RE: Prusa i3 MK3S - New Nozzle X and print quality

https://e3d-online.dozuki.com/Wiki/Nozzle_X_warranty sorry forgot to add it...

Hmm. They say cold pulls might damage the internal coating, but coating isn't covered by warranty. They also mention internal coating is expected to wear with abrasives. They're just saying both internal and external coating isn't covered by warranty. I don't think I'd let that stop me from doing cold pulls if I had a jam.

RE: Prusa i3 MK3S - New Nozzle X and print quality

Yeah you are right, I did misinterpreted what they are saying about whats covered by waranty and what may damage coating your absolutely right.

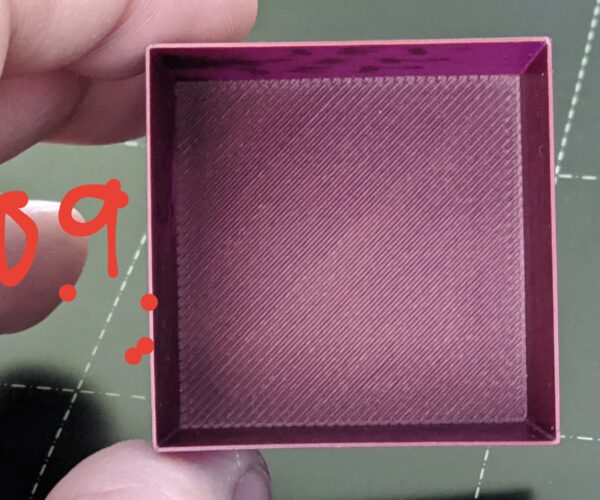

I did a PID calibration . Then I printed the cube I Measure 0.45 from a 0.150 layer height 40x40x40 cube. If I measure in corner it thicken a little I have a few read around 0.46 I will bring the cube work tomorrow to use a Micrometer instead of my galiper (its a mitutoyo but its still not a micron tool ;o) Its rated +/- 0.02mm i will try another calibration print. As I see some 0.46 I will try for fun as if I have 0.46+0.46+0.45/3 = 0.45666 : 0.45/0.45666 = 0,9854 looking this way its still a diference I guess...

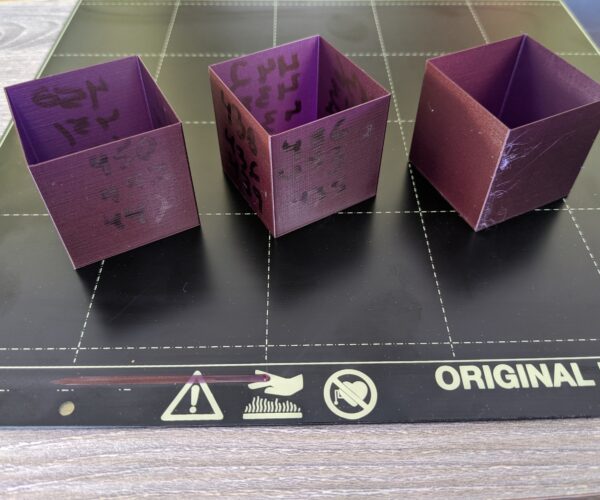

The grey print is the one that came with my prusa (not prusament i think) and the brown/red is prusament both slice with prusament profile.

THANK for the tip I was not sure where to start... Ill print the same parts to verify the result!

RE: Prusa i3 MK3S - New Nozzle X and print quality

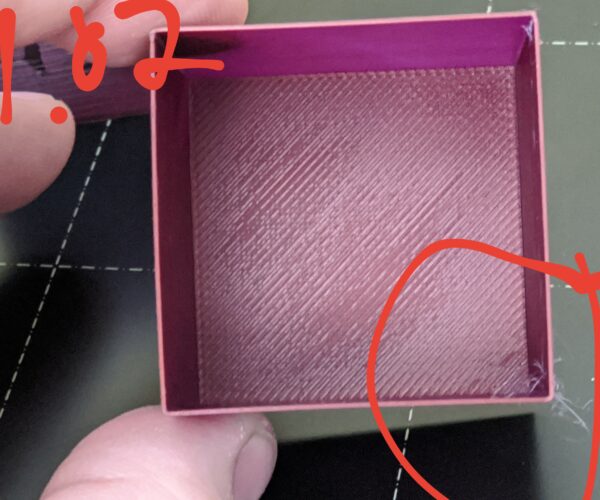

I printed a cube with the correction and check my measurement at work with a micrometer. After correction i was more in the unde side with 0.438 of average... so printed another with that factor of 1.0297. I am waiting for a micrometer i order to double check measurement but it has air... i think i will try to print some part that were bad again with 1 extrusion factor...

I Think the temp was a big part of the issue ( I hope ;o) And previous trouble were bad cheap nozzle...

I will still install the heat break later when all is perfect... to be continue...

Thank again @bobstro !!!

RE: Prusa i3 MK3S - New Nozzle X and print quality

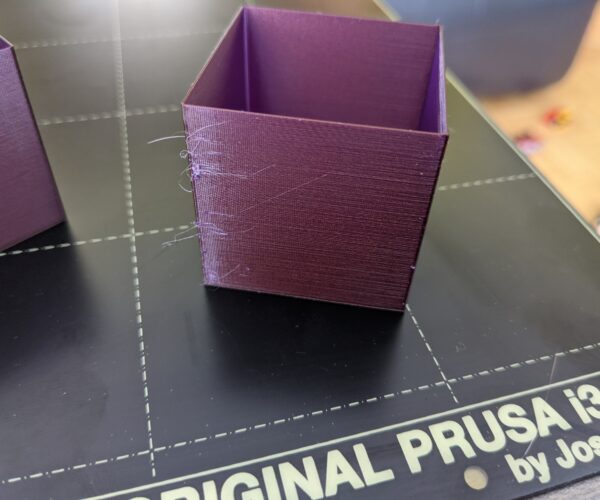

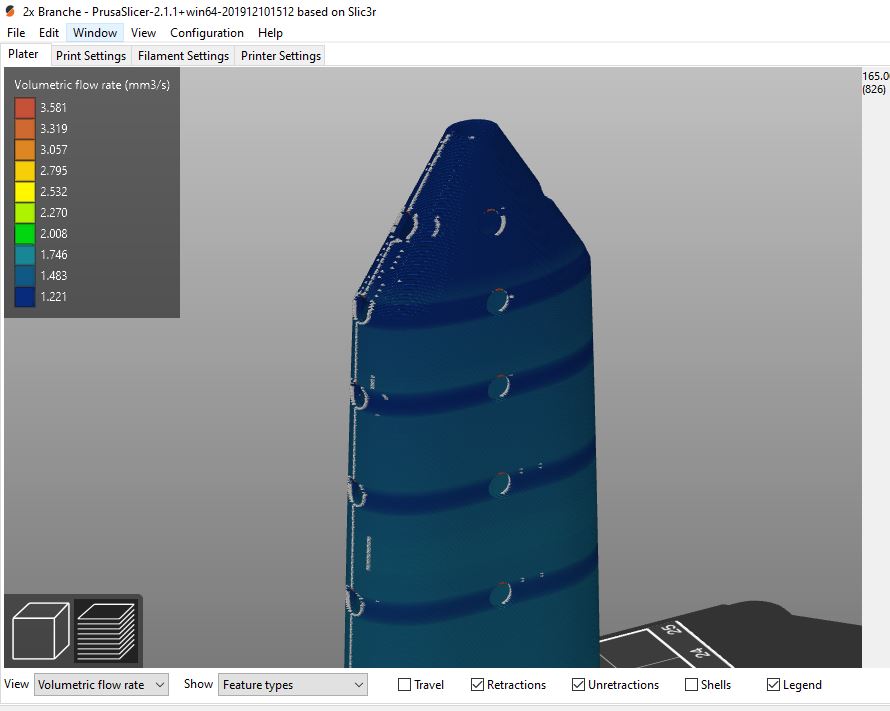

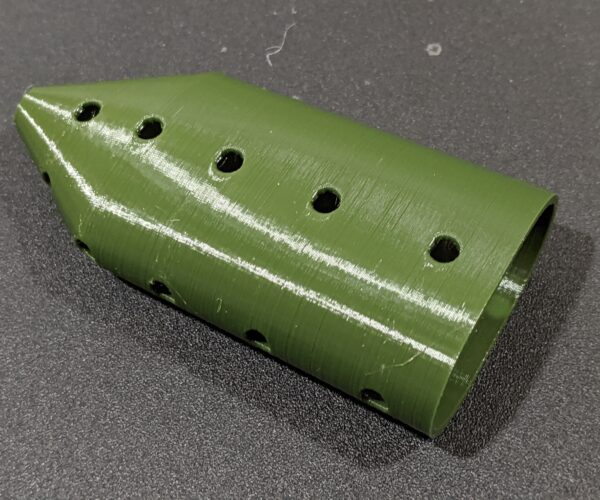

Still have those line were the hole are locate and the seem is still verry visible.. Any idea what can i do to help those. I will try to print from the outside to the inside to try. here a view if I print one at a time I can see that the defect is related to the flow the diference between the 2 images is 0.2 quality vs 0.2 speed profile... Green and Red are Prusament grey is a spool form Prusa...

RE: Prusa i3 MK3S - New Nozzle X and print quality

You can read through a very long thread on this topic here. As you see in your preview, the flow rate changes on the layers with holes. This is caused by the print head reversing direction and thus speed. Acceleration and jerk come into play. The best solution I've found for these issues is:

- Slow down external perimeter speeds. I use 25mm/s.

- Add an external perimeter if possible (may not do much for a hollow part)

- It's also worth calibrating your extrusion multiplier for each filament to avoid any over-extrusion. The smallest amount of over-extrusion will accumulate on solid layers and possibly show as a bulge or distortion on external layers.

- Edit: If this is a part you designed yourself, make the walls a bit thicker if possible.

If you'd care to save your project off in a 3MF file, zip it and upload it here, we may be able to make more suggestions.

RE: Prusa i3 MK3S - New Nozzle X and print quality

I will take a look on the thread i will slice the next batch with the reduce speed. First time I printed this part it was 2 wall thick I added a third wall and your right it improve... Those fillament have been calibrate but the correction is less then 0.002 so i end up not bother because when I print with the correction I usually see another correction needed in the reverse direction of around the same difference 0.002. So as i see i am bouncing around 1 from one cube at 0.998 to another demanding 0.00312 I decided those were close enought at 1. Is it what you would tolerate ?

thanks for the QUICK answer ! :O)

here the .3mf if you want to take a look! I want to share the project if it can ne of use to someone but if i can figure this out a little to improve the look I would like that :O) thanks

https://drive.google.com/file/d/1W1tXdB1pY4YjQuBQqviCsN5fkViVoNnP/view?usp=sharing

https://drive.google.com/file/d/1N0SVg13TnVTwh-lwgiILidMkiYZ0z-Yk/view?usp=sharing

RE: Prusa i3 MK3S - New Nozzle X and print quality

I extracted the part from your print and cut it down for a quicker print. Here's what I'm getting with a 0.5mm plain brass nozzle (I'm experimenting with this size), 3 external perimeters @ 25mm/s and a calibrated filament:

RE: Prusa i3 MK3S - New Nozzle X and print quality

Ho cool for the trial! is this a prusament green?

It look like the thicker wall could help like you suggested. I did realize something looking in the parameter. In the minimum number of perimeter section they give example of wall thickness different then what i did use to designing the part. I build my solid at 1.35mm of wall 0.45 x 3=1.350mm... But the slicer is suggesting these lines thickness for 0.2 height:

2 lines = 0.86mm/2=0.43 , 4=1.67/4= 0.4175 , 6 lines = 2.49/6=0.415

I rebuild my model with this thickness: 1.245 /3 = 0.415 per lines and it print without the defect allign with the Hole.

In the slicer you can see new and old look like its making 2 lines inside... or is it to show it overextrude ?

I tried Perimeter out first, no defect from the hole but a lot of wierd defect on the part.

I had another Perimeter 4 x 0.4175 = 1.67mm and it look almost flawless from the test print I will print a pair now to confirm

Here the use for those branche, the finish should not be very important but I try to learn to improve each time ! It will be a Mitten dryer

Thanks @bobstro 🍻 👍

Don't know if all this was X Nozzle related in the end time will tell.

RE: Prusa i3 MK3S - New Nozzle X and print quality

Ah, I should have mentioned: I used 3D Solutech green PLA. Just some spare filament I have to test with.

Interesting to see what the final product is!

RE: Prusa i3 MK3S - New Nozzle X and print quality

@bobstro

I wish I would have read this before buying the Nozzle X. I had purchased a hardned steel nozzle before and had exactly the same issues I am having with the Nozzle X.

I guess I will just have to go back to brass 🙁

Does this mean that our next stop is only the Ruby one which is made of Brass but has the additional stength?

Thanks for sharing your thoughts

RE: Prusa i3 MK3S - New Nozzle X and print quality

[...] I wish I would have read this before buying the Nozzle X. I had purchased a hardned steel nozzle before and had exactly the same issues I am having with the Nozzle X.

If nothing else, Nozzle-X nozzles are coated, so it might be a bit more pleasant to use with PETG. They are good nozzles, but they're very good HARDENED STEEL nozzles which isn't apparent in some of the advertising and hype.

I guess I will just have to go back to brass 🙁

Check out P3-D nozzles. If you're not printing actual abrasives, I've found their Apollo series very nice. They're made from an aluminum alloy that is harder than brass while offering better thermal characteristics than brass. Not as hard as hardened steel, but mine have held up well with non-abrasive filament printing. They are also finished with a non-stick, high-hardness coating.

Does this mean that our next stop is only the Ruby one which is made of Brass but has the additional stength?

The ruby is very expensive and very fragile. Search around here and you'll find some threads on tungsten alloy nozzles. They're also pricey, though not as bad as the rubys (~$70US IIRC) but are many times harder than steel with outstanding thermal characteristics, not to mention indestructible. The P3-D I mentioned are also good. E3D's nickel-plated copper nozzles are also very good.

RE: Prusa i3 MK3S - New Nozzle X and print quality

@bobstro

Thanks for your comments....I just left this review on the E3D website to make sure more people is aware about the complexities of using these Nozzles, hope it helps more people. I love the 3D printing world which I knew nothing about 6 months back, but I honestly feel that the printer should work for me, and not me for it. So spending an incredible amount of time trying to fix "problems" or aligning stuff to get good prints, is not something I am fond of 😔

Nozzle X and Reinforced Stainless Steel review (My experience):

Unfortunately I fell for buying the Reinforced Stainless steel 0.4mm Nozzle when I purchased my Prusa MK3S Kit. I decided to give it a try some months after printing quite a lot. It was quite painful to configure, I tried adjusting temperatures and all but I wasted so much time without achieving similar results as with the Brass nozzle that I went back to Brass.

Then I decided to give Nozzle X a try, I was attracted by the "One Nozzle Fits all" line, I thought, well, it sounds compelling that I could install a "Mega Nozzle" that would allow me to print with any material without having to worry about deterioration when using abrasive filaments. So I bought it and installed it. I had exactly the same underextrussion problems I had with the reinforced stainless steel one. In essence, they are very similar apparently. I mistakenly assumed the Nozzle X would have had similar thermal properties as the Brass one, unfortunately I was wrong.

So here we are, I am back to brass, and have 2 nozzles I cannot use because I was unable to find the correct configuration to get a similar performance as with the brass nozzle on the Prusa MK3S. I just wish there would be more clarity before purchasing both Nozzles which I now cannot use for anything else so I could have taken a better informed decision.

RE: Prusa i3 MK3S - New Nozzle X and print quality

I had those PID calibration to do but since then it's the nozzle X for Everything! And it work just great! From Prusament PLA and Pet-g, Tough PLA, Protopasta HTPLA-Cf, glow in the dark or anything I have throw at it just work perfectly!

But I fallow @Bobstro advice! I did once the PID calibration. Then all filaments got extrusion calibrated even Prusament and it's fantastic! Thanks again @Bobstro

Check out is startup gcode to perfect first layer/pinda temp optimization.

All his note are very useful!

http://projects.ttlexceeded.com/3dprinting_live_z_calibration.html

RE: Prusa i3 MK3S - New Nozzle X and print quality

@bobstro

So here we are, I am back to brass, and have 2 nozzles I cannot use because I was unable to find the correct configuration to get a similar performance as with the brass nozzle on the Prusa MK3S. I just wish there would be more clarity before purchasing both Nozzles which I now cannot use for anything else so I could have taken a better informed decision.

Times have changed. Unlike two years ago, when even decent brass nozzles were expensive, now you can buy 30 for $8 on amazon that are of "good enough" quality (obviously steer toward only the ones with the best ratings). So, rather than pine for an indestructible nozzle, a case can be made for benefitting from thermal properties of el cheapo nozzles and now simply change them out for new ones if they ever become suspect. At least at large diameters--I'm less sure about smaller diameters, where slippery plated surfaces might (?) still be worth it.

I've purchased a couple spendy smaller diameter plated "copper alloy" nozzles, always hoping for better-than-brass thermal performance. The name kinda suggests it, doesn't it? However, with no real spec sheet I do wonder whether "copper alloy" is just a fancy name for brass. 😣

RE: Prusa i3 MK3S - New Nozzle X and print quality

@dimprov

I get your point and your probably right ! I very happy with the nozzle X and dont see why I would not use it ... I also change the Heartbreak for an E3D titanium original to get rid of some Heat creep But to that was for very small perimeter low layer always retracting parts... but did not see any of those defect since!

I would really like to be able to do quick nozzle change that would not throw out the first layer and have to put time into it... so I stick to Nozzle x 0.4 for a wile ;o) Markforge make cupper with a steel insert I wonder how good it could be on MK3 .

Those ruby I would steer far from them since they dont have proper flow design in my opinion...

RE: Prusa i3 MK3S - New Nozzle X and print quality

Times have changed. Unlike two years ago, when even decent brass nozzles were expensive, now you can buy 30 for $8 on amazon that are of "good enough" quality (obviously steer toward only the ones with the best ratings).

Hmm... I'm in the "it depends" camp on this one. I tried some of the Amazon bargain nozzles. They do work, but I eventually realized I was getting a lot of stringing and quality issues and switched back to the higher class of clone nozzles. I noticed two things:

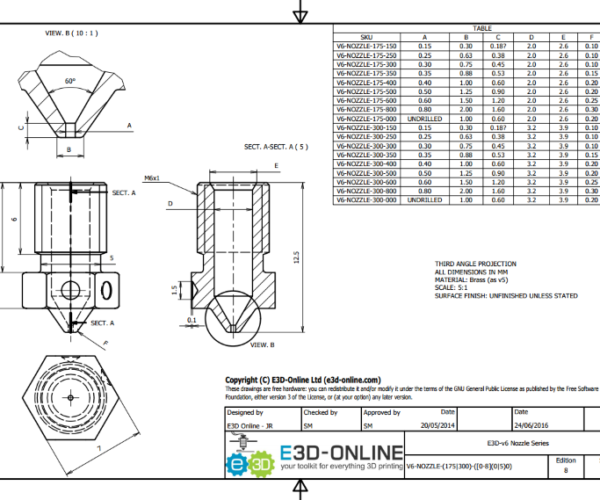

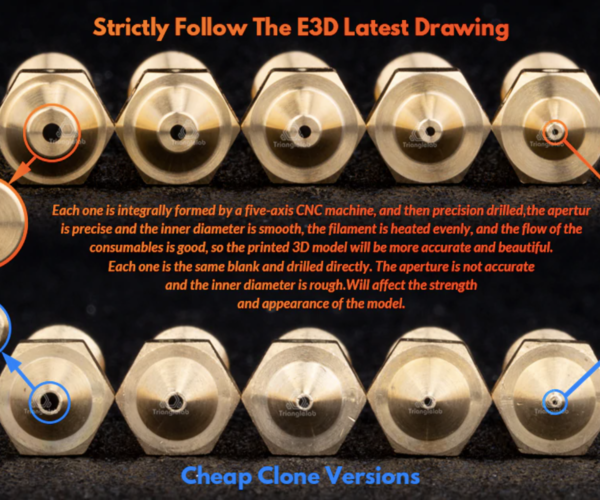

Some of the cheaper nozzles are very soft, and will wear or deform quickly. If your nozzle drags, or you ever try to clear a clog with a needle (I don't anymore), the edge of the opening can deform and cause stringing problems.

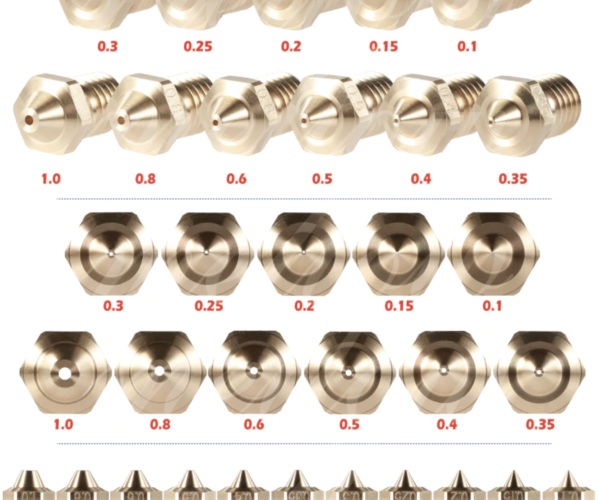

The very cheap manufacturers save money by printing all nozzle sizes from the same size blank. This means that the thickness of the nozzle around the opening will not conform to E3D's standards. With the higher-quality nozzles, the B dimension shown in the E3D drawing for V6 nozzles below varies depending on the nozzle size. This is what allows you to get good print quality using extrusion widths up to roughly 200% of the nozzle opening (though 120% is recommended).

E3D (of course), P3-d and TriangleLab all adhere to this geometry. Some of the cheaper clones decidedly do not. TriangleLab are priced above the cheap clones but about half of E3D's prices if you're concerned about pricing. I haven't tried their hardened nozzles. Their coated seem nice enough. Here's TriangleLab's comparison.

Mellow seems to be producing nozzles that adhere to the E3D B dimensions but have a more pointy tip. I am having good luck with their 0.25mm nozzles on my Mk3 for printing miniatures. They've got a good image showing the varying B dimension of each nozzle relative to extrusion size.

The coatings and plating do, IME, help with keeping the nozzle clear and reducing the problem of filament clinging during printing. This, along with a silicone sock, helps quite a bit with annoying quality issues. How much of a benefit this is will depend largely on what materials and temperatures you print at.

[...] I've purchased a couple spendy smaller diameter plated "copper alloy" nozzles, always hoping for better-than-brass thermal performance. The name kinda suggests it, doesn't it? However, with no real spec sheet I do wonder whether "copper alloy" is just a fancy name for brass. 😣

One surprise when doing my maximum volumetric throughput testing was that the nozzle material didn't seem to make much of a difference in ultimate flow results. At higher speeds with large nozzles, better thermal characteristics are probably more important to avoid nozzle cooling, but it's not something I've observed.

RE: Prusa i3 MK3S - New Nozzle X and print quality

Hi all,

I too bought a Nozzlex a few weeks ago and had similar oozing issues.

After some experimentation - I discovered that by reducing the flow on the preset seems to be the answer - particularly for 'oozier' filaments like PETG, TPU and Nylon. I found that taking the Flow down to 0.95 or even 0.9 seems to do the trick.

I suspect this issue is caused by the special coating on the interior of the NozzleX that makes filament flow much easier than a standard Brass nozzle.

I am gradually creating a new set of filament presets that are optimised for NozzleX and just stick 'SN' (for Steel Nozzle) on the end of each new preset name. Its a bit of a pain, but it's worth it for a nozzle that should last a long time and enables me to print Carbon Fibre infused filaments without worrying about wear on the nozzle.

Good luck.

RE: Prusa i3 MK3S - New Nozzle X and print quality

BTW by 'Flow' - I mean the Extrusion Multiplier in the Filament preset, to avoid confusion!

RE: Prusa i3 MK3S - New Nozzle X and print quality

Mellow nozzles are quality nozzles. I have been using them for about 6 months. I have zero concerns about quality. I did not have to adjust any settings to get quality prints.

--------------------

Chuck H

3D Printer Review Blog