Constant jamming, out of ideas for what to check

I've been battling under extrusion lately on one of my printers but I have run out of ideas about why. List below on what I have checked but what should I check next? it's a stock MK3s with a .4mm CHT nozzle and silicone sock

-Cold pulls are clean

-filament feeds easily by hand when fed

-took hot end out, cleaned all gears, replaced PTFE since it was beat up

-after clean and rebuild it printed 2x 60mm Z height squares fine but started to under extrude 2 min into an actual print

-Filament settings and temps and files are fine on other mk3s

RE: Constant jamming, out of ideas for what to check

I tested the idler tension by loosening and then cranking the screw way down and when cranked way down it seems to have helped but i had limited time to test.

when it was under extruding pushing down on the filament feeding in and “helping” it also corrected the issue

Which filament?

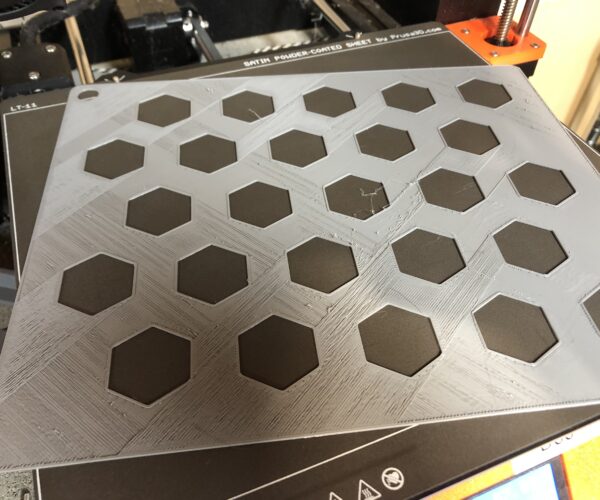

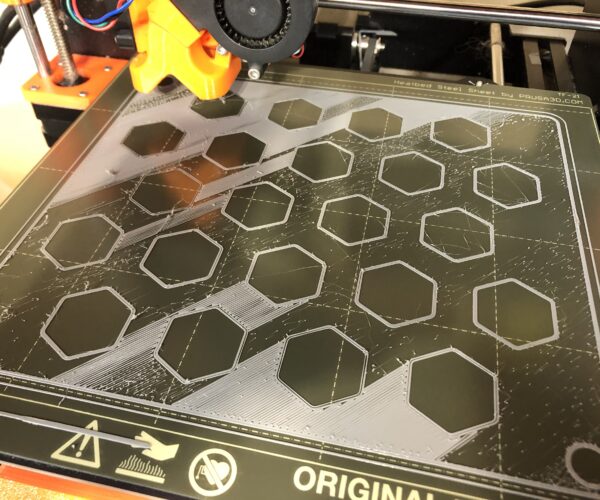

Please post a picture of a failed print illustrating the issue.

Cheerio,

RE: Constant jamming, out of ideas for what to check

-took hot end out, cleaned all gears, replaced PTFE since it was beat up

This might be the source of your problem. Did you replace the PTFE with the right one? Where did you get it from? It's not that hard to order the wrong one in the prusa shop(I did that some time ago) they differ between models even MK3S to MK3S+. They need to be the exact right length, ID and chamfer to work properly. I'd double check the PTFE.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Constant jamming, out of ideas for what to check

its the correct one, mostly because I put a MK3s+ one in from a spares bag and then realized once it was all put back together so I had to take it apart again and use a correct MK3s one

I had a print with a ton of extra idler tension and printed at 230 work (this filament prints at 215/210 on other mk3s printers). going to test each of those solutions individually to find if one solves it on its own. Hopefully it's the idler tension which may mean the spring as set or something because I don't want to replace the thermistor which is what the 230 would indicate to me

It does look like a filament path issue, if you are certain of your PTFE tube and cold pulls are clean then try slacking off the idler completely and check it turns freely.

Cheerio,

RE: Constant jamming, out of ideas for what to check

it spins fine, loosening way off had no change in the issue on a print

material is just standard PLA

it spins fine,

You feel no roughness when you turn it with a fingertip?

Cheerio,

RE: Constant jamming, out of ideas for what to check

nope, I made sure it was all good when I took the hot end apart for cleaning. Spins with no effort

Have you been printing abrasive filaments? Examine the Bondtech gripper teeth with a magnifying glass, it's just possible they may have worn too much to grip.

Cheerio,

RE: Constant jamming, out of ideas for what to check

Just standard PLA through this printer. I can open it up and take a closer look at the teeth, seemed fine when I cleaned them

out but I didn’t compare to a newer printer’s

RE: Constant jamming, out of ideas for what to check

This might be a stretch but do you have a stock brass E3D nozzle to swap back in?

Just a thought…

Cheers

RE: Constant jamming, out of ideas for what to check

it was doing it with the stock nozzle as well, that is why the CHT went in

RE: Constant jamming, out of ideas for what to check

got a few prints out with the standard temps but high tension. Then it stopped again.

this time I checked the idler tension and the screw had back out.... so that is a new thing I have never seen before. I don't see a new spring in my bags, does anyone know the stock specs?