RE: PRUSA edition heat break easily jam/clog with PLA

I ordered trianglelabs bimetal heatbreaks. I am very happy with the quality and thermal properties. I have had fewer jams with this product. I just ordered 3 more to add to a few more printers. Every product from trianglelabs has impressed me.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

@sinoth

Seems like my Prusa MK3S is having the exact issue as described. Just ordered a real E3D heatbrake to test.

I have had trouble printing any PLA under 0.15mm layers with any kind of retractions etc.

RE: PRUSA edition heat break easily jam/clog with PLA

@charles-h13 - FYI - I ordered a TriangleLab bimetal heatbreak for my Sidewinder recently. It worked very well for about a week before I started having problems feeding filament in when swapping spools. Reading some of the reviews and other comments, it sounds like the assembly can shift or loosen over time. I've reverted to a solid, one-piece Titanium heatbreak.

TriangleLab is normally excellent, so this may have been a one-off defect. If you notice rough feeds, it's something to keep in mind.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

@bobstro

Interesting. I have one with no problem. Maybe it is a one off problem or I just got lucky.

--------------------

Chuck H

3D Printer Review Blog

RE: PRUSA edition heat break easily jam/clog with PLA

[...] Interesting. I have one with no problem. Maybe it is a one off problem or I just got lucky.

TriangleLab makes good stuff, so hopefully just an anomaly. However, given how much the "Prusafied" E3D heartbreak seems to be with the 2.2-2.0mm step, the possibility of introducing any sort of imperfection in the feed path is a concern. I'll probably try a bimetal heartbreak in the future, but I think I'll pop for a genuine Slice Engineering version for the same reason I went genuine E3D on my Titanium upgrade.

With the smoothness of operation I'm getting now (completing multiple non-stop 24-36 hour prints of a sheet full of miniatures printing with a 0.25mm nozzle and LOTS of retractions, adding a bimetal heartbreak is a solution in search of a problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

I am about to upgrade my heatbrake from Prusa to E3d on my December 2019 Prusa.

Attached photos show the problem I am having on the standard Prusa-ifed heatbrake:

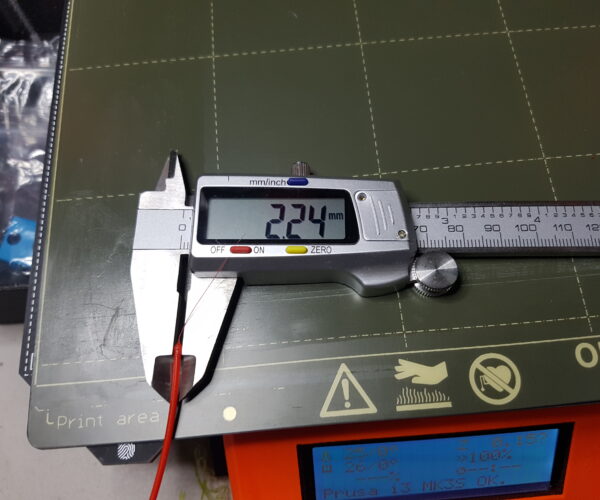

The 8 hour print failed about half way through because the PLA was melted into a 2.2mm blob in the cold part of the heatbrake and 2.2mm cold PLA won't fit into a 2.0mm metal tube.

Calipers showing the failure is because the melted PLA was 2.2mm wide.

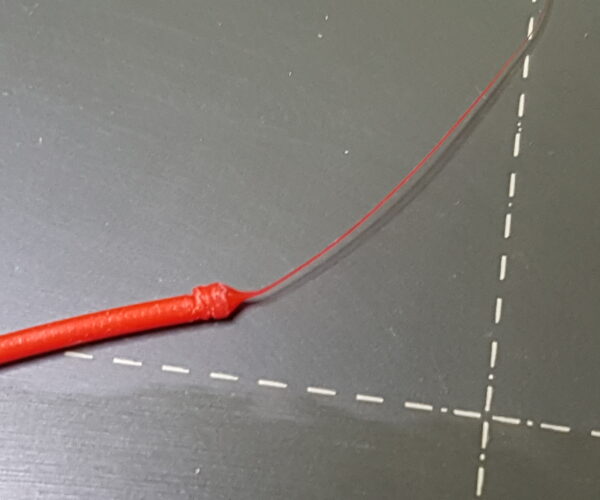

Calipers showing the failure is because the melted PLA was 2.2mm wide.  The point at which the PLA was melted and stuck in the heatbrake

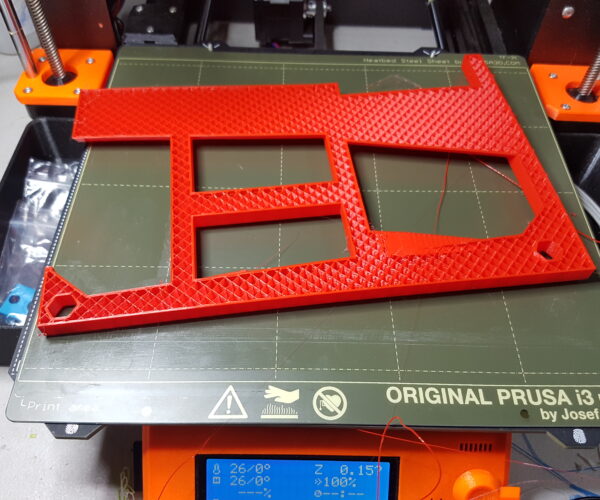

The point at which the PLA was melted and stuck in the heatbrake  An eight hour print that failed on a retraction after many hours.

An eight hour print that failed on a retraction after many hours.

RE: PRUSA edition heat break easily jam/clog with PLA

It looks like replacing with the E3D heat brake has solved my problem.

After installing the E3D heat brake, I have started printing using the same filament and gcode that would clog previously. It has run for 30 minutes on a 0.07mm layer minature figure and not a single click from the Extruder.

RE: PRUSA edition heat break easily jam/clog with PLA

Yep, even on a model with hundreds of retractions at 0.05mm I have not issues now. Not in 12 months of owning this printer have I been able to do that.

RE: PRUSA edition heat break easily jam/clog with PLA

I wonder why prusa decided to change heatbreak for their printers...? (I changed it to E3D, too).

RE: PRUSA edition heat break easily jam/clog with PLA

@protoncek

Some years ago, Prusa introduced the first multi material unit and they started getting feed failures...

the modified heatbreak was introduced to resolve the problem,

the revised design was considered successful and introduced across the range and later adopted by the mk3 and mk3S and the MMU2S

And now it gets blamed for every extrusion issue Lol...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

Joan, thanks for explanation.

I didn't have problems with original heatbreak, though (once i added fan to extruder motor), i changed it because original one was a bit bent (why-when i have no clue...) and i decided to go with E3D instead, i just wonder why is that... E3D itself still doesn't sell such modified heatbreaks in their models, they sell them specifically for Prusa printers. I dont' blame anyone, i just wonder...

It's not exactly logical for filament to be wider at the end and expect to go out through smaller hole backwards...

If this modification must be there for the reason of possible later MMU installation then ok...

RE: PRUSA edition heat break easily jam/clog with PLA

@Joantabb,

I understand prusa made a revised version and why it might help a bit with MMU filament retraction. But I don't understand why you alway's make fun of the idea that this exact same revision is also to cause for jams in certain combinations of events.

I have done several tests on my side and did several posts about it that seems to proof the modded heatbreak might be the cause of these jams. And I'm not alone in this, other people have tested this too, and a lot of people who changed the heatbreak report to no longer have this issue.

Why do you keep waving this issue away? Please help me understand, these people give valueble feedback to improve YOUR (and our) prints. It is in everybody's interest to at least take it a bit more serious.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

I will sum up one more time what might be the problem in the hope it makes sense enough to maybe do some testing about it.

To my idea the jamming occures in the following combination :

A + B + C

Where ABC is the following

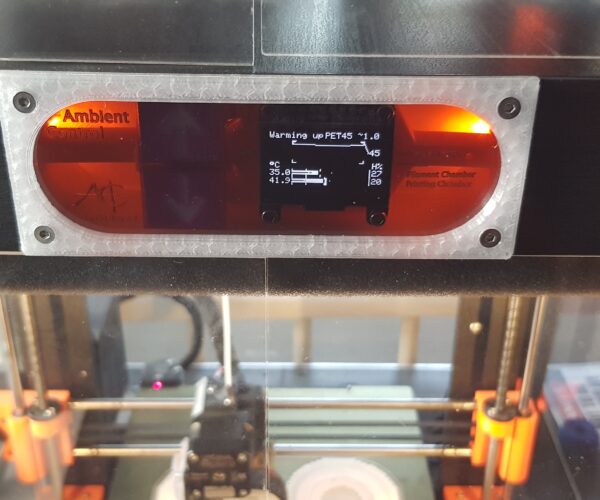

A = Warm Ambient Temperature (~30°C+)

B = Hot Extruder Stepper Motor (~50 - 70°C+)

C = Prusa Modified heatbreak with the narrowing down from 2.2 to 2mm.

And to give some personal details about A, B and C :

A : Warm Ambient Temperature (~30°C+)

Just an example, but I can set my ambient temperature... here it is 41.9°C. So I can reproduce 30+ tempreratures.

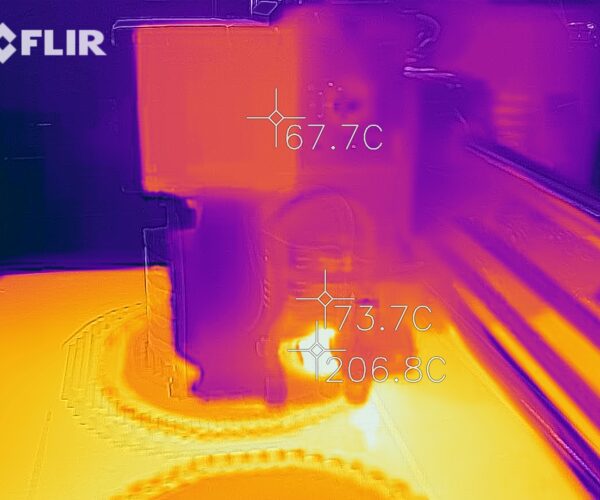

B : Hot Extruder Stepper Motor (~50 - 70°C+)

Here you can see my extruder motor actually goes over the glass transition temperature of PLA, here it is sitting at 67°C. This is an extreem example, but it is clear to me that the motor can go over 60°C sometimes. Thus the metal shaft and gears are also heating up quite high and in turn should/would be pre-heating/softening up the PLA already when entering the heatbreak.

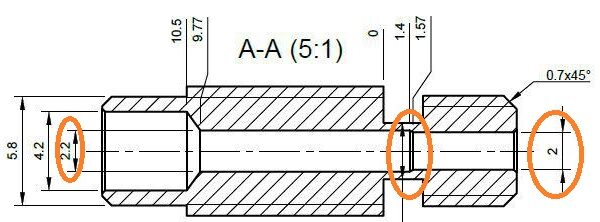

C : Prusa Modified heatbreak with the narrowing down from 2.2 to 2mm.

Well that is just in the design :

I can recreate this problem, so I don't understand why it is waved away.

True, I'm not saying i'm 100% certain this IS the problem... but to my senses it sounds very possible that this might be the problem and worth checking out.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: PRUSA edition heat break easily jam/clog with PLA

Well, i dont' quite understand how 2.2mm wide filament CAN go through 2mm hole anyway... except if you pull it out while it's still hot and chewy...

But, in any case if this really helps solve MMU problems then we, who have printer without MMU unit are victims of this "solution"... some kind of punishment because we didn't bought MMU unit... 😪

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

Hi Wouter,

I am not making fun, just noting that what was brought in to counter one issue, is now assumed to cause a different problem.

Some folk get on with the modified heatbreak, some don't...

My approach, adjusting temperatures and retractions is often disregarded...

no pproblem, it works for me...

I have two printers using the modified heatbreak, a Mk2 with MMUv1 and a Mk3s with MMU2S

I also have a Frankenprusa with a titanium heatbreak and a mk3 with a Dragon heatbreak.

Frankenprusa is a mishmash of Mk2 Frame with Mk3 Electronics, so is effectively a mk3ish printer... the titanium heat break was an experiment, seems to work,

Both of the printers with Modified heatbreaks seem to manage high numbers of filament insertions without jams.

perhaps there are different production runs, with different tolerances, I don't know. have you been able to check the accuracy of the machining? I don't have the technology.

I fully support your efforts to improve the performance of the technology while you are doing so, could you look into the ptfe liner in the heatbreak, this interface also seems to cause issues for some folk,

I considered pinning the heatsink to the heatbreak, and the heatbreak to the heat block, to aid nozzle changes. but eventually changed to a dragon hot end. which both allows easier nozzle changes and moved the PTFE / heatbreak junction further away from the hot end.

we have different approaches both aiming for improvements that help us enjoy printing...

I would be interested to know whether Prusa use the modified heatbreak in their print farm...

I believe in the early days they used 2.85/3mm filament for the print farm, so the heatbreak would have been different then.

I think they now use 1.75mm filament.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PRUSA edition heat break easily jam/clog with PLA

[...] Why do you keep waving this issue away? Please help me understand, these people give valueble feedback to improve YOUR (and our) prints. It is in everybody's interest to at least take it a bit more serious.

I certainly haven't read any of Joan's comments as waving anything away. I do think that there is a tendency to identify something that worked once and declare it the cure-all for all ails. When I started with my Prusa Mk3, I (and Joan far more frequently) helped several people diagnose jamming problems that we traced to friction in the feed path, and particularly issues with the extruder idler becoming unseated. Other people were using overly-aggressive retraction settings. At various times, adjusting extruder motor current has been identified (twice) as a problem. One guy on the Prusa Discord refused to let anybody discuss heat creep issues without insisting it was a current issue. "Heat creep" has been declared "solved" at least three times (ambient temps, extruder motor heat and lower hotend clogs). The 2.2-2.0mm step is aggressively hailed by some as the one and only true fix.

I'm all for doing what works in a pinch, but I was able to print for over a year without issue using the 2.2-2.0mm heatbreak. My extruder motor has never run excessively hot even when running detailed prints with thousands of retractions. I have encountered problems that could have led to these issues, but what I have done is spent time looking at all of the possible causes of excessive friction and heat and worked to reduce all of them.

I won't speak for Joan, but I'm going to caution anybody declaring that they've found the "one true fix" for these problems that the Mk3 is a complicated device and lots of things need to work well (and nearly perfectly) together to produce quality prints. That's not waving anything away, but along on some hard-won wisdom. More notes on the topic here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

@wouter-h3

Hi,

yes, the reason C is the key, but A and B are only some culprits.

As I explained in details at page 1 in the first post, in THIS DOCUMENT the real disaster receipt is the following:

- the environment temperature: the more higher the easier will be for PLA to reach the glass transition.

- the PRUSA Heath Break with double internal diameter 2.0 and 2.2 mm: (this blocks the PLA and cause the jam. No discussions.

Removing this element and replacing it with E3DV6 Original heath break solve the issue.) - A bad settings in PrusaSlicer that does not keep in consideration the real flow capability for that specific filament according the speed.

- A lot of retractions.

- Insufficient cooling of the lower part of the heatsink / too much heat in the upper part of the heat break (it allows PLA to take the shape of the tube)

When you have all this, and you print a big piece with high speed:

- The wrong speed setting in PrusaSlicer force the MK3 to print too fast

- At that speed the PLA is not able to exit from the nozzle at the required quantity

- The pressure in the nozzle and heat break increases

- Since they are well over the PLA glass point, the PLA start to get the shape of the tube, thanks also to the high pressure that is applied by the extruder motor due to the wrong high speed.

- The infill provoke many consecutive retractions, and the filament become like a pneumatic hammer, that pushes and models the PLA against the metal, and the PLA slowly take the exact shapes and diameter of the upper part of the heat break : a 2.2 mm cone.

- Those movement also cool a little the PLA so that it becomes solid enough, that with its diameter cone of 2.2mm, it can not pass any more in the 2.0 mm lower section, and so it can not reach the hot part any more.

- THE PRINTER IS NOW JAMMED.

That is, very simply.

RE: PRUSA edition heat break easily jam/clog with PLA

[...]

- The infill provoke many consecutive retractions, and the filament become like a pneumatic hammer, that pushes and models the PLA against the metal, and the PLA slowly take the exact shapes and diameter of the upper part of the heat break : a 2.2 mm cone.

I suspect this is one of those issues that explain why some people persistently see the problem and others don't. I don't understand why anybody would want to slow down their prints by using retractions on infill that is going to be entombed in plastic for the foreseeable future. I have always enabled Print Settings->Infill->Advanced->Only retract when crossing perimeters which may explain why I never had the issue when I was running an original Prusa heatbreak.

That said, I went ahead and upgraded to an E3D titanium heatbreak and nickel-coated copper block when doing a teardown simply because it was a convenient time to do so. Swapping hotends will certainly do no harm, but it's not going to help if your underlying problem is a constricted filament feed path or jammed extruder idler. It may not be a universal fix if you are printing at excessively high ambient temps or have other factors that contribute to heat in the extruder and your jams are occurring there.

So yes, that sequence of events may indeed result in jams, but it is by far not the ONLY cause of jams. Systematic diagnosis and troubleshooting is still going to be required. No one magical incantation or part replacement can fix all ills.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PRUSA edition heat break easily jam/clog with PLA

Replacing the heatbrake is relatively cheap and easy. In my mind if anyone is getting jams and they measure 2.2mm on the plug they pull out, buying an E3D heat brake would be my first suggestion.

I am in Australia and suspect that my issues related to the fact I was using one brand of locally produced PLA that is fantastic, just probably has a glass temp a bit lower than other brands, and only Australian's would have any reason to buy this local PLA.

So I am very glad for the research done by others, especially @antimix that lead me to try this fix and solved my issue.