Super frustrated with anything ABS. Any tips?

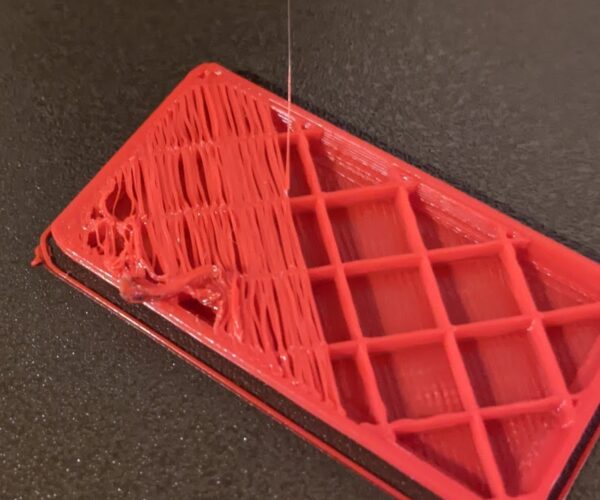

I have my printer dialed in with PLA, have printed tons of stuff that works out well. But I can't for the life of me to get ABS to print well. I always get goopy first layers no matter how much I adjust Z (even with settings that result in great first layer with PLA) and inconsistent printing like the attached photo is happening all the time.

My printer is in a warm space with no draft, so I really can't figure it out. I'm slicing the STLs in PrusaSlicer, selecting Hatchbox ABS (my brand), using pretty standard settings (.15 or .20 with 10% infill). Is it possible that I just absolutely need an enclosure to get consistent results with ABS on the MK3s?

RE: Super frustrated with anything ABS. Any tips?

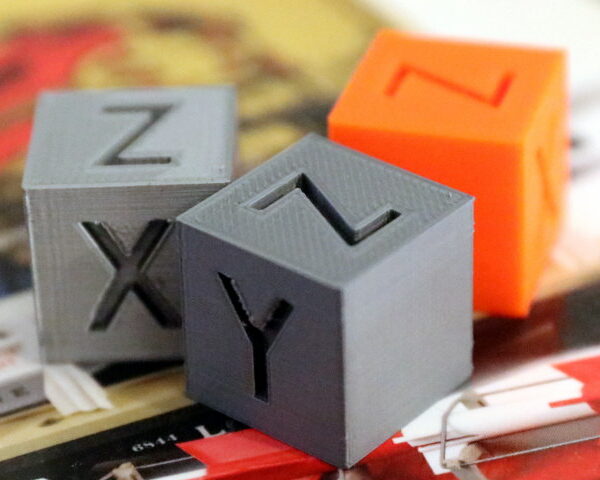

I do quite a bit of ABS printing on the MK3S and have had very good luck. Hatchbox is my go-to brand for most every type of filament, and I know the quality is consistently good. The leftmost cube below is ABS, PLA in the center and PETg on the right. I know the MK3S is capable of excellent ABS prints.

The first thing that I noticed is that your infill of 10% looks too sparse. The machine has to bridge over the infill and it looks like it's drooping and incomplete, possibly resulting in the blobbing you reported.

Your bottom layers and infill appear to be printing properly, so it does not look like anything major.

If this were my print, I would first try bumping the infill to 20 or 25% with a gyroid pattern.

Before I got the enclosure, I was totally sold on the 'draft shield' as improving overall ABS print quality. It's under the skirt and brim options and I suggest two loops. It's kind of like a mini-enclosure around the print. I would recommend using this.

A couple other general hints I've found out work well with ABS (but may not specifically apply to this case) are to be sure to let the machine preheat and stabilize maybe 15 minutes or so before starting the print. Then when the print is done, let it cool to almost room temperature before trying to removing it from the build plate.

RE: Super frustrated with anything ABS. Any tips?

@jsw

Thank you! This is really helpful. I'll make the adjustments and see how it goes.

RE: Super frustrated with anything ABS. Any tips?

ABS printing, your top looks normal, ABS settings is without fan(part cooling fan), so the ABS will droop down.

You need to use the fan wen the bridging starts.

If you use the fan , the parts will gets not as strong, ABS should be printed without fan.