Filament leaking over eater block, but I can't screw the nozzle in more.

I'm running into an issue with my MK3. I have filament leaking over the top of the head block, but I can't screw my nozzle in more to close the gap.

I'm not sure what I should do to address the issue, nor how I got into it in the first place. I do switch out the nozzles from time to time, but as far as I know I shouldn't be able to loosen the heater block to the point where the nozzle wouldn't meet the hot end.

Any Ideas?

RE: Filament leaking over eater block, but I can't screw the nozzle in more.

Please please read and understand the nozzle changing instructions.

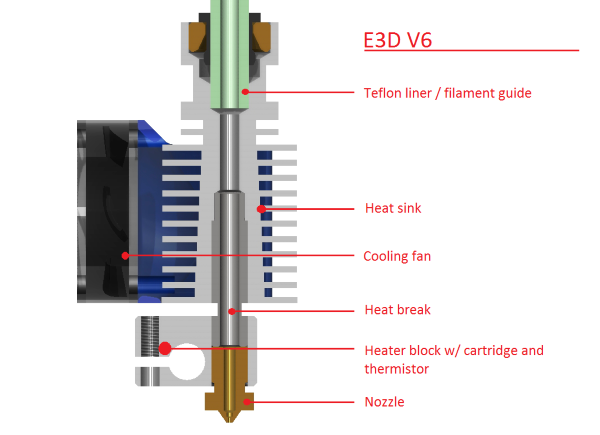

The seal is NOT between the nozzle and the heater block like you have pictured. That will not seal and you will get plastic leaking.

The seal is between the nozzle and the heat BREAK. The join is inside the threads. In effect the heater block is acting as a big nut to hold the ends of the nozle and the heat BREAK together. That is why there should always be a .5-1mm gap between the nozzle and heat block, due to the fact that its butting up against the heat break and so cant go in any more. If its doesnt do that then plastic leaks out between the 2 and moves both UP and down the threads so can leak out on the top and/or bottom of the heat block.

When you start with a completely disassembled unit it common to fit the nozzle and leave the suitable gap and then screw in the heatbreak till it meets loosely. The you can fit the heatsink etc. After its all assembled you then do a tighten at around 285 degrees. That insures all parts have expanded fully due to the heat and then it literally a final snug up to torque .

You are going to have to clean off all that plastic (being VERY VERY carefull of the delicate wires on the heater and thermistor), making sure its gone from the threads inside the heatblock and removed from the nozzle and heat break ends where they meet to ensure that those 2 surfaces are clean and flat otherwise you still wont get a seal when re-assembled.

RE: Filament leaking over eater block, but I can't screw the nozzle in more.

Thanks for the reply.

I read the nozzle changing instructions and understand them. In my reply I used the wrong terms when describing it, sorry it frustrated you so much. It sounds like what I'm running into fits what you're describing, so let me try to re-describe it:

My nozzle seems to not meet up with the heat break within the heater block. When I change the nozzle, I position the extruder so I can reach everything, raise the temp to 285, unload the filament, loosen the heater block, remove the nozzle, thread in the new nozzle, tighten the heater block.

Each time I do it I also pop up and review the video here to make sure I don't miss a step:

When I do all of this I'm finding that the nozzle does not meet up with the heat break within the heat block and I get a slight leak. The nozzle is able to screw all of the way in to the heater block (no slight gap).

Based on your reply, I'm assuming that what you're telling me is that I need to disassemble the extruder assembly, take the hot end apart, clean it, and reassemble it, correct?

If this is the case, do you have a suggestion of the best place to go to find instructions to do so? I'm going to look it up on E3D's site after I post this reply, but if you know of a good article and/or video I would appreciate it.

RE: Filament leaking over eater block, but I can't screw the nozzle in more.

@christopher-s55

Precisely that yes. You shouldn't need to remove the heatbreak from the heatsink but when its all cleaned off I would make sure that the heatbreak is screwed in far enough. I would have directed you to the e3d instructions anyway. Their procedure does NOT involve rotating the heater block at all. To me it sounds like the heater block needs to be turned another turn or even 2 on the heatbreak (when the nozzle is removed). This will result in the heat block sitting further up the threads and mean that your nozzle wont have to be screwed in so far to meet the heatbreak.

Of course this will have the side effect of moving the entire nozzle/heat block up slightly so you might need to reposition the PINDA probe up slightly too and you will have to redo the Live Z naturally.

Once its rebuilt all you really need to do to change nozzle is use the spanner to stop the heatblock from turning while you are removing/replacing the nozzle. There is absolutely no need to turn the heatblock itself. I don't know why prusa do it that way. You are twisting the wires to the heater and thermistor when you move the block and that's never a good idea if you can avoid it. Once you get the hand of it you dont even need to remove the part fan shroud, although doing so makes things easier to see.

Also get yourself a few E3d heatsocks for the V6 hotend. Keeps the vast majority of the burnt plastic off your hotend during normal use (but wouldnt help when its leaking out the top).

RE: Filament leaking over eater block, but I can't screw the nozzle in more.

Ok cool. That makes sense.

As far as cleaning off the heater block, what would you consider the best method of cleaning it. I know about heating it up while it's hooked in to the printer and using a brass brush, but is there a different way of cleaning it when the hot end is off of the printer?

RE: Filament leaking over eater block, but I can't screw the nozzle in more.

Pretty much the heat up and brass brush I'm afraid. If you have it separated from the extruder housing plastic then you can use something like a small vice or some vice grips/maul grips to hold it at the top of the heatsink area and stop it touching anything else. Not too tight though as the heatsink is aluminium and can be marked by steel jaws. Its best to leave it in the extruder top though when heating it as that way the cooling fan can still cool the upper area.

For smaller area something like a dental pick can be used to scrape away plastic. I use a set of those normally for cleaning up printed parts in difficult to reach areas anyway.