Help on ABS+ Printing Voron Parts

Hello!

trying to save cost I tried to print on my Prusa MK3S+ with a satin sheet, phaetus copper nozzle 0.4 with an enclosure,

I use eSUN ABS+ and using eSUN ABS Settings preset prebuilt on Prusa Slicer. fan: 15%, Nozzle: 255, Bed: 110

the requirements are:

Layer : 0.2mm

Wall : 4

Top&Bottom : 5

Infill: Grid 40%

This is what I get:

Corners are wrapping here and there, also, I did tried to use brim 5mm around outer objects, but not help much,

there is a sample photo of my bottom so can check the first layer, but it seems okay

how to avoid this wrap? i dont want to use slurry or painters tape since its ruining my bed surface.

satin sheet is capable of printing ABS from this Prusa material tabele https://help.prusa3d.com/en/materials

RE:

I always use Layerneer when printing with ABS, both as an adhesion booster and as a release agent.

I do this on the smooth and textured plates on the Prusa, and with the glass plate on my 'other brand' of printer.

I would think there would be more risk of textured plate damage without a release agent, since, if anything, ABS tends to stick too firmly. I've had two incidents of ruined PEI coatings over the years due to pieces pulling off when removing ABS prints, one without a release agent, while first climbing the learning curve on the PEI sheets, and again on a well-used PEI sheet with a release agent.

RE: Help on ABS+ Printing Voron Parts

jsw,

When printing ABS with Layerneer, what bed temperature do you use? I see they recommend 80C.

RE: Help on ABS+ Printing Voron Parts

jsw,

When printing ABS with Layerneer, what bed temperature do you use? I see they recommend 80C.

For most ABS on the Prusa, I use what PS has for presets unless there's a very specific reason not to. These are usually 100c on the first layer and 110c on other layers.

Layerneer suggests 80c for ABS, but you have to remember that Layerneer was originally intended for glass plates, and they appear to have removed that statement from the newer bottles. My 'other' printer (Ultimaker), which uses a glass plate, has default temperature of 85c for ABS.

Hatchbox, which makes the ABS filaments that I mostly use, recommends 55c to 85c.

So, there you have it, numbers from 55c to 110c. Intuitively, that looks like a 2:1 ratio, but if you look at that relative to 0 Kelvin, it's only a 1.166:1 ratio or a ~16% difference.

I've always used the Prusa defaults on the I3 when printing with ABS. Why? Because it works, at least for me.

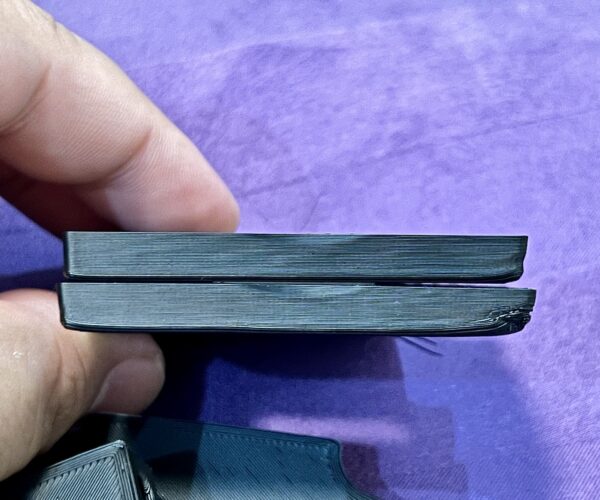

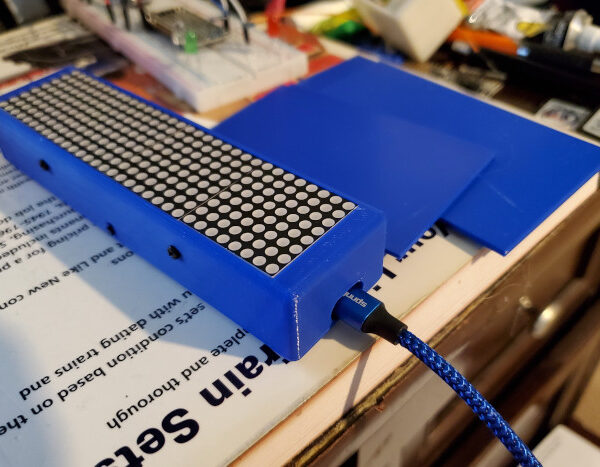

The objects in the photo below were printed with Hatchbox ABS on the Prusa using defaults. These are a small (~6"/150mm) project box and a stack of 2mm slide-in covers of similar sizes.

Everything is square, flat, and solid with no warping and no (significant) shrinkage. All were printed using Layerneer. All of them stuck to the plate without warping or curl-up on the corners. All of them released easily by flexing, after the build plate was cooled to almost room temperature.

I figure that the manufacturer of the printer, specifically the manufacturer of the build plate, knows best as to what temperatures work best on their build plates for the COMMON (emphasis) filament types. I've had good luck using the manufacturers' defaults on both the Prusa and the Ultimaker.

You will notice that the OP of this thread referred to using eSun "ABS+", which means to me that this may be a nonstandard plastic formula. The OP printed using eSun ABS (non "+") defaults and got warped prints. The OP cited the satin build plate.

My hunch is that if the OP used Layerneer (or glue stick or hair spray) and repeated the print using the same temperatures, the print would have been flat and square and would have released easily after cooling.

Now having said all of that, I think it can all be summarized that higher build plate temperatures, in general, improve adhesion, with the risk of the prints sticking too well. Lower print temperatures result in an easier release, with the risk of warping and curl-up.

The OP appears to have a special case here, high plate temperature, satin build plate, possible nonstandard plastic formula, and warped/curled prints.

I have never used the satin build plate, but I have used (and I like) the Prusa textured build plate. My experience is, if anything, ABS tends to stick too well on the textured plate. Therefore I might suspect that build plate contamination and/or lack of an adhesion booster are possible suspects for the warping/curling issue.

Here is my overall list of suggested best practices for printing ABS on the Prusa:

1. Use an enclosure. If you don't have one, use the draft shield, available on both PS and Cura.

2. Let the printer preheat to ABS temperatures and stabilize for 15 minutes or so before launching the print.

3. Use something like Layerneer or glue stick primarily as a release agent.

4. When the print completes, let it cool to almost room temperature before attempting removal.

5. If the print refuses to release by flexing the build plate, put it in the refrigerator for 30 minutes or so. Let the ABS shrink a wee bit.

6. Avoid the temptation to use metal implements to remove an ABS print from a Prusa build plate! I learned the hard way on this!

RE:

Had reasonably good luck with ABS prints but mostly PLA lately. Don't have enclosure but use draft shield for ABS. Would not want to try anything long or flat but for little things it works well.

Never used anything but defaults.