Problems printing any long vertical pins/tubes/posts

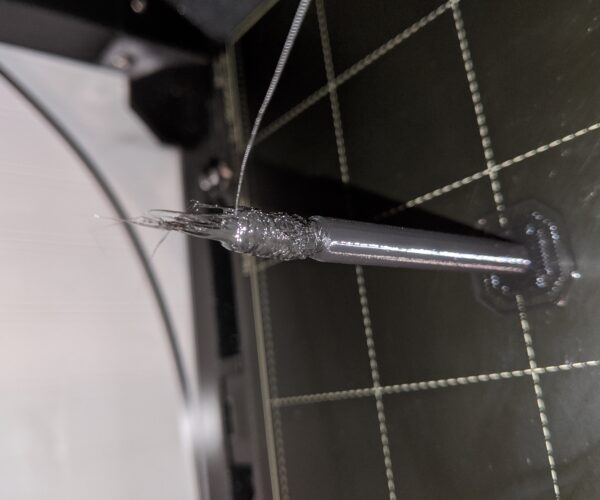

I have a Prusa MK3 and I am having a lot of problems printing anything that is a long, narrow vertical item (pins, tubes, posts, etc). For example:

https://www.prusaprinters.org/prints/7630

This is a 7.8mm x 100mm cylinder/shaft. I tried printing 16 at once, then 4, then just 1. Each time it prints partway then at some point it is as if the head collides with the print or the extruded filament gets stuck to one of the shafts (not sure as I haven't observed it as it happens). Either way the result is that the shaft in question is knocked over. If using a raft, the raft detaches under that shaft so the shaft becomes misaligned. On the next pass the head doesn't make proper contact (since the shaft isn't where it is supposed to be) so it begins to make a mess. If printing multiples, this usually results in the bad shaft knocking into others nearby and pushing them out of alignment eventually ruining the entire print.

Any ideas of the parameters I should be trying to stabilize these types of prints?

RE: Problems printing any long vertical pins/tubes/posts

I would put a small brace between rods so that they each stabilise the adjacent one.

then trim them off later

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Problems printing any long vertical pins/tubes/posts

That bottom photo is definitely wrong. It looks like there's too much 'lean' in some of the shafts, indicating to me that it's not at the correct X position for some of the layers. Loose hardware? Also lots of blobbing. Over extrusion? I'm not sure. Those look like they should be straightforward to print.

For the project I am working on, I've printed several spacers with a 1.9mm radius vertical shaft rising 40mm with the default 20mm generic PLA parameters in Prusaslicer. I use a default brim.

RE: Problems printing any long vertical pins/tubes/posts

Check the whole printer for loose parts, also move the extruder and see if it is loose.

Check belts.

Do a new z-calibration, especially if you change someting.

Check if filament is not to thick, if it is then it will hit the nozzle because of to much filament. You could also search for extrusion test.

Print with a good temperature, a temp tower test could help, if temperature is not good, the filament could be pulled up, then the nozzle will hit this.

Do a first layer test, if you are to low, the higher up in model you can get problems, a good first layer will stick the best, also clean bed with dish soap , for better sticking.

And of course slow down wen is does not work.

RE: Problems printing any long vertical pins/tubes/posts

What is the first layer , is this a raft?

RE: Problems printing any long vertical pins/tubes/posts

In de 3e picture I see layer that has open holes in it, the first layer is not good or you are using a raft.

Use the normal settings, and use distance from skirt to 0 and brim width 8, the model will stick good.

As mentioned above you could make a small bridge between model, so they are stronger.

But if you want to make the model stronger, print in horizontal plane.

RE: Problems printing any long vertical pins/tubes/posts

To answer some of the questions, yes, I was using a raft to give more stability vs just the base of the rod.

I believe I solved the problem however. I was looking at another forum post and remembered something. Shortly after I got the printer, I broke the blower shroud. So I downloaded the spare part from Prusa and printed another one. However, the only material I had on hand was PLA so the shroud tended to bend and warp when the hotend was at full temperature. To make matters worse, the rods I was trying to print were PETG, so were being printed significantly hotter than PLA.

I printed a new fan shroud I found in the remixes here under Prints. This shroud I printed with PETG (I don't have ABS right n0w). After installing the new shroud I was able to successfully complete 2 full prints of the rods.

RE: Problems printing any long vertical pins/tubes/posts

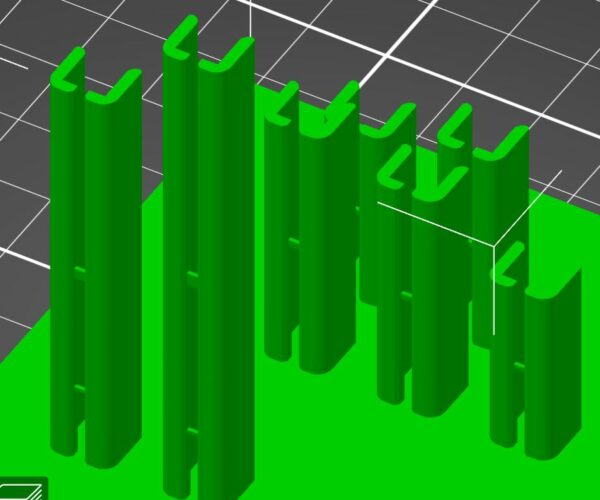

Here's a shot of the spacers I referred to in the previous post. These were done with the .3mm 'draft' settings using whatever filament happened to be loaded, in this case the Filament PM equivalent of the Prusa (ment?) that came with the machine.

Your MK3 should easily be able to do better than the items in this photo with some attention to detail.

RE: Problems printing any long vertical pins/tubes/posts

Did you add those braces in Prusaslicer? If so, can you please share how you accomplished it? Thanks.