Hotend Leaking | Stuck after 5 attempts of fixing

Hi all, I have had my mk3s+ for a little over 2 years, and recently I had to disassemble to hotend to remove some filament jamming the PTFE tubing, I reassembled it according to E3D V6 instructions but I began to get leaking. VERY LONG story short, I disassembled the hotend again, cleaned the heat block, nozzle, and the heat break with acetone, and assembled it again, taking a lot of care to ensure the nozzle was not touching the heat block and that the heat break and nozzle were firmly in contact. At this point, I have disassembled and reassembled the hotend 4 times each time getting leaking afterward and each time I have decreased the distance between the nozzle and block to the point where now I don't want to go any closer for fear of them touching. I would just buy a fully assembled hotend, but shop prusa is out of stock so I figured I'd turn here for any last-ditch solutions because worst case scenario I just wait and replace the whole thing. I have read the hundreds of other posts about this exact same issue, watched the videos about the scaled-up model, and have really tried to follow the E3D instructions as precisely as possible so I am really getting fed up with this.

RE: Hotend Leaking | Stuck after 5 attempts of fixing

The nozzle needs to be tight

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Hotend Leaking | Stuck after 5 attempts of fixing

all I have for you is a little trick, not normally needed per se, but always better.

the gasketless, high pressure, all metal joint benefits from smooth, square, mating surfaces.

I introduce new nozzles and the break itself to a vblack and a fine stone. just to get burrs and machining marks off.

do a cold assemble where you can see all the bits clearly, and painlessly

only other odd ball would be the block threads forcing a misalign when torking, but that would be very 3 legged unicorn

Hi all, I have had my mk3s+ for a little over 2 years, and recently I had to disassemble to hotend to remove some filament jamming the PTFE tubing, I reassembled it according to E3D V6 instructions but I began to get leaking. VERY LONG story short, I disassembled the hotend again, cleaned the heat block, nozzle, and the heat break with acetone, and assembled it again, taking a lot of care to ensure the nozzle was not touching the heat block and that the heat break and nozzle were firmly in contact. At this point, I have disassembled and reassembled the hotend 4 times each time getting leaking afterward and each time I have decreased the distance between the nozzle and block to the point where now I don't want to go any closer for fear of them touching. I would just buy a fully assembled hotend, but shop prusa is out of stock so I figured I'd turn here for any last-ditch solutions because worst case scenario I just wait and replace the whole thing. I have read the hundreds of other posts about this exact same issue, watched the videos about the scaled-up model, and have really tried to follow the E3D instructions as precisely as possible so I am really getting fed up with this.

RE: Hotend Leaking | Stuck after 5 attempts of fixing

I have only ever been told that the nozzle should be tight against the heat break, but NOT touching the heat block. Is this what you mean?

RE: Hotend Leaking | Stuck after 5 attempts of fixing

Never heard where nozzle shouldn't touch heatblock do you know why

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Hotend Leaking | Stuck after 5 attempts of fixing

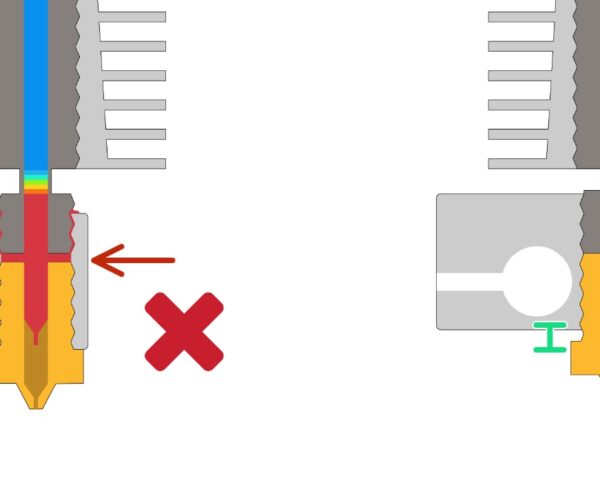

The nozzle needs to be tight to the heatbreak inside the heat block but, a gap must be present between the base of the nozzle and the heat block. Final tightening must be done with the hot end at 280c. If there is no gap, the nozzle is likely not seated against the heatbreak and you will get leaking above the heat block and below the heat sink. See pic below and link:

https://help.prusa3d.com/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

Cheers

RE: Hotend Leaking | Stuck after 5 attempts of fixing

No I do not, I assume because it will help to preserve the life of the nozzle, but I really don't see any real detriments.