travel?

A few observations based on the 3MF file:

- You seem to be suffering from a bit of over-extrusion. While my z-seam is clearly visible, it is nowhere near as prominent as in your 1st pic.

- If your slicer settings do not perfectly match your physical printer and filament settings, any variation shows up as over or under extrusion. Suggest calibrating your extrusion multiplier for this specific filament. It looks like you may have done this already with your 0.8263 multiplier, but it's worth verifying. Also be sure the filament diameter is set correctly.

- You are using very aggressive speeds (500mm/s), acceleration (9000mm/s) and jerk (10mm/s) settings for XY for your printer settings. Your print settings are also aggressive with 150mm/s perimeter speeds and 200mm/s infill speeds. Your are only using a retraction length of 0.6mm which is low for a typical bowden extruder setup and can contribute to stringing and seam defects. Your retraction speed is 140mm/s which is also very aggressive. On an Ender 3 printer (what's in the profile name), all of these are likely to contribute to visual defects. These may be offset by Klipper settings, but those aren't apparent in the 3MF. No idea what your custom printer hardware is capable of if different.

- Your filament cooling settings are set to slow down if layer print time is below 3 seconds. While this is low, printing this part with a single perimeter does result in layer times below 3 seconds, contributing to slowdown. Given your speeds above, this may not be a bad thing.

I'd try printing slowly to see how things look, then speeding up to see where results drop off. If you can't get good quality printing slowly, there's no sense speeding it all up.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Layer seam too big nozzle because travel?

I'm understanding you're concerned about the moves outside the perimeter made by the slicer at the z-seam, shown here as the little blue moves:

If printing a part with 2 perimeters, the external moves do not occur:

If you slice your part with 1 perimeter set in print settings, they also are not present:

I haven't done a test print with these settings, but the differences are interesting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Layer seam too big nozzle because travel?

A few observations based on the 3MF file:

- You seem to be suffering from a bit of over-extrusion. While my z-seam is clearly visible, it is nowhere near as prominent as in your 1st pic.

- If your slicer settings do not perfectly match your physical printer and filament settings, any variation shows up as over or under extrusion. Suggest calibrating your extrusion multiplier for this specific filament. It looks like you may have done this already with your 0.8263 multiplier, but it's worth verifying. Also be sure the filament diameter is set correctly.

- You are using very aggressive speeds (500mm/s), acceleration (9000mm/s) and jerk (10mm/s) settings for XY for your printer settings. Your print settings are also aggressive with 150mm/s perimeter speeds and 200mm/s infill speeds. Your are only using a retraction length of 0.6mm which is low for a typical bowden extruder setup and can contribute to stringing and seam defects. Your retraction speed is 140mm/s which is also very aggressive. On an Ender 3 printer (what's in the profile name), all of these are likely to contribute to visual defects. These may be offset by Klipper settings, but those aren't apparent in the 3MF. No idea what your custom printer hardware is capable of if different.

- Your filament cooling settings are set to slow down if layer print time is below 3 seconds. While this is low, printing this part with a single perimeter does result in layer times below 3 seconds, contributing to slowdown. Given your speeds above, this may not be a bad thing.

I'd try printing slowly to see how things look, then speeding up to see where results drop off. If you can't get good quality printing slowly, there's no sense speeding it all up.

This is why I did not want to post details about my setup. It's easy to get lost chasing all these. There is no point looking and comparing physical prints if the there is an slicing error, which there clearly was.

@neophyl figured it out, it was the vertical perimeters parameter coupled with the extrusion width.

If set to 2 walls, it will still print 1 wall, but the nozzle will do the weird travel producing the exaggerated seam.

There was also the "detect thin walls" which seems to be complete bollocks.

With regards to your comments, the printer is calibrated and those speeds are fine for my "Ender 3", 32bit SKR board with TMC2208, BMG direct drive V6 hotend with Klipper.

The layer print times are critical, PLA can't handle another layer in less than 4 seconds.

RE: Layer seam too big nozzle because travel?

My initial view when I saw your settings was woah 🙂 then I saw the klipper naming and so ignored the high speeds as I’ve seen similar discussions over on the super slicer github. Makes me want to do something along those lines with my cr10s. Sounds like you have a nice setup.

I also realised that anyone who has modified an Ender to have a different control board and was running klipper wasn’t exactly a newbie so I made the assumption that you would have already calibrated the basics which is why I didn’t make any of the usual suggestions when we see seems like that.

I did wonder why you were printing the walls so ‘slow’ compared to the other speeds but yeah cooling a layer that prints that quickly is always going to be a challenge, so that makes sense.

Anyway glad I could help, it’s what we hang around here for.