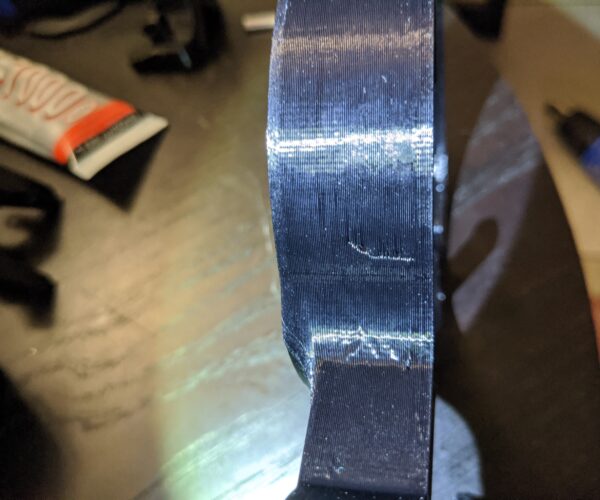

gaps in seams after upgrading to a .6mm nozzle

I'm printing with a mk3s+ prusa with a e3d x .6mm nozzle using pruse slicer

PETG at 255 C

I calibrated the K factor but it didn't seem to fix the gaps completely

I tried increasing the detraction speed to 45 but that didn't seem to have too much effect.

I changed the value on "extra length on restart" and that seemed to have fixed the gaps but it feels like I’m bandaiding the issue and not resolving the root cause.

Some of the inside seams are fine

RE: gaps in seams after upgrading to a .6mm nozzle

Are you using the 0.6mm nozzle preset in PrusaSlicer? 0.4mm G-Code on a 0.6mm nozzle would likely have printing problems.

RE: gaps in seams after upgrading to a .6mm nozzle

Are you using the 0.6mm nozzle preset in PrusaSlicer? 0.4mm G-Code on a 0.6mm nozzle would likely have printing problems.

Yes I am using the .6mm nozzle preset and have done every tweak imaginable. So far the only solution I have found is placing the seams on the inside of the print.

RE: gaps in seams after upgrading to a .6mm nozzle

I disabled "retract on layer change" and "wipe while retracting" and it seemed to have solved my problems. Still ugly seams but they are solid.

Running Mk3.5 with Prusaslicer 2.8.0 and 6.0.4 firmware.