What does mesh bed leveling actually do?

I've been trying to wrap my head around what mesh bed leveling actually does. I thought it is supposed to automatically correct for tilt and undulations in the bed. Yet we still have a bed level correction setting, which I have found is necessary to employ to get good 1st layers for large or highly nested prints. (my "dialed in" bed corrections are L:-20, R: 50, Ft:15, Rr:5).

I run a 7x7 mesh, so I would have thought that is plenty of points for the printer to accurately map out the print bed. However, my results from the 1 layer print in this article https://help.prusa3d.com/en/article/bed-level-correction_2267 told me otherwise. How exactly, do mesh bed leveling and bed level correction work, and how do they work together?

RE: What does mesh bed leveling actually do?

7x7 mesh bed leveling will correct for minor variations, particularly when you remove and replace the spring steel print surface. The bed level correction is used when your bed has irregularities mesh bed leveling can't correct for. If you find your bed is badly deformed on a new printer, take a picture of a straightedge laid along it with a light shining from behind. If a lot of light shows through, that demonstrates the warp. Contact Prusa online support via chat when logged into the estore.

tl;dr - Use manual bed level correction (or things like the nyloc mod) when 7x7 mesh bed leveling isn't sufficient. Otherwise, don't worry about it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: What does mesh bed leveling actually do?

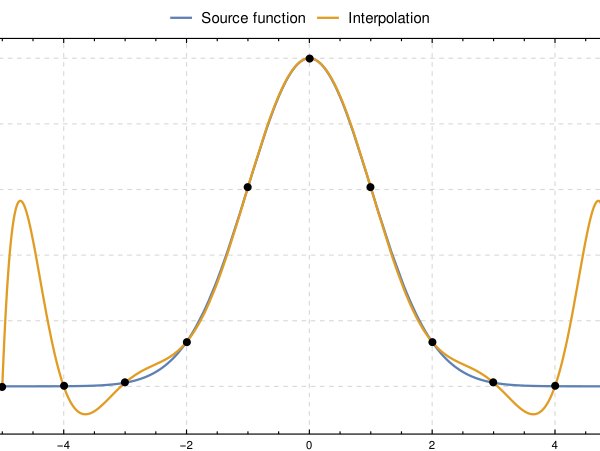

Due to the nature of the interpolation being used, there are asymptotic points that can really mess with particular leveling results. If the average measured point data is not near the true mean, the end points (and even internal interpolated points) can be dramatically erroneous. A user has no way of knowing when this happens. So you get these "apparently" high or low edges that really aren't there; and the only way to deal with it is bed correction.

At least, that's how I've analyzed the issue; ymmv.

Here's an example of bad things happening, what is important are the end points, and what the printer firmware does outside these points. When the interpolation is working on some surfaces, the process "fails" and adds "extreme correction" to fit the measurements. And when the position is outside the measured area, the process breaks down and can exacerbate actual bed shape errors.

It could be fixed by increasing the size of the array being interpolated and forcing the edges to match the linear slope of the measurements, this would constrain the Lagrangian interp to rational values.