Squashed/Streched Hole/Circle in X & Y Axis

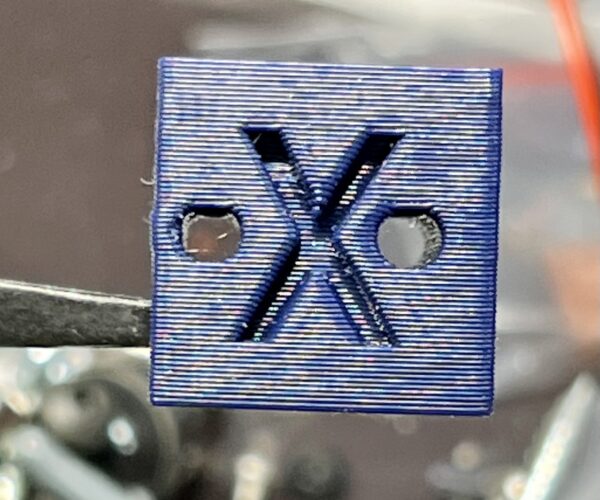

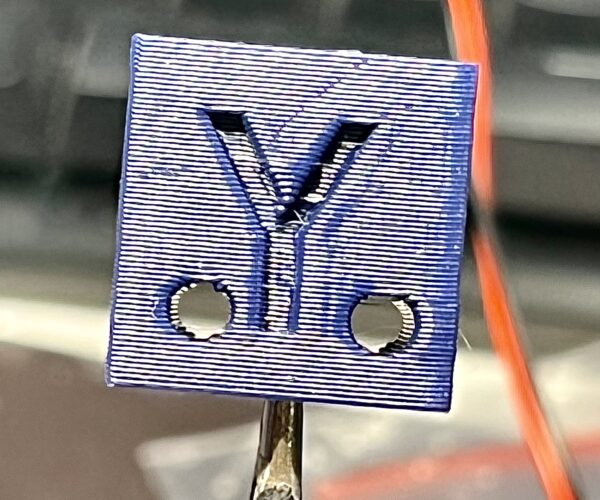

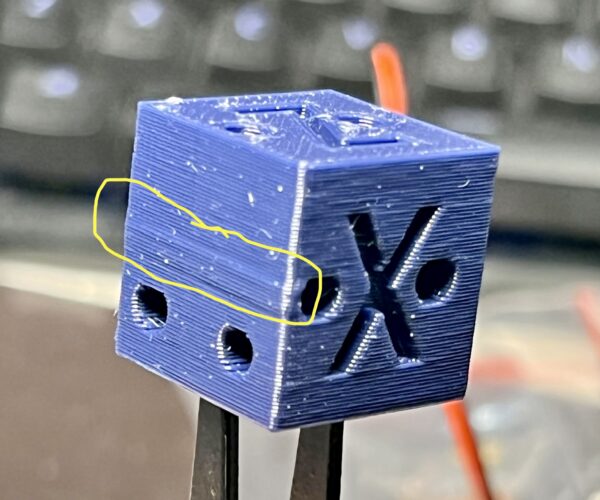

So investigating why does my machine when printing Holes / Circle in X & Y axis always streched. So i printed 20mm XYZ Calibration Cube

MK3S+ , PrusaSlicer 0.3mm , Generic PLA

belt tension X 254 Y 257 all nicely tight

if the hole facing Up (Z Axis) it was perfectly rounded

but if on X / Y axis it always streched, kindly any help?

Best Answer by FoxRun3D:

That's how things work. The last layers at the upper end of the holes have an inward curvature, to the point that the topmost ones print on thin air, so they sag. Horizontal holes should be perfect (as perfect as printer properties and tesselation allow) but vertical holes usually sag. You can try to compensate for it by designing tear shaped holes or drill holes out later.

The ribs you circled are probably a manifestation of the bulge effect--google for "prusa bulge" and you'll find 20+ pages of discussion--but no universal solution. You may want to try to adjust your extrusion multiplier.

RE: Squashed/Streched Hole/Circle in X & Y Axis

That's how things work. The last layers at the upper end of the holes have an inward curvature, to the point that the topmost ones print on thin air, so they sag. Horizontal holes should be perfect (as perfect as printer properties and tesselation allow) but vertical holes usually sag. You can try to compensate for it by designing tear shaped holes or drill holes out later.

The ribs you circled are probably a manifestation of the bulge effect--google for "prusa bulge" and you'll find 20+ pages of discussion--but no universal solution. You may want to try to adjust your extrusion multiplier.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Squashed/Streched Hole/Circle in X & Y Axis

Thank you very much! You are very helpful!

That's how things work. The last layers at the upper end of the holes have an inward curvature, to the point that the topmost ones print on thin air, so they sag. Horizontal holes should be perfect (as perfect as printer properties and tesselation allow) but vertical holes usually sag. You can try to compensate for it by designing tear shaped holes or drill holes out later.

The ribs you circled are probably a manifestation of the bulge effect--google for "prusa bulge" and you'll find 20+ pages of discussion--but no universal solution. You may want to try to adjust your extrusion multiplier.