Ripples on print surface

Hello,

yesterday I printed some plates from PLA.

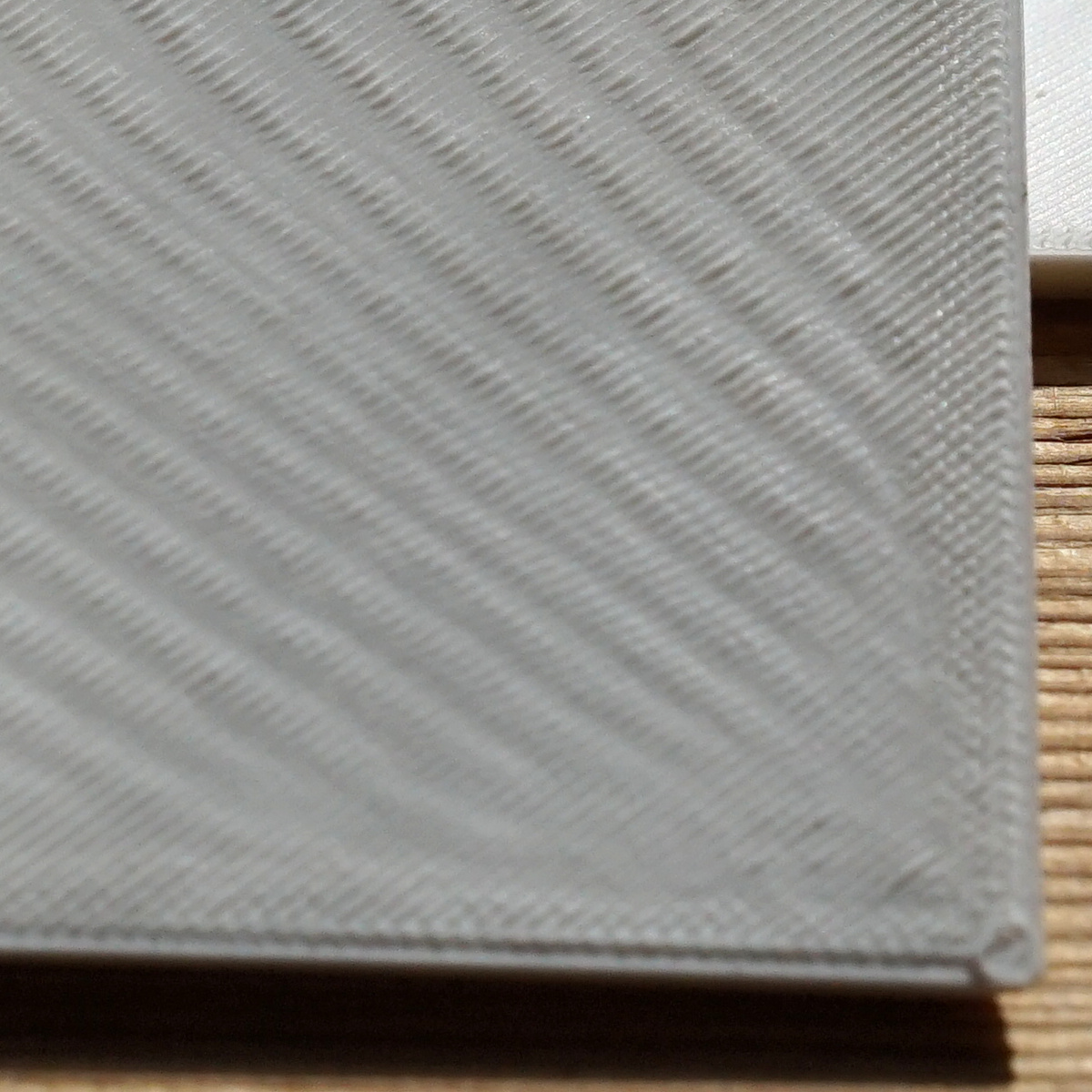

After adjusting some parameters, I got the following result (extruder 225°), which I considered to be not so bad (for my limited skills)

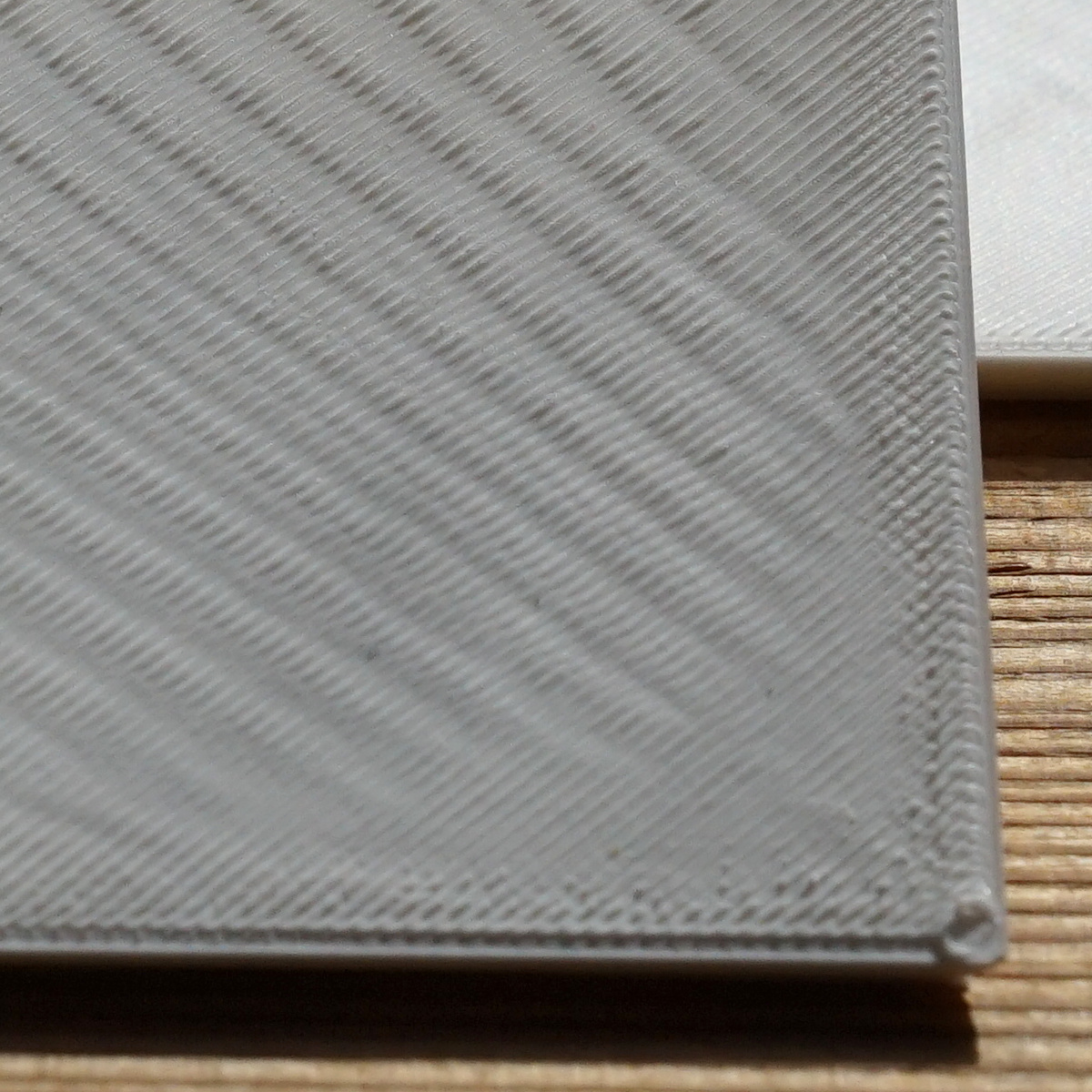

After some reading in Prusas Forums I lowerd extruder temperature to 200°, which resulted in:

I readjusted the temperature to 225°, but nothing changed, see the following picture

What is the possible cause of this ripples?

As this is the back side of the part it is no real problem. But in the process of getting better prints I would like to understand what is going on and remove the cause of the ripples. Thanks for reading!

RE: Ripples on print surface

If thats the top surface of your part then its a combination of not enough infill % to support the top layers and not enough top layers to allow it to even out (although not enough infill % can lead to it never getting to even out anyway).

RE: Ripples on print surface

Thanks for your answer!

Yes, its the top surface. But your reply can not explain why the first sample looks good, the two later ones do not. I changed neither infill nor number of toplayers.

RE: Ripples on print surface

With insufficient infill what you are in effect doing is printing bridges, how well things bridge depends on a wide number of factors. Including ambient air temperature. If the later 2 were warmer to start with the bridge lengths can sag more, or even curl up more. This leads to the initial uneven surface and that can snowball.

Try it again with more infill, you will soon see that is the cause. Its one reason I generally use Super Slicer (a fork of Prusa Slicer) as that has the option to do a 48% infill layer just before it does the top layers which stops these sorts of issues and still allows you to use low infill %.

With Prusa Slicer you can apply a modifier to that area and bump the infill % up in a thin section to achieve the same result but it can get tricky placing a modifier in just the right spot, especially on tricky shapes.

RE: Ripples on print surface

OK, thanks, I will give it a try 😉

RE: Ripples on print surface

You haven't given much information to go on, however I do not believe that is an infill issue. If it was me I would first check my bondtech gears make sure they are clean,(No filament stuck in the teeth that push the filament). If they are clean then make sure that you don't have any loose screws or bolts on your printer chaise (basically give them all a once over), and I might also try re- calibrating the Z axis. If you find loose screws or nuts them tighten them and do a full re-calibration.

Good luck,

Dan

The Filament Whisperer