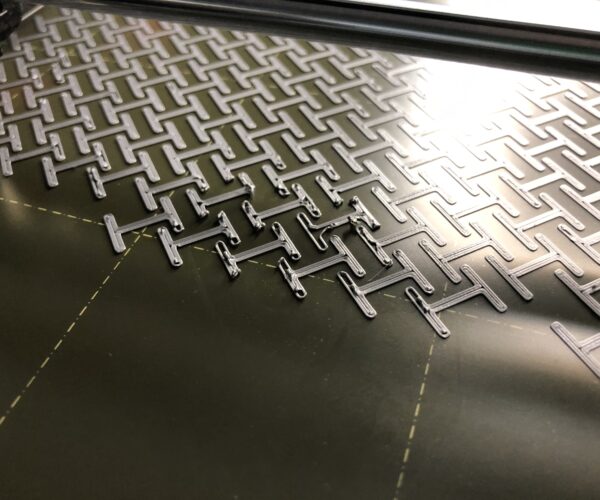

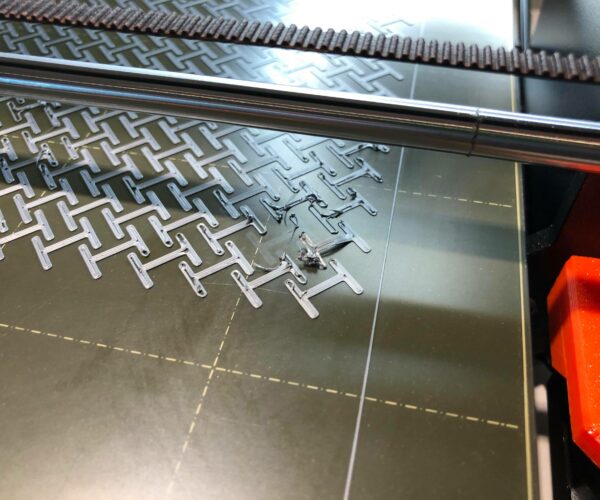

3D Printed Fabric, doesn't print well.

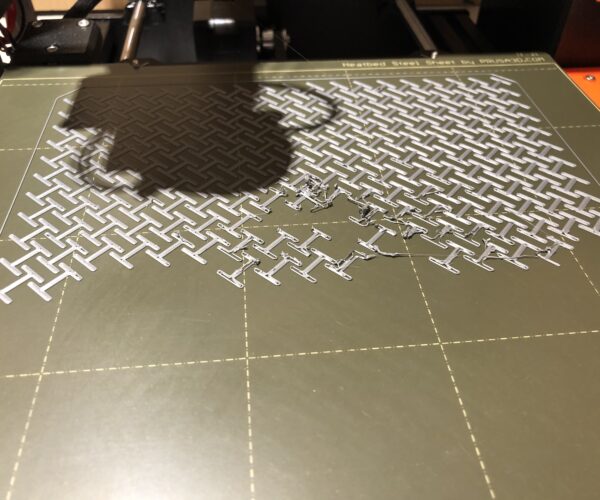

I tried printing the Printable Fabric, designed by Flowalistik. It Prints quite well, except for the places in the photos where it failed. I cleaned the sheet with 93% Alcohol before printing. The file was sliced in PrusaSlicer 0.2mm layer height and 0% infill. I have also tried using the mesh bed level 7x7. Can it be the live z? Any ideas on how I might fix this?

RE: 3D Printed Fabric, doesn't print well.

looking at that your live z isn't anywhere near far enough down. Those lines need to be squished more. Have you used the Jeff Jordan Life Adjust method described on the forum to calibrate your live z ?, its much easier than the built in method.

RE: 3D Printed Fabric, doesn't print well.

@neophyl

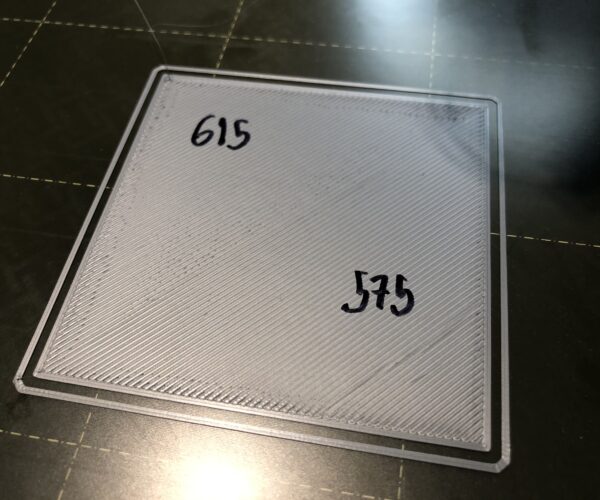

Okay, I will try lowering it, how much do you think it will need? Currently at -575. Haven't tried the Jeff Jordan method, where can i find it?

RE: 3D Printed Fabric, doesn't print well.

You can go down to -2000 in software but if you have set your pinda height anywhere near right it is generally between -500 to -1500.

The Life Adjust thread is here https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Its a big thread though but you only need the stuff at the start.

The basic theory is simple enough though. You print a single layer high square (or circle) roughly 75mm in size. As its printing you can adjust your live z height value until the lines squish together and theres no gap between them and its an unbroken sheet of plastic. If you go slightly too low you get ripples in the surface so you back off 5 or 10. When peeled up after the print you shouldnt be able to separate the lines. It doesnt take long and usually 1 or 2 passes is all that's needed. You can use the files in the thread or just right click on the plater in slicer 2.2.0 and add part, cube and then unlock the scale and make it 0.2 high and 75x75mm in X&Y to create your 'test coupon' shape.

Also when it comes to cleaning your bed for adhesion then plain dish soap such as Dawn/Fairy and copious amounts of hot water to rinse away the grease works much better than IPA. Just remember to only touch the edges to stop finger oils getting on the sheet after you have washed it.

RE: 3D Printed Fabric, doesn't print well.

looking pretty good. When you peel it up try to separate the lines. If you can then its not quite enough 🙂 If its a sheet and its smooth with no ripples then you have your value for that sheet with that material type.

You sometimes need to tweak the value for different materials for example when switching between PLA and PETG. and of course any time you swap nozzles or steel sheet you have to recalibarate the live z value again.

RE: 3D Printed Fabric, doesn't print well.

@neophyl

Yes! Thank You for the help:)

RE: 3D Printed Fabric, doesn't print well.

Also check if your nozzle is not worn down.

If the nozzle is worn down, printing will get less precise.

RE: 3D Printed Fabric, doesn't print well.

Don't bother with the IPA clean. Take your build plate to the sink and using plain unscented dish soap/ washing up liquid (something like Fairy /Dawn) scrub the bed with a clean paper towel and the soap. The rinse it off with LOTS of HOT water. Being careful to only touch the sides of the sheet once you have washed it to stop your skin oils getting back onto the now clean sheet. Dry it off with more clean paper towels and then stick it on your bed at 90c for a few minutes to bake it dry and remove the last of any moisture to prevent rust.

The dish soap and hot water are far more effective at removing grease and oils than IPA. Alcohol dissolves the grease and spreads it in a thinner layer , so unless you have gallons of the stuff to rinse with it doesn't work as well. Bonus is that at this point its hard to get anyway so the fact you don't need it is a plus.

Once cleaned this way I then never handle the sheet with my hands if I can avoid it, and its easy to see where your fingers have touched. Even if I print solid for a week, I only generally have to clean the sheet once every couple of weeks sometimes longer.