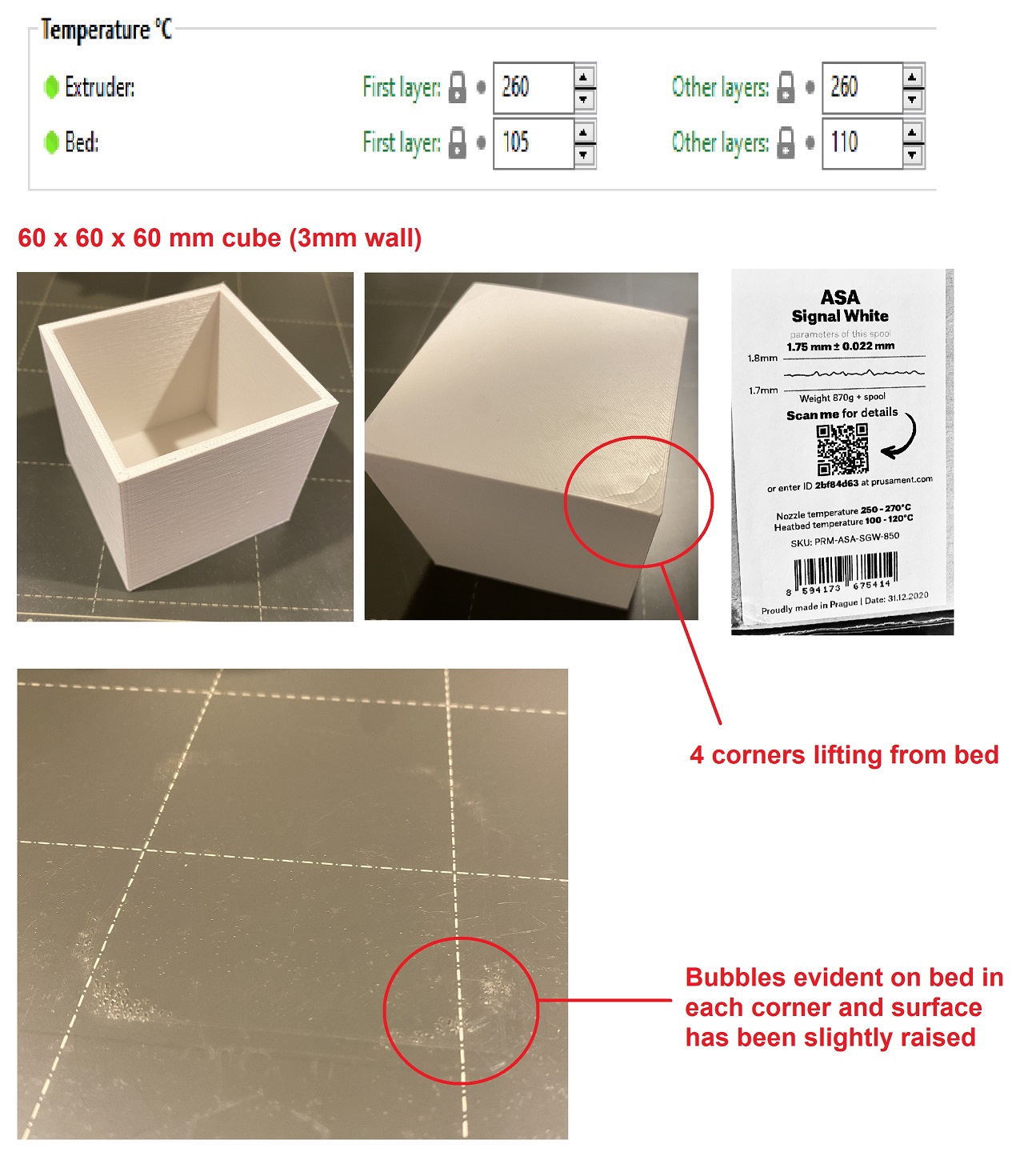

ASA warpage damaging the bed

This test cube prints very well in PLA and PET (used for dimensional stability evaluation).

However, in ASA the corners are lifting and this has caused local deformation of the bed (raised surface with bubbles).

Default conditions for Prusament ASA have been used.

Appreciate thoughts on improving this condition (such as brim). I assume the corners are retaining heat and this has softened the bed surface - have others experienced this?

Normal. Use a release/bonding agent

What you are observing is normal. Assume you are not using an enclosure (to print ASA you should). Try brim, and definitely add some sort of bonding agent - either V05 Hairspray (about ten coats, dry between coats) or Lumineer or Bed Weld or something like that. ASA is not PLA. Welcome to the big leagues.

Your picture also shows your bed is not clean, that first layer failed from Live Z being off or a fingerprint in that corner or something. Clean bed with hot soapy water, then only handle it by the edges. Enable 7x7 bed mesh leveling.

But for ABS or ASA, you have to use a release agent or your PEI will become damaged. Same thing happens with PETG, but for PETG you can use windex blue for the release agent.

ASA considerations

Good to know. No, not using an enclosure or release agent. The bed was cleaned by wiping with 95% ethanol (rubbing alcohol). I should clarify that all four corners fail equally and the 'lifting' doesn't occur until perhaps 2mm of Z build - the first layers look good and are attached.

Adding a brim and increasing fan speed to 50 made a marginal improvement.

For my education, adding release agent seems counter-intuitive - isn't more adhesion desirable to hold the corners to the bed, rather than adding a coating that provides less? Perhaps I'm misunderstanding: are you recommending Windex first on the bed (for release), then layers of hairspray (for bonding)?

No.

Windex is for PETG. Layerneer, bed mud, etc - are for printing high temps. V05 is the release agent for high temp plastics - you want it to release after the print. Release of the high temp plastics need the bed to be 100% cooled down - don't try and pop them off till they are cool.

IPA isn't a good bed cleaner - it is a quick degreaser, that's about it. But it won't remove the grease that is there, it more spreads it around until it is too much grease. Seriously - take your print bed to the sink, run some hot water, add some odorless dish soap (you don't want to be coating your plate with oils from perfumes) and scrub it with a scrubbie (not a metal one). Get the grease off. Then use a bonding agent where you plan on printing, then for ASA or AbS you really need to use an enclosure and ventilate it very well (poison gasses).

Finally, adjust your designs to prevent warping. A PLA model may not print at all in ASA or ABS - due to the cooling issues that cause warping. Cut slots in your long horizontals ... break the long runs up or orient it so there are no long runs to warp. It takes some engineering thinking to switch to high temp materials and a deeper understanding of what cause warping before you can get that aha.