Customized slicing on part of the model

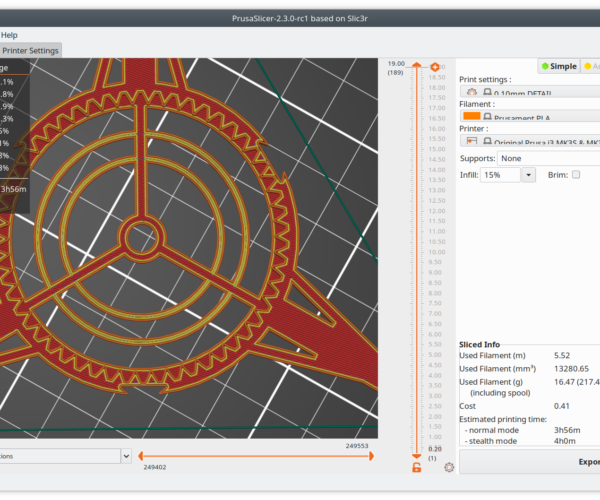

Hi, I'm making some custom planetary gears and under 0.1 or 0.2mm profile the slicer makes zig-zag lines on the 120° beams and the inner circle. This causes the gears to have **extra friction**:

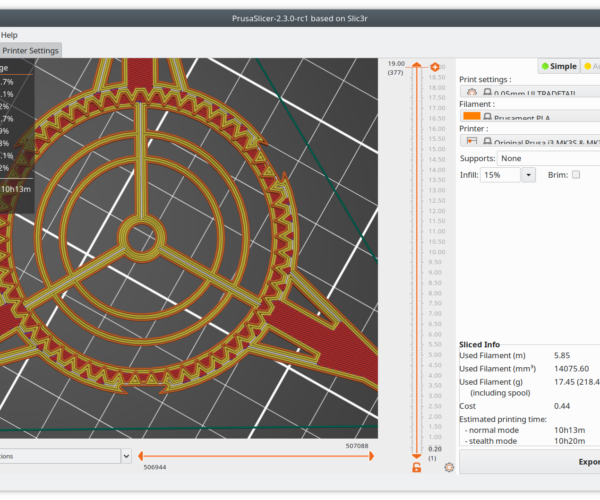

On ultra detail, the lines are much nicer, exactly what I would like to achieve:

However I don't want to have the ultra-detailed print, as it takes way too long. How can I combine the two together? For example, if I just make a circular selection from the ultra-detailed slicing and paste it on the normal slicing?

Thanks!

RE: Customized slicing on part of the model

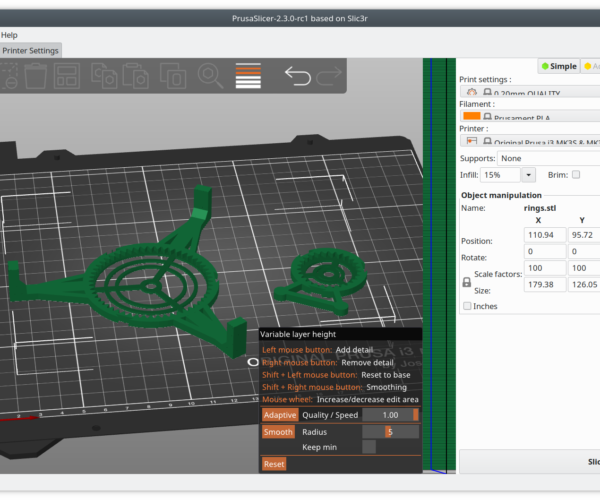

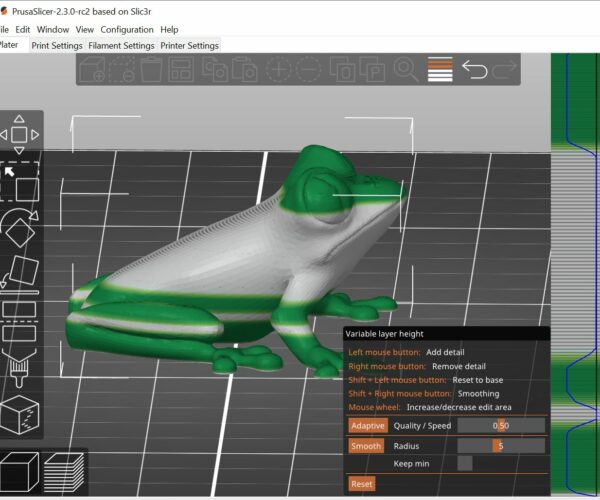

Variable layer height

set the main layer height and then make the bits you want better detained a lower layer height

https://help.prusa3d.com/en/category/prusaslicer_204

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Customized slicing on part of the model

Wow, thanks for a quick reply!

I played around with it a bit, however even if I set the mask to work on all the heights and the highest quality, it still produces the same result -- I would expect that it should give the same slicing as the ultra detail. Do you think it might be due to the size of the print (0.2mm) ? I didn't find how to set variable layer size.

RE: Customized slicing on part of the model

@ms-3

I reduced the layerheight in the areas with rapid curvature changes

As you can see in this picture the reduced layer height changes are visible in the sliced model

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Customized slicing on part of the model

Joan I don't think the issue is layer height. Looking at the OP pictures the difference is the number of perimeters used for the 2 profiles. The first picture is 2 perimeters and infill (the zig zag mentioned) while the second picture has I think 3 perimeters with the resulting reduction in infill needed. If this is the case then just change the number of perimeters on your print profile to whatever works for you.

If you save your project as a 3mf file (File>Save project As) and then take the resulting .3mf file, zip it into an archive and attach it here we can take a look at all the settings you are using. It must be zipped up or the forum wont accept the files. A 3mf contains the model as well as copies of all your settings so it allows us to exactly duplicate your slicing setup.

RE: Customized slicing on part of the model

There seems to be a fine line at which printing more perimeters becomes faster than using infill. Given all those tiny infill areas, this seems to be one of those prints. The added perimeter has the additional advantage of using gap fill, eliminating the different characteristics of each spoke based on position. The part should be stronger as well.

RE: Customized slicing on part of the model

> [..] we can take a look at all the settings you are using [..]

Thank you very much! Here are the zipped files: