First layer and curves improvement

Hello everyone!

I'm printing these parts using Polymaker Panchroma PLA and facing two issues. The first layer has gaps that I want to fill, I tried increasing the overlap to 25%, and still the issue remains. The other issue is this weird thing happening at the curves (I don't know what it's called, see the image below), I tried adding supports and lowering temps on those layers, yet it hasn't improved (the only thing that previously improved it was a shorter layer height, it was way worse before).

Please help me to improve it.

RE: First layer and curves improvement

Well your first layer is due to the fact you don't have your live z correctly dialled in. You don't adjust slicing settings, you adjust the Live Z offset on the printer to get a first layer where all the filament is squished together. Yours is too high and needs making more negative.

When a live z is adjusted properly you get a surface that picks up every little ding and scratch on your print bed but is otherwise nice and smooth. Like this -

The other issue of the curves you are going to struggle to do anything with beyond what you already have done. At least printing in that orientation. Its a fundamental problem of printing in layers. Those angles are basically close to a overhang and so not supported by most of the layer below. That's why decreasing your layer height helped, when sliced thinner more of the layer above is on top of the layer preceding. When you slice always check the preview and learn what all the colour coding means. This can help you spot potential problem areas before printing.

As you have seen that supports are of limited use here as you have to leave a z gap or they fuse to the part. This leads to the slight sagging. So unless you go multi-material with a zero gap and use a soluble or non sticking filament as the interface layer you are limited in what can be achieved.

Also supports don't really work when the area to be supported is close to the bed as often due to the z gap and the XY support gap theres not actually room under a part at lower layers to actually fit any support in.

RE: First layer and curves improvement

Thank you for your reply. As I don’t have an mmu, I cannot use the soluble support as you suggested. Would printing in a different orientation lead to a better result? If so, which face should be on the plate?

RE: First layer and curves improvement

Your first layer looks like the Extruder is too high (Live Z too small a negative number at the moment)

the other issue looks like the filament is drooping on overhangs

what layer height are you printing at?

is the droop area facing away from the Part fan nozzle?

turning the part around may help.

a lower layer height may help.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer and curves improvement

I am printing at 0.1mm using a 0.4mm nozzle. The droop area is parallel to the fan.

RE: First layer and curves improvement

0.1mm should be ok. Can you turn the model so that the affected area faces the fan and try again?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer and curves improvement

My bad, I double checked and it actually is facing the fan. Should I try slowing it down at overhangs while lowering the temp?

RE: First layer and curves improvement

both are possibilities.

give them a try and see what happens

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE:

This is the first layer after adjusting the live z, at 25% overflow. Is this the best it's going to be or can it be improved? Also, the print started lifting at the overhang part, is it due to the lower speed (I enabled dynamic overhang speeds, and lowered the temp at the layers where the overhang was to 195 from 204, starting from layer 3)

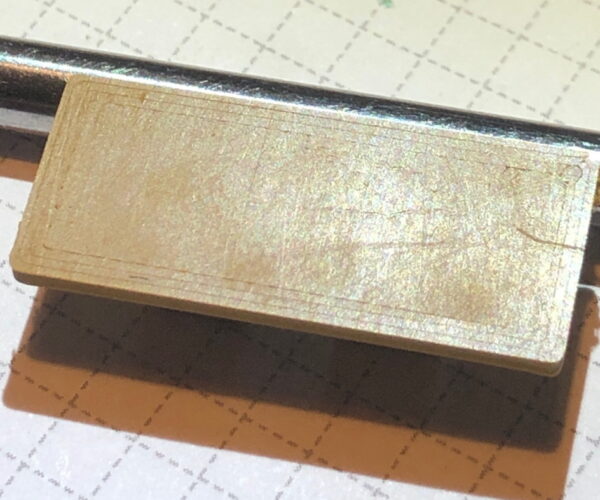

RE: First layer and curves improvement

This is my first layer on a smooth Buildplate with holographic surface on Mk3S

Live Z settings are unique to every printer, the image above shows both sides of a first layer print, on my Mk3 on that particular day the actual numbers are not particularly inportant, but the difference between the numbers indicate that small changes can make significant differences to surface finish,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer and curves improvement

I'm still not sure how to fill those gaps, is it because the part is small or due to settings?

RE:

the first layer quality is governed by the ammount of squish between the nozzle and the build plate

on the Mk3 series printers, this is a factor of Live Z

the Prusa first layer calibration tool ism in my opinion, quite difficult to use.

There are many better options

ont, albeit aged, is "Life adjust 'Z' My Way" by Jeff Jordan

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK