PETG, prints contracting off of the bed... Is there a good fix?

Hi all,

I'm trying to print out a fidget thing, link to which is here:

https://www.thingiverse.com/thing:2850756

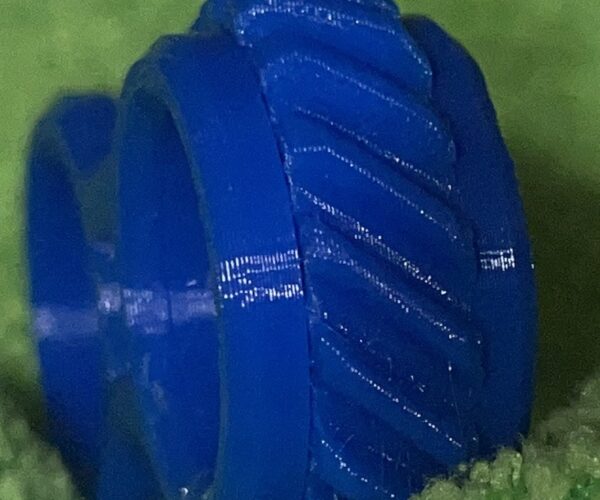

So, the part I'm trying to print is labeled as the 'housing.' Image is attached. Basic idea is that two of these should fit together, cylinder on one should socket into the matching depression on the other identical piece.

I opened up the model in CAD, the cylinder is dimensioned to be .5mm smaller in diameter than the socket. But, printing it on a textured bed in PETG, the cylinder ends up being .5mm bigger. Becuase it's one solid piece, the XY compensation won't really work, I don't think, because it would adjust both the cylinder and socket.

I suspect it's something to do with the socket contracting after it's off of the heated bed. I'm not sure how to adjust for that.

At the moment, I'm testing the hypothesis by printing it upside down, with supports, and hoping the gears still spin freely enough to not be vexing for the intended recipient. So we'll see how that goes. Having the socket come out good, with a contracted cylinder would certainly join more cleanly.

But the joy of coming in here is absorbing the accumulated wisdom. Does anyone have any other suggestions?

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE:

So, flipping the part definitely reversed which side contracted, so everything did come together well. I also have other suspicions to test later, about what would help keep the socket from contracting... but all in good time.

My original question remains, though: Are there other adjustments that would help with this?

Thanks in advance to any and all...

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE: PETG, prints contracting off of the bed... Is there a good fix?

.. I was bored .. so I printed the model and downloaded the STL into Fusion 360.. When I measured the housing sizes.. I found them virtually equal. I see no 0.5mm difference that would allow one to fit inside the other.. there are some bevels.. I'm thinking maybe you measured the wrong item when you used your CAD s/w. although there should be some difference between the 2, they likely both shrink at about the same rate. I printed 2 housings and they actually fit with only slight persuasion. Likely the author did too.. and so he saw no need to make the housing smaller. I printed both in PETG, @0.15 layer, surprisingly one fit inside th other quite well.. Eryone PETG, @230/80C on rough sheet. 4 perimeters.. 5 bottom, 8 top. MK3+ printer

The gear was very difficult to print. It has only 1 wall thickness and then the gear teeth are attached. That is too narrow to be easily printable. The footprint is very small on the bed and the teeth are making constant retractions. As the model finished, it often detached from the bed plate. I had to really dial in my Z height more and use a bit more bed heat.. up to 85C. One of my filaments was older than the other and it was a bit more stringy and I could not use it.. Eventually got a gear printed ok. If you look at the slicer output (pic below), you see that every tooth is an individual circle of filament. That means a circle and a retraction.. those dots are killer. So easy for the filament to glob a bit (get a bit higher) and then in next pass to hit it and knock it off.. Also prone to stringing between teeth.. If you have more walls in the middle and fewer teeth, then you get lines that are continuous around the model that form the teeth & the wall and much less of the individual yellow areas you see in the pic. (and more reliable).

So I also set my print to 75% speed on the LCD menu for the gear..

When it was all done, I installed one gear and snapped the housings. They both press fit. The gear moves reasonably freely but does not spin on its own. Not sure what the 'feel' is supposed to be, but I think its actually the way it was intended. Mine stays together without glue. But I think this model is quite dependent on your printer setup, your z height and having good filament.

RE:

I was measuring in Solidworks. At the top and bottom of the circle, there’s a pair of triangles that meet at a centerline, forming an isosceles. I measured across those.

For the gears, used novamaker. No issues on the gears, though I printed at 110% scale. For the housing, I used new Prusament, using the prusament settings on textured bed.

So… who knows.

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE: PETG, prints contracting off of the bed... Is there a good fix?

I'm just adding my 2 cents in here. I remember printing this for my girlfriends son 4 or 5 years ago out of PLA, if I remember correctly it started off being very tight, and within a couple of days had worn to a very usable point. You might even consider a q-tip of white lithium grease before assembly.

RE:

I just printed the other gear. I think my first PETG filament was damp and so didn't work. 2 different colors worked fine for the gears although I decreased my Z slightly, increased the bed temp and slowed the printer to 80%. I printed everything at 100%. It all fit fine and the gears work pretty smooth. Some grease might help, but over time the plastic will get smoother and it will work better. I'm not sure why yours is shrinking so much. So my finding is that both parts of the housing have the same dimensions and shrink about the same and thus fit okay. The gear is about 0.25mm larger. I think everything shrank at about the same rate. For me, both gears spun okay after working them in a bit. I did a little light sanding inside each gear. Maybe dumb luck, but one of the first models like this that actually goes together on my machine almost perfect.. so can't offer any help, unfortunately.. Assume you have similar temps to my settings above.

RE: PETG, prints contracting off of the bed... Is there a good fix?

@crab

Forgive me if I'm thinking of the wrong user, but I seem to recall you mentioned having a Printdry system, if you print directly from it you should never have to worry about wet filament. I'm probably thinking of someone else.

RE: PETG, prints contracting off of the bed... Is there a good fix?

yes.. but the printDry box stores only 2 rolls. I have about 10 active at any one time. 5 x PETG and 5 x PLA. I have them all in dryboxes of some type.. generally homeMake boxes using clear cereal containers with dessicant.. but some moisture will get in virtually any dry box. The older the filament the more moisture gets in. I'm near the sea so it is nearly always above 80% humidity. That is a problem I constantly have. I only actively dry stuff as I notice it starts to string or hiss.

@crab

Forgive me if I'm thinking of the wrong user, but I seem to recall you mentioned having a Printdry system, if you print directly from it you should never have to worry about wet filament. I'm probably thinking of someone else.

RE:

@crab

I live less then 100' Feet' from open water. I print from my print dry, with every print because of this, I experience no issues with any print because of this. I also use an foodsaver system based on the recommendation of a user here "Swiss_Cheese" to persevere my filaments. This has served me well. My filament at no time has been exposed to humidity, relative to where I'm located, and has been in a perfect state, with regard to relative humidity, and my location. I think you should consider this.

This user has obviously taken this into account. You should look into this.

RE: PETG, prints contracting off of the bed... Is there a good fix?

Well, my working theory is that some of it was due to extra perimeters. (I used 3.) I’m guessing that the base with the socket would have contracted equally, but the structure of the cylinder held that part at the original dimension, where the socket did not, so it tightened up.

Just a guess, though. I’ll have to design something that helps me to test that theory.

Also, basement isn’t freezing, but isn’t exactly room temp. That’s probably having an effect, too.

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE:

@jdubs

All material that you can print shrinks, they shrink at different rates and amounts based on the type of material, while heat from the bed can effect this, in the end they shrink evenly based on the shape, and material type, there are many articles about his on the web, and information to help compensate for this, should you find it necessary. With regard to the basement I would be most worried about humidity, and progress from there. If your printing parts meant to go together out of different materials, then I would worry about shrinking.

RE: PETG, prints contracting off of the bed... Is there a good fix?

Oh, I’m well aware. But the area on the part that shrinks the most seems to be whatever was on the bed. I could run a cooler bed. But I don’t want to cool the bed so much that I lose the print.

It’s wintertime, so the air is dry. So I’m less worried about that as I am temp.

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE: PETG, prints contracting off of the bed... Is there a good fix?

@jdubs

You can compensate for the cooler bed temps by using products like Layerneer or Magigoo. Layerneer original has worked a treat for me.

RE: PETG, prints contracting off of the bed... Is there a good fix?

Smooth sheet? Textured?

-------------------------------------------------------------------------------------------------------------------

In theory, there is no difference between theory and practice. In practice, there is. -Yogi Berra

RE: PETG, prints contracting off of the bed... Is there a good fix?

I have Smooth, Satin and Textured you can use the formula on any of them.

Smooth sheet? Textured?