An Open message to Prusa regarding MMU2

While I am very impressed with the i3 Mk3 printer for consistently delivering high quality prints, I have no kind words to share regarding the MMU2. I have tried to get help from Prusa and have also sent emails, without success.

My candid opinion is that the MMU2 is a Rube Goldberg and is a fussy, finicky contraption that should not have been released.

The MMU is obscure to operate as well as being problematic.

- The buttons on the MMU have different functions in different modes. It's confusing and a poor user interface. And, they don't really seem to allow what I want to be done. For example, when the unit is sitting idle why can't I unload the filament using a button? How do I unload a filament to change it?

- Why do I need to use these three buttons anyway? Why can't I do everything through the LCD screen?

- When there is a problem, the LCD display simply states "There is a problem with the MMU". This message is not very helpful at all. Really, couldn't the message include some more detail of what the problem is and even how to correct it? A message like this can only be a frustration for users.

- The LCD screen will sometimes say to fix the problem on the MMU and the "press a button". What button should I press, there are three of them. When should I press it? Now? To fix the problem? After the problem is fixed? Or do you mean to press the button on the rotary knob? Ot the "X" reset button? This is a sloppy, thoughtless LCD message.

- Towards the end of filament rolls there is a lot of curl in the filament. The MMU has shown to be quite intolerant of this curl, with the filament sometimes jamming and sometimes sprouting out of the MMU entirely.

- If you tighten the two spring-loaded screws too much the MMU is unhappy. If they are too loose the MMU is unhappy. But there is really no way to know if the screws are set correctly. It turns out that I took the printed manual too literally where it said that quite a bit of force needed to be applied by the screws and I had tightened them down too much...of course nothing whatsoever tipped me off that this was the problem.

- I have to open up the MMU so often that the two spring loaded screws really should be latches or else be thumbscrews or else be captive. I am just tired of them falling out and the springs getting lost in the carpet. It should be quick and easy to get into the unit, since it seems the screws need to be undone to remove and change filament.

- The filament frequently catches on the 2" long short flared PFE tubes when being auto-changed. This seems to happen more towards the end of a spool. A larger funnel might solve this. Or...something to eliminate the need to load into a tube-end. This is the MOST common problem I am having.

- The PFTE tubing is so long that it has a lot of friction. I find that some types of filament (especially PVA and flexible) are somewhat sticky and cannot be pulled through because of the tube lengths. Seems like a bad design. Perhaps the initial feeder tubes could be significantly larger and friction free, such as using ¼" polypropylene tubing.

Some functionality that I would expect isn't implemented. Consider these as suggestions:

- The MMU should be able to be controlled entirely through the LCD screen. Or, the LCD screen should show what the current function of the three buttons is at the moment.

- I cannot find a command to back the filament entirely out of the MMU so I can change it to a different type. Perhaps it is there, but I haven't located it. There should be a straightforward way to remove a filament from the system.

- Error messages should be informative and not just say "There is an Error in the MMU".

- There should be the ability to specify a "continuation spool" for each MMU filament. That is, when Filament X is empty then the reserve would be Filament Y. This would allow using filament down to the very end of a toll even on multi-color prints. I know which spool is getting near the end and I could always use position 5 for a "continuation" of the one that I expect to run out. Basically, each Filament Position could optionally specify one "continuation" position to auto switch to. It would make using up your supplies easier. (There is a feature a little this this, but only for single-color prints.)

The MMU is the start of a good idea, perhaps. But it isn't a good product yet. It is an idea that really needs refinement and polish to be something of equal quality as the printer itself.

RE: An Open message to Prusa regarding MMU2

While I don't necessarily want to dog pile on this, I have to say your concerns match my own that I've been biting my tongue about for a year assuming I was just using it incorrectly or not enough to dial things in. I jumped on the MMU2 upgrade as soon as it was available because I was impressed at the thoughtfulness that Prusa typically puts into their users' experiences. However, I must say I've been really disappointed in the MMU2 experience and have not been able to use it for what I had hoped. I mainly wanted to use it with dissolvable support material, but I find it to be so temperamental that it's been impossible to use without constant babysitting through filament changes. And while it's convenient to have a few different filaments queued up to print with, the filament buffer and spool holders take up an absurd amount of space, not to mention how frustrating it is to try to get filament loaded into the filament buffer.

The one thing I might correct about your concerns is that there is an Eject command on the LCD screen that unloads filament from the MMU2. Otherwise, I agree with everything else you've said.

Prusa MK3S/MMU2S

Prusa SL1/CW1

RE: An Open message to Prusa regarding MMU2

That says it all!

RE: An Open message to Prusa regarding MMU2

I've had the stl collection bookmarked for a while but haven't gotten around to testing any of the changes myself

Prusa MK3S/MMU2S

Prusa SL1/CW1

RE: An Open message to Prusa regarding MMU2

- I have to open up the MMU so often that the two spring loaded screws really should be latches or else be thumbscrews or else be captive. I am just tired of them falling out and the springs getting lost in the carpet. It should be quick and easy to get into the unit, since it seems the screws need to be undone to remove and change filament.

Yes i agree, it is very annoying that there is nothing preventing the screws and spring from falling off, especially considering the angle they end up in when you open it.

And no you should not have to open the cover to change filament

- The filament frequently catches on the 2" long short flared PFE tubes when being auto-changed. This seems to happen more towards the end of a spool. A larger funnel might solve this. Or...something to eliminate the need to load into a tube-end. This is the MOST common problem I am having.

I assume you mean the 5 short ptfe tubes that are chamfered on one side and flat on the other one.

I think the instruction is unclear what side goes where and if you follow the instruction you probably end up with the flat side towards the 5 bondtech gears inside the mmu.

This i think is wrong so i have changed it so chamfered side is pointing towards the 5 gears and i have no problem where mmu is unable to push out filament thru the gears and selector.

also i don't get why prusa don't chamfer both sides and then there is no right or wrong way.

RE: An Open message to Prusa regarding MMU2

i don't get why prusa don't chamfer both sides and then there is no right or wrong way.

This is an excellent suggestion! (Hello Prusa!)

There are a number of instances where you will get things wrong of you follow the manual. The manual is just flat-out wrong sometimes.

What Prusa has apparently never done is hand the kit to somebody unfamiliar with it, and then tell them two assemble the kit while they watch and take notes. The assembly person must follow the manual and to do nothing that isn't printed in it...don't guess or infer. Perhaps have a non-technical person do the assembly.

The MMU is the start of a good idea. But a smart industrial engineer could definitely make it simpler and more reliable.

The hallmark of a Top Tier company (like Apple) is that they take care of all of the fussy details...like the spring loaded screws falling out, or how it requires a tool to simply change the filament.

Prusa gets it all 90%, while their competition maybe gets it 70%. But there is room for improvement. For Prusa to continue to capture their premium price they will need to learn the discipline of paying attention to the details. Somewhere inside their company they have this skillset because they exhibit it well on their Prusament QR codes and in other areas.

The MMU2 is still a Rube Goldberg device that is badly in need of polish.

RE: An Open message to Prusa regarding MMU2

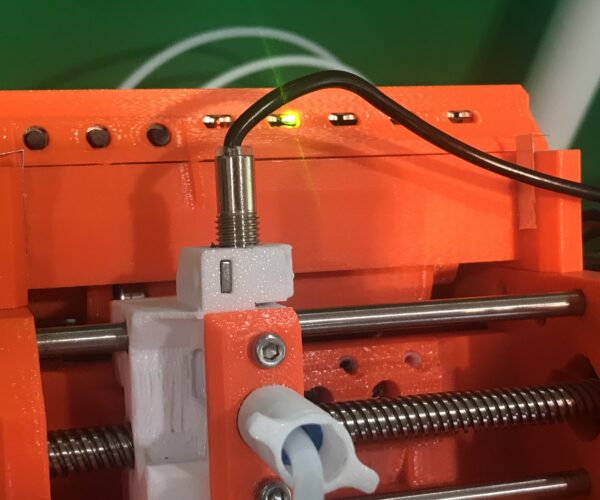

Here's a screw and spring saver kludge. Cut two strips from a soft drink can, about 6mm by 20mm, and bend a lip at the end as shown. Superglue them to the MMU2 as shown, with the glue just in the bottom 8mm say, so there's a long springy area. They move out of the way easily when you insert a hex Allen wrench, but generally catch the screw/spring before it falls out.

RE: An Open message to Prusa regarding MMU2

One of the first things I did was to print the extension knobs for those spring-loaded screws. Saves a lot of futzing around.

RE: An Open message to Prusa regarding MMU2

@jsw

Where does one find the extension knobs to print?

RE: An Open message to Prusa regarding MMU2

@jsw

Where does one find the extension knobs to print?

Here's the ones I used, except I printed them in Orange PETg to match the other printed parts.

https://www.prusaprinters.org/prints/31158-prusa-mmu2s-thumbscrews-for-idler-tensioning

RE: An Open message to Prusa regarding MMU2

@jsw

These seem like a nice improvement, but I can’t figure out what keeps them from falling out and letting the springs go loose?

RE: An Open message to Prusa regarding MMU2

@jsw

These seem like a nice improvement, but I can’t figure out what keeps them from falling out and letting the springs go loose?

I haven't had any issues with the springs falling out, either with the screws alone or with the knobs. These need a 40mm screw to make up for the space consumed, and the screw heads fit tightly in the knobs. If I had any issue with the springs, I might tack them on to the knobs with a very small dab of something like Mike's Hobby Glue.

RE: An Open message to Prusa regarding MMU2

@jsw

I too wondered about the Prusa design on the tension spring/bolt design and spent several episodes looking for the spring.

The long adjustment knob remix helps unbalance the assembly so the bolt catches, most of the time, on something in the hole and doesn't drop out.

RE: An Open message to Prusa regarding MMU2

@jsw

I tried attaching the springs to the original screws, using Bondic, but then the spring drags harshly on the plastic when you turn the screw. Otherwise the head of the screw slips easily against the spring, so the plastic doesn't get dug up. So I wouldn't glue the spring to the screw unless perhaps also adding a smooth washer on the bottom end to protect the plastic body.

I found the original design very annoying, because I have to open the selector often to fix something or other, and frequently that resulted in a long hunt for dropped screws and springs.

RE: An Open message to Prusa regarding MMU2

Forgot to mention that I added small SS washers between the spring and the knob. Couldn't bear the sound of the spring against the PETG.

RE: An Open message to Prusa regarding MMU2

Yes, a washer might help here, and I'll put this on my mental do-it list to do in the near future. Thanks.

RE: An Open message to Prusa regarding MMU2

I documented how I get perfect prints nearly 100% of the time ...

https://www.hcd.net/prusa-mmu2s/Prusa-MMU2S-Reliability-Modifications.htm

... maybe this will help someone.