Leakage after nozzle change - help requested, questions at the bottom.

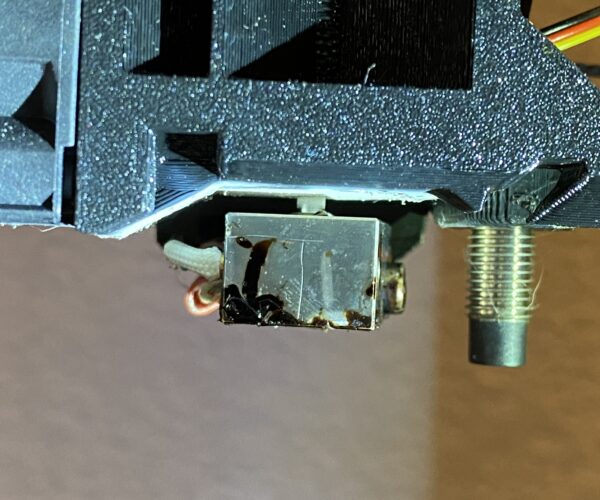

After several months and hundreds of hours of good prints, I changed the nozzle for the first time on my MK3S+, installing a .8mm nozzle. I had two successful prints. The third print generated a thermal runaway, after which I thought I saw some filament leaking. I removed the nozzle. The picture is below. Clearly it leaked. All the leakage that I've seen is on the nozzle threads, although I haven't taken anything else apart. From the outside, that's all the leakage I see.

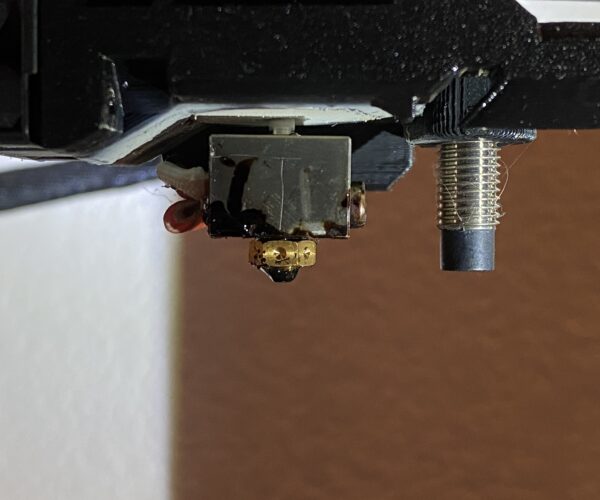

Here are two pictures of what the block looked like with the nozzle removed. Note that the burned filament on the front of the block is from a previous blob issue with the old nozzle and wasn't cause by this problem.

I reinstalled the nozzle that leaked. Here's what it looked like reinstalled:

I have a few questions:

- Any thoughts on what I did wrong and how I can fix it? I thought the various spacings looked right (e.g. between the nozzle and the heater block). Did I not tighten it enough?

- Can I salvage this nozzle or do I need to clean the threads (or get a new nozzle) before printing again?

Thanks.

RE:

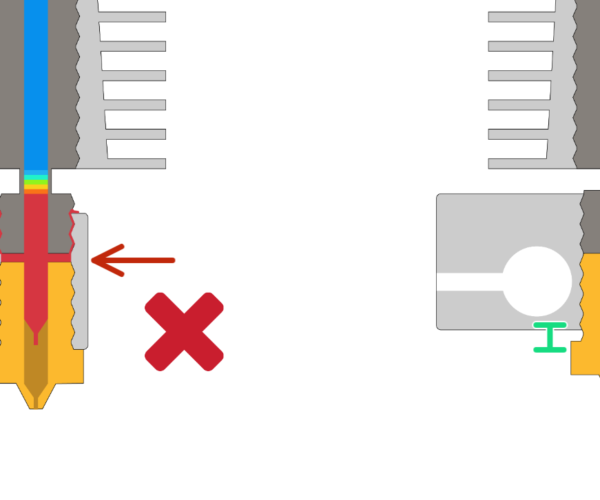

Two common mistakes:

Not hot tightening the nozzle. Needs to be tightened at 285 degrees, at 2.5 to 3 Nm. I use a 3D printed torque wrench.

Not correctly assembling the hotend. If you didn't hold the heater block properly and you somehow managed to partially unscrew the heat break and then left a gap, it'll leak. The gap between nozzle and heater block is not one created by the user. Instead iif the heat break is screwed in properly, then tightening the nozzle will create that gap if you want it or not.

More likely than not the nozzle is going to be okay. I'd heat it up with a heat gun to melt the filament and clean it with a brass brush. I do that with all the nozzles that come out of the printer at nozzle swaps.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Leakage after nozzle change - help requested, questions at the bottom.

Thanks for the reply. That helps. I did hot-tighten the nozzle, but without a torque wrench. I may not have tightened it enough.

How would I know if the heat break is partially unscrewed? If tightening the nozzle leaves a gap, can I be confident that it is ok? Is there some other way to check?

Thanks.

RE: Leakage after nozzle change - help requested, questions at the bottom.

If you tighten the nozzle and there is a gap, then the heat break should be screwed in properly. Everything else would require disassembling the hotend.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Leakage after nozzle change - help requested, questions at the bottom.

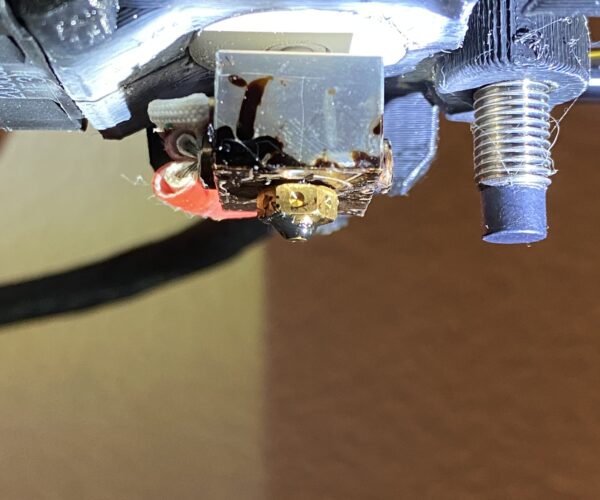

I cleaned the nozzle and reinserted it, tightening it up by hand. For removing and re-installing, I had the temp at 285C. But now it is leaking worse than before. Here's a picture. Any thoughts?

RE: Leakage after nozzle change - help requested, questions at the bottom.

That nozzle doesnt look like it has the required gap though. every single picture is showing no gap. That combined with the fact that there is leakage working down the threads means it is NOT sealed against the heatbreak properly. If there's plastic working down the threads and out it will also be working up the threads of the heatbreak and onto the top of the heater block too.

At this point I would disassemble anyway to make sure all the threads are cleaned out on both the nozzle, block and heatbreak. I would also then make sure the mating surfaces of the heatbreak and nozzle are clean and polished with no damage. If the surfaces arent flat and clean then they wont seal when screwed together.

Then when reassembling screw the heatbreak into the heater block a couple more turns than it is now. Basically you can screw in the nozzle till it has a nice suitable gap that is clearly visible (at least 0.5-1mm), then you screw in the heatbreak to meet it. Restore the heatsink on top and fit it all back.

Then do the hot tighten process.

As you will have adjusted the heatbreak position you WILL have to redo the initial calibration to get the basic z height set and then finally a proper fine tune of Z as usual.

RE: Leakage after nozzle change - help requested, questions at the bottom.

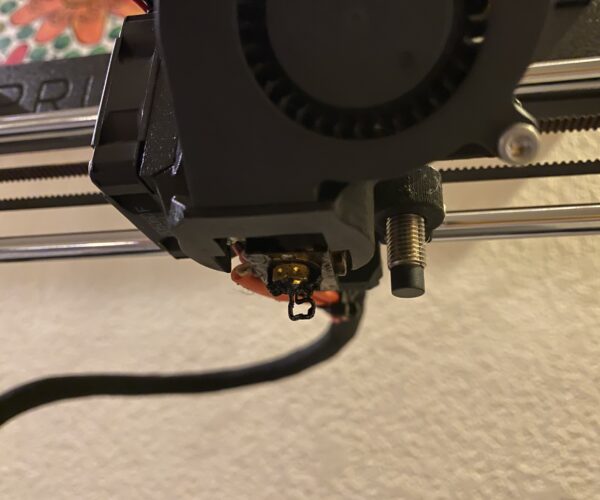

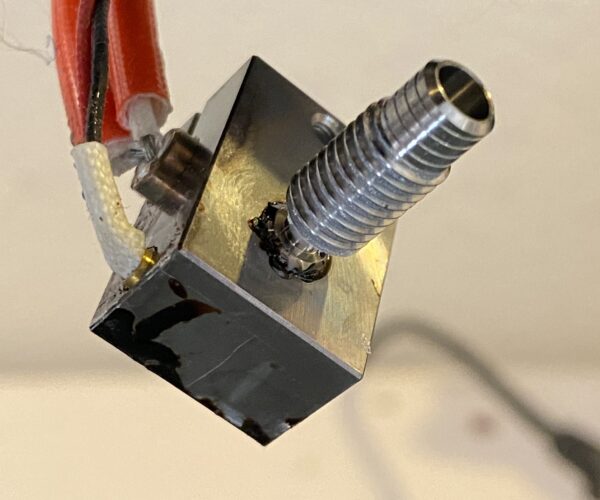

Thanks for all the replies. This is helpful. I noticed that the gap was gone as well. I think I must have dislodged the heat break when I first changed the nozzle. I'm disassembling the hot end and got the the point below. The heat break is lodged into the heat block because of filament. I'm not sure how much pressure I can put on it.

Can I safely turn on the printer and heat up the heat block so I can remove the heat break? Or is it better to use a hot air gun? Or should I just replace this part altogether?

RE: Leakage after nozzle change - help requested, questions at the bottom.

Turning it on should be okay. I've done that before many time. But a heat gun should also work.

I have a complete hotend in the drawer, just in case 🙂

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Leakage after nozzle change - help requested, questions at the bottom.

Thanks. After talking with technical support, I heated it up and was able to unscrew the heat break. I'm going to clean them up a bit and I have some new thermal paste on the way for when I reattach the heat sink. I've also ordered a complete hotend in case I don't get this one working again 🙂.

RE: Leakage after nozzle change - help requested, questions at the bottom.

Just to close out this thread - after spending time cleaning the heat block and heat break, I realized that damaged the threads in the heat block. I decided to have a clean start so I just replaced the hot end. I’m keeping the old heat break and heat sink around as spare parts. Got it installed tonight and the whole thing works again. I’m glad I built this from a kit rather than buying it fully built - it made the whole process much easier.

Thanks again for all the comments.

RE: Leakage after nozzle change - help requested, questions at the bottom.

On your old heater block you can heat it up and use an M6 screw to chase out the threads and clean them up to make it ready for its backup job. The heatbreak is a delicate item so its best not to use it to clean out the threads.