Flex settings advice

I've printed my first Flex Benchy at 50% scale, on the MK3S+. The filament is Recreus FilaFlex 82A.

My first tries with PrusaSlicer's default FilaFlex40 failed, extrusion stopped after a few layers. After a few cold pulls (PETG was the previous filament) and release a little on the extruder wheels, I made my own filament settings from a post here, data from the filament maker, and some common sense.

# generated by PrusaSlicer 2.3.0+linux-x64 on 2021-02-27 at 08:39:54 UTC

bed_temperature = 0

bridge_fan_speed = 100

compatible_printers =

compatible_printers_condition = nozzle_diameter[0]>0.35 and printer_model!="MK2SMM" and printer_model!="MINI" and num_extruders==1 && ! (printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK3.*/ and single_extruder_multi_material)

compatible_prints =

compatible_prints_condition =

cooling = 1

disable_fan_first_layers = 2

end_filament_gcode = "; Filament-specific end gcode"

extrusion_multiplier = 1.05

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #008000

filament_cooling_final_speed = 3.4

filament_cooling_initial_speed = 2.2

filament_cooling_moves = 4

filament_cost = 34.99

filament_density = 1.22

filament_deretract_speed = 20

filament_diameter = 1.75

filament_load_time = 0

filament_loading_speed = 28

filament_loading_speed_start = 3

filament_max_volumetric_speed = 2.5

filament_minimal_purge_on_wipe_tower = 15

filament_notes = ""

filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

filament_retract_before_travel = 3

filament_retract_before_wipe = nil

filament_retract_layer_change = nil

filament_retract_length = 2

filament_retract_lift = 0

filament_retract_lift_above = nil

filament_retract_lift_below = nil

filament_retract_restart_extra = nil

filament_retract_speed = 20

filament_settings_id = ""

filament_soluble = 0

filament_spool_weight = 0

filament_toolchange_delay = 0

filament_type = FLEX

filament_unload_time = 0

filament_unloading_speed = 90

filament_unloading_speed_start = 100

filament_vendor = Filatech

filament_wipe = 0

first_layer_bed_temperature = 0

first_layer_temperature = 230

full_fan_speed_layer = 6

inherits = Filatech FilaFlex40

max_fan_speed = 100

min_fan_speed = 100

min_print_speed = 15

slowdown_below_layer_time = 5

start_filament_gcode = "M900 K0"

temperature = 230

The most important thing, I think, was to reduce retraction speed. I did that because the extruder behaved like this as soon as infill pattern started:

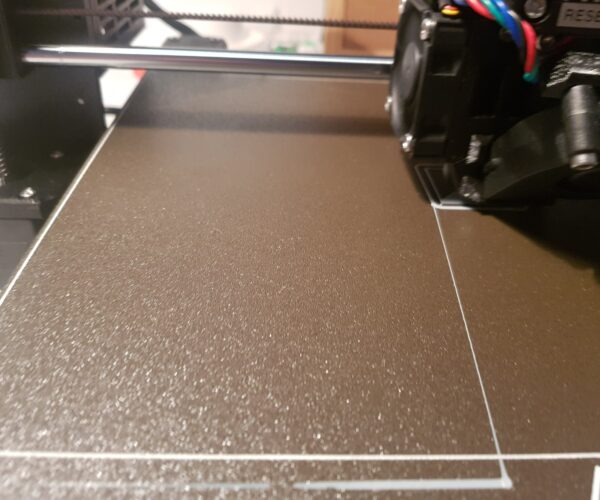

With these settings, here is my 50 % Benchy:

Not too bad for the size and flex, but I'd like to do better.

Something that surprised me, and I think it might be a useful smoking gun for future tweaking, is the delay in the "starting bottom left line" (it doesn't come out right away), and the fact that there is a line between this and the start of the model. See:

Something tells me I should look into Linear Advance and K.

Something else I should look into first?

RE: Flex settings advice

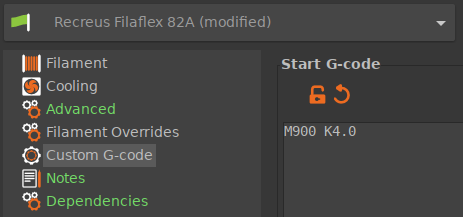

So after doing the K-factor calibration with the Marlin pattern script, I chose a K-factor of 4.0 (yeah, that's a lot, but I figure with flex, why not). Although I'm not sure about all the parameters.

I also lowered speeds quite much:

The hull is much better (might depend on first layer adhesion, I think). I got more stringing though, so I guess the K-factor was a little too much at 4.0. Or too little? To be honest, the K pattern was not very clear to decipher, it looked like the "fast" area of lines were to thin as a whole. Maybe I should lower speed even more? What would you do?