NEEDED: Help with ABS printing.

Hello all,

I have just started printing with ABS (having gotten PLA down really well). I am now making functional parts and need a more durable plastic. I really like ABS and that is what I want to use (so please no suggestions to use other materials). I have a part that I am trying to print and for the life of me I can't get it. The first time I printed it it actually worked, but the design was not correct and I wanted to make some changes and fix the dimensions (it's a case for a joystick and the joystick did not fit the first time).

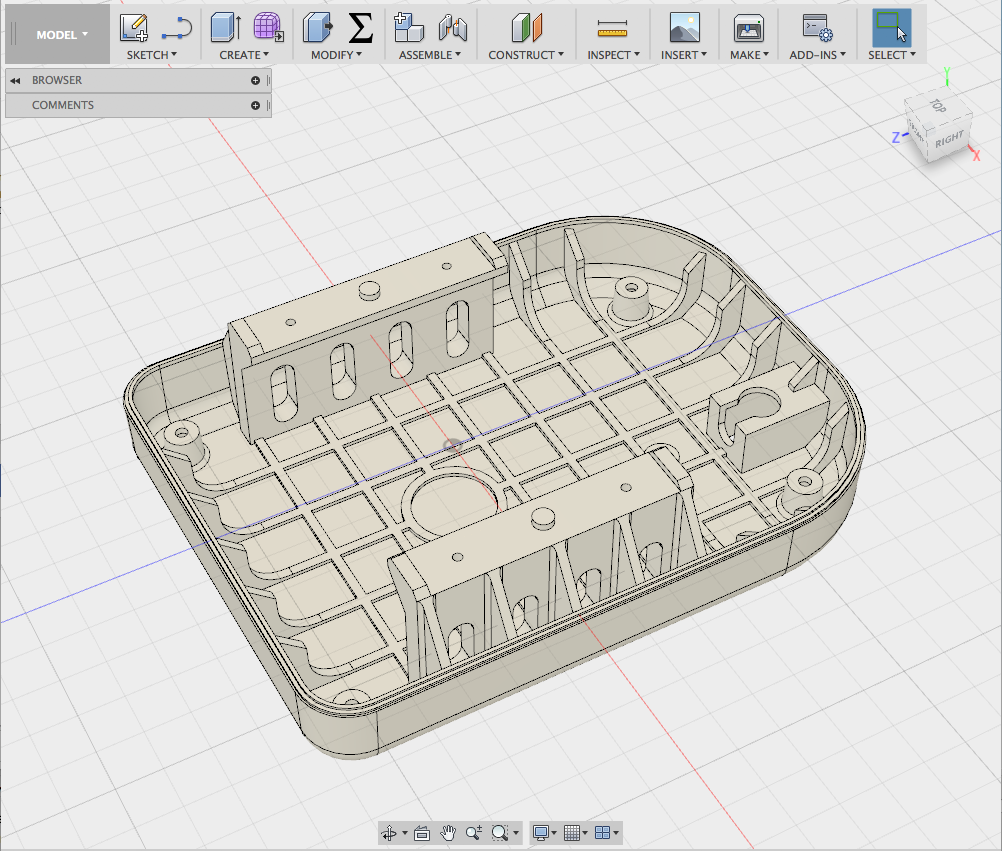

This is what I am trying to create...

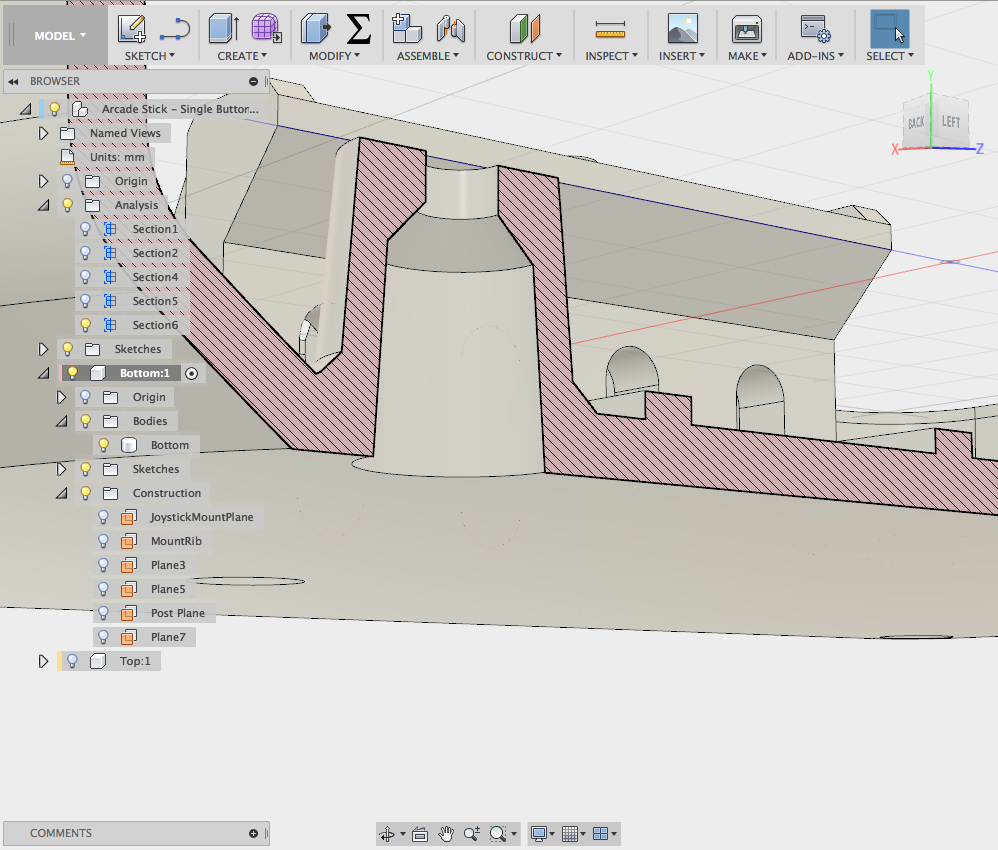

Now the issue is the post for the screws (there are 3 of them). For some reason they are being destroyed when I print. The inside is beveled at a 45deg angle so that it will print without supports.

Here is a cross section:

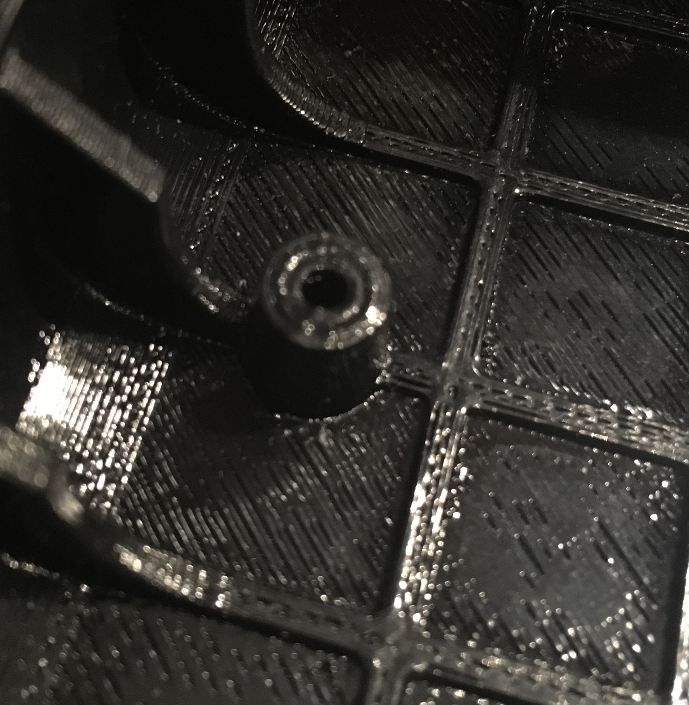

But this is how it prints:

Now that is one of the better ones. Others I have tried came out completely mangled.

But the stupid thing is like I mentioned before the first time I printed the model these turned out perfect. So you might say well what did you change? I changed a few parameters in the model. Nothing to the post. Also I changed a few printing parameters but when this led to disaster I set everything back and it was still a mess.

So what have I tried?

My first print that worked was 0.20 layer height 100/250deg (bed/hotend) - no cooling fan. However I have the feeling that is too hot. As the first layer after infill was getting messy.

Now further prints at this temp fail - always. So I tried to print again at 100/250 (with a small 20% fan speed). Now this yielded a really great print but the post still got destroyed. In fact it was my intention to lower the hotend to 240 but the settings did not take properly and it printed at 250.

So I printed again at 100/240 (and a 10% fan) - again nice print overall but the posts where even MORE destroyed. Now I also changed the minimum print speed (40% of 50mm/s it was 20%), AND I only printed a 1/4 of the model.

I guess I would like to know from anyone that has insight is, is 240 still too hot? What would the minimum print speed be for ABS on a MK2? I print in an enclosure - I had zero luck printing without it.

Any advice would be helpful. I will post additional pics in the next post.

Thanks

Jason

Re: NEEDED: Help with ABS printing.

I think some of this is going to depend on the ABS you are using. I am using 747 and 758.

I have typically printed at slightly higher temps 260-265 and what appears to be a lower Z than what you print with. My best success has been with the layers actually touching, instead of the bands I see here.

I would strongly suggest a quick calibration test model for your screws, with different temps to see what you get, and try the lower z settings. It may do the trick

Re: NEEDED: Help with ABS printing.

I think some of this is going to depend on the ABS you are using. I am using 747 and 758.

I have typically printed at slightly higher temps 260-265 and what appears to be a lower Z than what you print with. My best success has been with the layers actually touching, instead of the bands I see here.

I would strongly suggest a quick calibration test model for your screws, with different temps to see what you get, and try the lower z settings. It may do the trick

The banding is a bit exaggerated in the photos. In real life it's not that bad. Also the layers are bonded well. Just in these areas... Interesting about printing hotter... perhaps I am going in the wrong direction. I just tried one more and failed again. I will try hotter and see what happens... thanks for your reply.

I am using AMZ3D ABS - it's not bad.

Re: NEEDED: Help with ABS printing.

My experience thus far is that ABS likes to stick to things that are warm. So either increase the temp to get them to bind and increase the heat to the bed to keep things a bit warmer. When I struggled with ABS I found that ultimate solution was a small closet kept at 90 deg F. I don't know if the power supply liked being that warm, but the issues I had all but disappeared.

Set the bed to 109 and give that a try as well.

If all else fails, print the posts one at a time and use some Acetone to glue them in place. ABS and Acetone together are beautiful things.

I think you'll find the posts print great one at a time...

Re: NEEDED: Help with ABS printing.

My experience thus far is that ABS likes to stick to things that are warm. So either increase the temp to get them to bind and increase the heat to the bed to keep things a bit warmer. When I struggled with ABS I found that ultimate solution was a small closet kept at 90 deg F. I don't know if the power supply liked being that warm, but the issues I had all but disappeared.

Set the bed to 109 and give that a try as well.

If all else fails, print the posts one at a time and use some Acetone to glue them in place. ABS and Acetone together are beautiful things.

I think you'll find the posts print great one at a time...

I am not sure how hot it gets in my enclosure. I do know the power supply gets real hot so I agree that the power supply won't like it. I am thinking about separating the two.

I have tried two prints and no luck. But now that I think back I think my first print was at 0.15, that's possibly why it worked. I am doing another test print at that layer height to see if it works. It's a little annoying that I can't print at the height I wanted. The model is fine tuned for 0.2 but I can adjust it. Thank god for parametric CAD.

I think what is happening is it's printing the posts way too fast.

Re: NEEDED: Help with ABS printing.

Wanted to post an update in case anyone is interested.

TLDR; I have solved the issue, problem was excess vibration in the print bed.

In order to test different settings I started to print small test pieces, these included a post and a section of wall (with a radius). Now I got lazy and did not want to prepare the print bed with hair spray every time and I just moved the model around the bed each print. This lead to me discovering the issue. As I moved the part closer to the front the issue worsened. To the point where the wall also failed at the radius. I turned out that during circular movements the printer was vibrating too much.

Why you ask? Well because I half assed a bearing swap 2 months ago. I wanted to swap the Y axis bearings for SKF ones. I did so by taking the printer apart as LITTLE as possible. However when I reassembled it there was a very slight shimmy in the print bed (if you grabbed it you could very slightly rotate it). I adjusted it but for whatever reason I just could not get rid of it. I was not sure if it was the bearings or the assemble. Anyway I ended up spending HOURS trying to get it to properly XYZ calibrate. And finally I got it, it was frustrating and in the end I was not able to get it perfect, but the software can correct for it so I just had to get it to the point where it said that it could do that.

So what happened? I have been using the printer a lot over the last several months. And over that time the shimmy got worse - I didn't really notice as I tried not to rotate the bed back and forth so as to not make it worse. But once I did I noticed it was way worse then before.

At this point I had little choice, I had to disassemble the whole Y axis and rebuild it from the start. Now a month or so ago I had acquired a new set of Drylin bearings and the intention was to replace all the bearings (in all axis). I never did it because if time and I knew it would be a pain in the ass. But with this problem I took this as the opportunity to do it.

So I set aside 6 hours and I pulled the printer apart and reassembled. I took my time, and I followed the assembly closely and it paid off. I put the printer back together, the bed was tight (no shimmy) everything moves as it should. I also was able to get a perfect XYZ calibration the very first time I tried.

I printed the part again and although it had one issue (it was over extruded because I tried a different technique for determining my extrusion multiplier, I got a number that was very different then I was using before. I tried it but it was no good). The posts themselves printed perfectly, same temperature as before and the same layer height.

Thanks to everyone that posted suggestions.

Jason

Re: NEEDED: Help with ABS printing.

Thanks for taking the time to post the outcome 🙂

Re: NEEDED: Help with ABS printing.

This is good information and is likely to help others. Thanks for posting the outcome.

Do you think the bearings were faulty on installation.