Updating PrusaSlicer for 0.25, 0.6, and 0.8mm Nozzle Printing

I just put in my first 0.6mm nozzle and I'm trying to get it to play happy with PrusaSlicer and the MMU. Basically, I've copied the settings for "Start G-code" and "End G-code" from the 0.4mm printer to the 0.6mm printer. The main issue I'm having, at least that I've noticed, is that the initial purge line that gets printed is completely empty. I'm not quite sure why that's the case though. Nothing came out at the purge line. Some did come out about halfway through the skirt though.

This is what I have for the Start G-Code:

M862.3 P "[printer_model]" ; printer model check

M862.1 P[nozzle_diameter] ; nozzle diameter check

M115 U3.10.0 ; tell printer latest fw version

G90 ; use absolute coordinates

M83 ; extruder relative mode

M104 S[first_layer_temperature] ; set extruder temp

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S[first_layer_temperature] ; wait for extruder temp

G28 W ; home all without mesh bed level

G80 ; mesh bed leveling

; Send the filament type to the MMU2.0 unit.

; E stands for extruder number, F stands for filament type (0: default; 1:flex; 2: PVA)

M403 E0 F{"" + ((filament_type[0]=="FLEX") ? 1 : ((filament_type[0]=="PVA") ? 2 : 0))}

M403 E1 F{"" + ((filament_type[1]=="FLEX") ? 1 : ((filament_type[1]=="PVA") ? 2 : 0))}

M403 E2 F{"" + ((filament_type[2]=="FLEX") ? 1 : ((filament_type[2]=="PVA") ? 2 : 0))}

M403 E3 F{"" + ((filament_type[3]=="FLEX") ? 1 : ((filament_type[3]=="PVA") ? 2 : 0))}

M403 E4 F{"" + ((filament_type[4]=="FLEX") ? 1 : ((filament_type[4]=="PVA") ? 2 : 0))}

{if not has_single_extruder_multi_material_priming}

;go outside print area

G1 Y-3 F1000

G1 Z0.4 F1000

; select extruder

T[initial_tool]

; purge line

G1 X55 F2000

G1 Z0.3 F1000

G92 E0

G1 X240 E25 F2200

G1 Y-2 F1000

G1 X55 E25 F1400

G1 Z0.2 F1000

G1 X5 E4 F1000

M221 S{if layer_height<0.075}100{else}95{endif}

G92 E0

{endif}

M221 S{if layer_height<0.075}100{else}95{endif}

G92 E0

; Don't change E values below. Excessive value can damage the printer.

{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3|SOLUBLE).*/}M907 E430 ; set extruder motor current{endif}

{if print_settings_id=~/.*(SPEED @MK3|DRAFT @MK3).*/}M907 E538 ; set extruder motor current{endif}

I'd expect the extruder to extrude the same amount of material from the above code. I could see the above settings being an issue for the 0.25mm nozzle given the smaller diameter of the nozzle, but not the 0.6mm.

Does anyone have proper settings for 0.25, 0.6, and 0.8mm nozzles on the MMU?

RE: Updating PrusaSlicer for 0.25, 0.6, and 0.8mm Nozzle Printing

The lack of extrusion in the wipe area before printing is almost definitely due to my filament sensor failing. The axle in the idler worked its way out, so it wasn't properly triggering the IR sensor. In the process of fixing this issue, the filament sensor will no longer trigger reliably. Need to buy a new one.

I'd still love some suggestions on properly setting up PrusaSlicer for different sized nozzles in the MMU. The copy/paste I did above works decently well, but if there's an error (such as an unreliable filament sensor!) the print pauses, but it doesn't behave the same as the 0.4mm nozzle MMU printing. Perhaps it is due to the filament sensor?

RE: Updating PrusaSlicer for 0.25, 0.6, and 0.8mm Nozzle Printing

Basically, I've copied the settings for "Start G-code" and "End G-code" from the 0.4mm printer to the 0.6mm printer.

It could be that the extrusion profile and/or heat from the 0.4 is too low for the 0.6 nozzle.

What I did when I played with an 0.05 layer height profile back in the 2.0.0 days was compare the MMU 0.2 profile against the Single 0.2 profile. Then I copied the Single 0.05 profile and made the same modifications.

Maybe you should do the same here where you compare the MMU 0.4 config with the plain MK3 0.4 config to find the differences, then copy the plain MK3 0.6 profile and make the identified adjustments.

RE: Updating PrusaSlicer for 0.25, 0.6, and 0.8mm Nozzle Printing

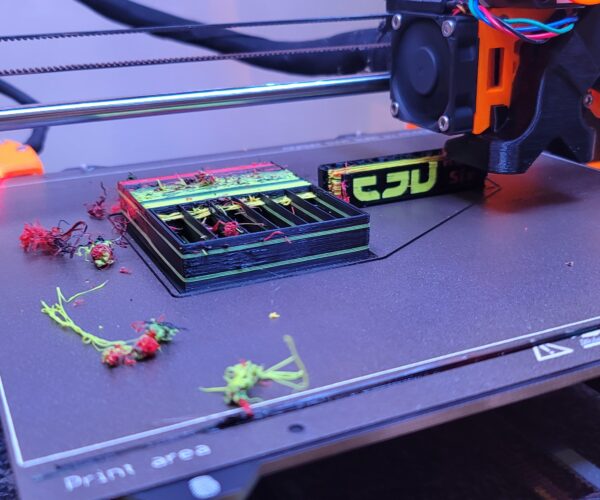

Comparing the profiles is a great idea, I'll do that when I'm back to working on the 0.6mm nozzle. For now, I'm back to trying to get the 0.4mm nozzle to work with PETG and the MMU. I'm getting towers that look like this, which leads to massive blobs building up on the nozzle. I'm having a hell of a time trying to tune this thing. I realized about an hour ago that the sheen on the plastic is dull compared to some of my earlier prints with the original nozzle. I think this means the nozzle is cooler, so my 8th test will include bumping up the temperature a bit.