Oozing

When printing molten filament starts to ooze up the heatbrak and in-between the heatblock and sink. I have tried EVERYTHING!!!!!!

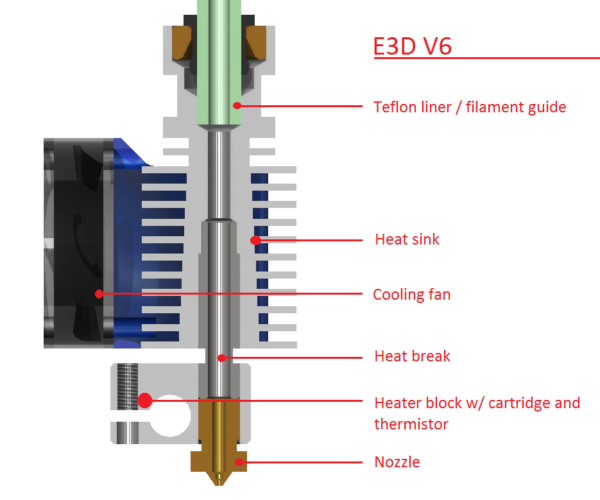

When i reassemble it I put the nozzle in all the way and loosen it 1/2 - 3/4 of a turn screw in the heatbreak all the way and then tighten the nozzle to the heatbreak not the heatblock. IT JUST WONT STOP!!!!!

Please help I need it... a lot

RE: Oozing

This is almost always due to a poor seal between the bottom of the heat break and the top of the nozzle.

Many people don't realize how much pressure is in there, and when under pressure, if there's any discontinuity, the pressurized molten filament will find it.

If there is debris on the bottom of the heat break or the top of the nozzle, it can prevent a good seal between the two. It may require disassembly of the hot end to diagnose and clean it, if it persists after you are sure that you have a good solid contact between the heat break and the nozzle.

RE: Oozing

Also make sure you do not over tighten the nozzle. It is supposed to be tightened with 2,5 NM only. If you exceed this torque you might damage the heat block and cause the leakage.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Oozing

It's obviously a misassembled hotend. Did you hot tighten the nozzle at 285 degrees?

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Oozing

And once you've got it working again, print one of the 3 Nm torque wrenches at https://www.prusaprinters.org/prints/24539. They work great.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Oozing

yes

RE: Oozing

I have a torque wrench so Ill use that when assembling it so i can make the 3d printed one