no worries

Glad I could help. As you suggest, you should print the file as it is. temps and all. And see what you get.

one more thing

I am printing with hardened steel nozzle on that printer. I've never really adjusted my temps for that though. Just something to keep in mind.

great news

Let us know how the other pieces go!

Will do

I will upload e detailed pic once i am home, then start an identical mirrored print of this piece.

after that i am tempted to reduce the part a little and testing to print it with lower temps and another run without fans at 100%. I hope one of these two gives me the answer to why I had such problems.

I find it quite counterintuitive that higher temperature with more cooling leads to less warping 😀

i need to write down those findings for the future

keep in mind

The prusament pla profile is a bit higher than some but I do have the hardened steel nozzle on that printer so that has to be factored in. Interestingly though the Prusament PLA profile for printing on the MMU is in fact lower(204/200). This is mostly because when the filament is pulled from the extruder for tool changes the lower temp prevents the stringing on the filament tip. I believe most all the PLA profiles, even the generic one, are going to be 100% fan.

beautiful result

it's funny that all my reading, tinkering, calibrating and troubleshooting in the end got solved by using mostly standard settings.

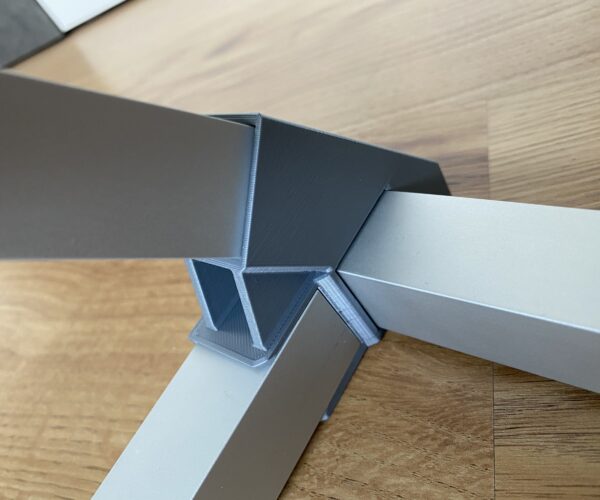

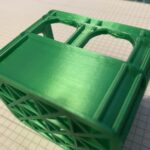

part is perfectly usable, the overhang, to me, looks almost as good as it gets. Most importantly the dimensions are all almost perfect for the intended use (spool holder). Currently printing the mirrored part of this with the same settings.

Pics of part and assembly:

nice

Over configuration is an easy trap to fall into. When I find myself having made a ton of changes, sometimes I go back to the start and try to make what I think are the actual required changes. My overhangs came out a bit better with the prusament though. It's possible the temp might be off by 5 or so degrees because of the steel nozzle on that printer. The brand of filament could be a factor also. But as you pointed out the part looks usable. Glad it's working for you though!

thank you for your help ssil2

i will use this thread to post some updates when i have time to print the overhanging bits with different settings (maybe improved)

sounds good

please do. if you have other pla to try that would be interesting to see as well.

digging this out again

So after being busy printing and doing things all around i wanted to go back to testing and tuning the overhang quality on my Prusa.

@ssill2 if you're still around you could help and try to interpret some results.

I printed everything in PLA and in my now completed enclosure (IKEA Lack). So no drafts and no excessive heat accumulation since no long prints.

- A temperature tower ranging from around 225 to 190 °C (observed measured temp for confirmation that the gcode script works)

- A bridging test at 210°C with bridging speeds of 20mms to 30mms and 40mms

- The previously failed battery crate, this time with stock settings and 100% fan all the time

Temp Tower:

It seems almost all temperature levels are of the same quality with random deviations. Strangely, i have light stringing on all levels too. One noticable thing though: On the backside of the print there was only one layer line on every level that did separate from the rest. Must have something to do with the cooling orientation perhaps? While i observed the print, the same curling behaviour appeared on each level. During the buildup of the overhang, the edge before the bridge ALWAYS curled up quite a lot. Each time making an audible thump when the nozzle connected with it, regardless of temperature. But i'm glad the part did adhere well and the nozzle temp softened up the material so that the print went through. What to take from this?

Bridging Test

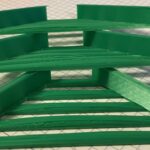

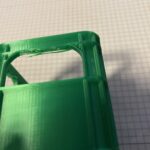

Only a small test having 3 pieces printed with 3 different speeds from 20 to 40 mm/s. All successfull with seemingly identical results. Don't know what to take from this other than that speed up to 40mm/s for bridges seems ok. What i don't like though is the quality of all these bridges. Maybe you can evaluate if there is a problem or if this is just to be exptected and OK. I can live with quality like this but maybe it can be improved by something i don't know yet.

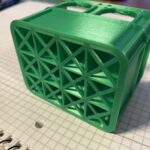

Battery Crate 2nd try

This time successfully with stock PLA settings and 100% fan throughout. Again, seeing the pictures of this print of other users, their bridges often have a much better quality than mine. The overall print quality i am very satisfied with, nothing to complain. Only the bridges have the same behaviour as always, curling up, thumping the nozzle, resulting in random, chaotic deformations in the transition area of the bridge. Again: Is this to be expected and is some post-correction after the print to get the overhangs to look nice normal? Or can something like this be printed without some of my disconnected strings and knots near the overhang?

That's it for the night 🙂 Thankful for any help!

so...

I would say that you'd probably want to slower the nozzle temp for bridges in this case. Maybe by like 5 deg. My supposition is that lowering the temp for bridged areas would allow less droop in the filament before it's cooled by the fan. I don't normally try to have bridges that long without putting a support of some kind under it. There is an option in the 2.4 version of the slicer, thick bridges, that you could possibly try. you might also try creating a copy of your .3mf with part the bridging part of your model so you can see how different settings affect the bridge without having to blow a bunch of filament and time for each iteration.

If you attach your .zipped .3mf here I could to do a small test print

sure

Here's the file, all stock settings except for bridges I think. Like you said, for some tests I could trim the bottom 60% of the model and make multiples of 'em with different temps for example.

But like the temp-tower showed, I am not sure that it will make a visible difference. hmm... 🤔 maybe it's my filament, or could it be the temperature sensor or someting really unexpected?

try

Both my printers are tied up at the moment, but I can give it a try tomorrow.

thx

thanks once again, i am not in hurry so you don't have to be either! I am just glad that someone like you so diligently helps me here.

trying

alright, I'm giving this a try now. I sunk the model about half way down so I wouldn't have to wait for the rest of it to print.

I'll let you know how it goes.

thanks once again, i am not in hurry so you don't have to be either! I am just glad that someone like you so diligently helps me here.

of course

it broke free from the satin sheet like 2 layers before it was going to do the bridge. At least it only takes about 35-40 min to get there again. Trying again on smooth plate with some adhesive. starting in the middle of the model just doesn't give it a ton of contact with the plate so I'm not terribly surprised lol

will let you know

yes of course

yes I have both versions of the slicer. I like to compare results between the two. I'm doing the first test print with default settings on 2.4 and then I'll use his file unmodified on 2.3.3. I personally like to see the differences, in particular dealing with supports. The supports on 2.4 are definitely better, and indeed it's one of the things prusa is touting as an improvement in 2.4. I agree that the results are to be expected with a bridge that long that's only 6 extrusions wide. I also think part of the the problem is that those narrow columns can move when the nozzle moves over top of them causing the bridge extrusion that was just laid down to bow just before they cool.

It's going to be awhile before 2.4 is ready, it might be best to help folks with their problems using the currently final version 2.3.3.3.3.3 whatever, the problem f0erster is having with bridges is model specific in this case. the tests shown using I (assume) default settings are exactly what I would expect.

Regards

Swiss_Cheese