RE: Underextrusion on internal layers?

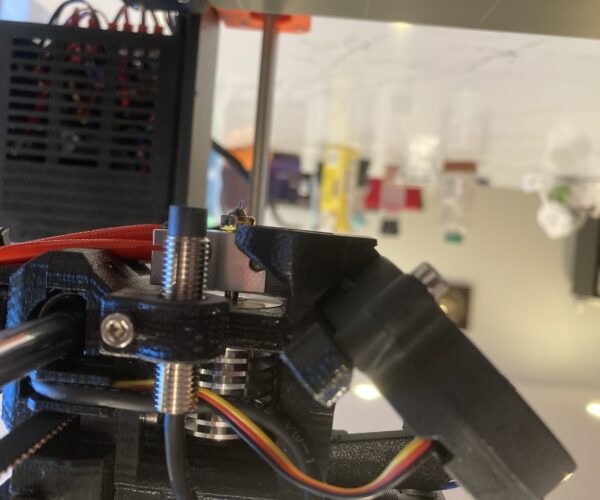

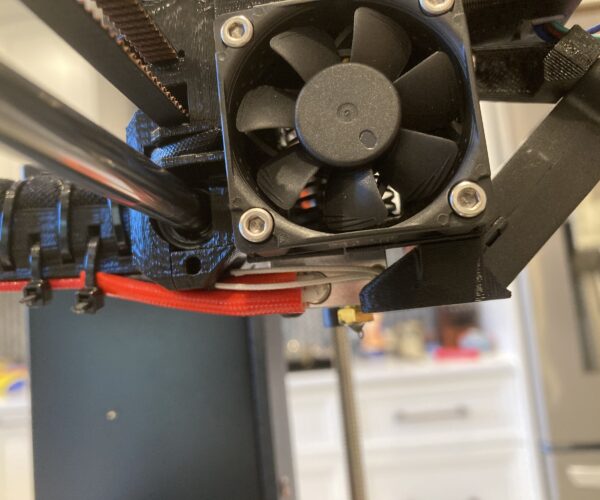

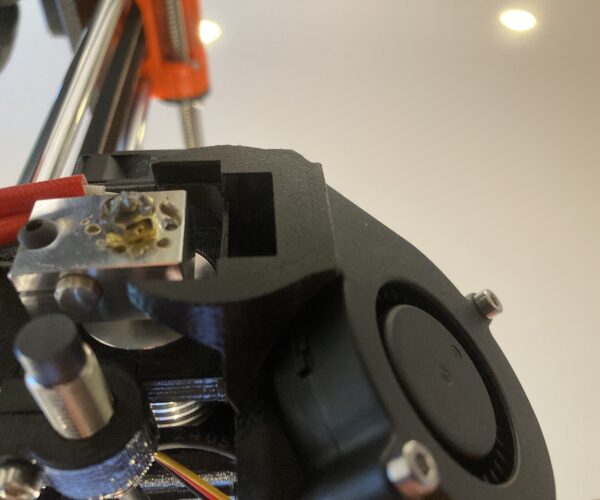

Thank you, Tim. Below are the photos of the fan shroud.

The temp in the display seems consistent during printing, doesn't change between first and later layers.

I've tried measuring the temperature of the nozzle with my temp probe, and it shows consistently 194C when the temp is set to 215C. I tend to say that my probe is wrong, but I'll check what it says for the bed and for different nozzle temps and will post back.

RE: Underextrusion on internal layers?

@doctorshtein

It looks normal - and it also looks like Prusa fixed the + mount so there's no chance of misalignment. A silicon sock might be worth trying, the non-pro version is better in that it won't catch curls as easily as the pro sock.

I take it Prusa hasn't helped you much?

RE: Underextrusion on internal layers?

@doctorshtein

One other "out there" request. After the next jam (or major under-extrusion), stop the print as quickly as you can, then immediately do a filament unload and take a sharp photo of the end of the filament you pulled out. I'm looking for a 2.2 mm diameter bulb at the stub. If the bulb is only 2.0 mm, that's normal. 2.2 mm is a problem.

RE: Underextrusion on internal layers?

@doctorshtein

As for the temp issue. Measuring a nozzle temp is tricky. Matt has a good thermocouple and seems to know how to use them. A normal probe (like the platinum sensors with some high end thermometers) won't do as well and will likely read low, just as you are seeing. An alternate way to tell if the nozzle is too low a temp for the material you're printing is to print what's known as a temperature tower. Or a simple way to find out is slice a part that is failing - but set the extruder temp 20c hotter. So a print that under-extrudes at 210c printed at 230c should improve under-extrusion - IF - it's caused by too little heat.

RE: Underextrusion on internal layers?

Thanks again for your help, Tim!

I've just finished talking to support (another ~4 hours), and it worked. What we did today, is disassembled the print fan shroud and put it back. My fan now has a slightly different tone on startup (same when it runs), and we also reconnected the thermistors tot he board (since I was measuring the resistance).

After that, we did another test print with a 1.1 extrusion multiplier, and it worked! It even extruded too much 🙂

Last time we did these tests we used 1.05 (since it's 0.95 for PLA by default) and it wasn't enough. I'm going to be doing more prints tomorrow with different multipliers to find the one that works best, but both me and support folks are puzzled how come the cube print did 0.43-0.44mm with 1.0 multiplier, when 1.05 isn't enough?

Perhaps poking around the fan shroud and the electronics connections made a difference?

Anyway, I'm super happy it prints now. 20 hours on the chat isn't for the faint of heart 🙂

RE: Underextrusion on internal layers?

@doctorshtein

I'm a bit surprised the print fan could cause your under-extrusion. If that were the case simply turning the fan off during printing would have cured the issue, as would cranking the nozzle temp up 10c. And I think you had tried higher print temps.

Also, increasing extrusion rates for inner layers will cause problems on outer layers. I hate to say it, but I doubt you've actually found the root cause. Maybe a bad connection on the thermistor, but even that seems a stretch.

Here's to hoping my gut is wrong.

RE: Underextrusion on internal layers?

I see what you are saying. I tried printing the calibration cube with 1.06 multiplier and it came out a bit thicker than 0.45 - mostly around 0.46mm, but it also got some weird texture on the sides (probably an artifact of the the overextrusion).

I am running all the tests that you've mentioned in both of the threads now. Will post back the results. Sorry I didn't do it earlier as promised - I spend all my free time with support in the previous days.

RE: Underextrusion on internal layers?

Here are the test prints I did today:

1. A regular print on default settings (215C, 1.0 mult, 100% speed) to confirm the issue still happens.

The issue manifested and I tried to pull out the filament ASAP. I measured 2.02mm at the end of the filament.

2. Print at 125% speed - issue happens, perhaps just a tiny bit worse than a regular print

3. Print at 205C (10 degrees lower than usual) - the issue happens, and is comparable to a regular print.

4. Print at 235C (20 degrees higher than usual) - the issue happened, but is significantly better than a regular print.

5. Print at 1.06 extrusion multiplier - layer looks really weird. On one hand, strands are melted together, but on the other hand, they are misaligned vertically within the same layer - every second strand is higher / lower then the neighboring strands. It looks like a tiny "wave". When I was printing at 1.1 mult yesterday, there were signs of overextrusion (extra filament between strands, that was easy to scratch off), but all strands were at the same height. Below is the pic from 1.06 mult

RE: Underextrusion on internal layers?

@doctorshtein

Using 1.06 multiplier isn't the answer - that layer pic shows typical over-extrusion.

Something is wrong, I'd continue to harp at Prusa to make it right.

That said - you probably want to use the printer. Perhaps modify a filament profile and set extrusion temp for PLA at 225c or even the 235c since that works with your hardware and the filament you have, save the profile as My PLA, and that will get you printing.

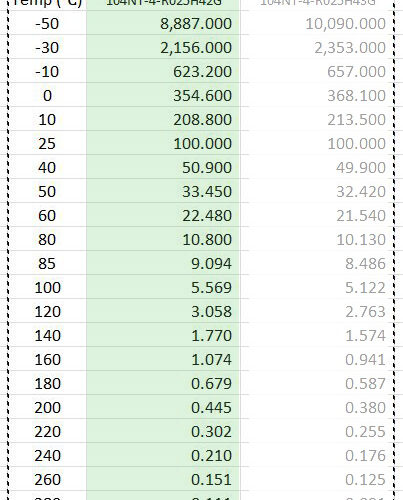

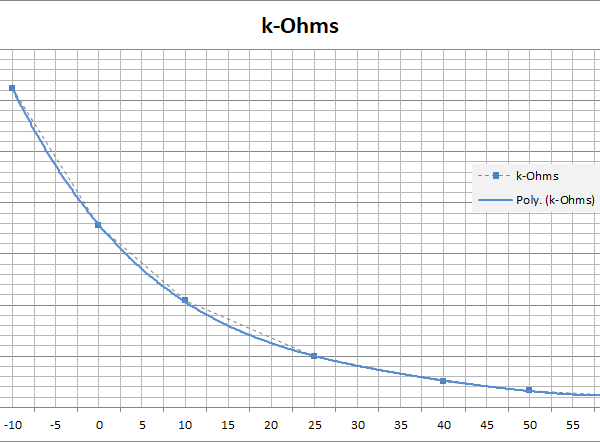

Generally speaking, printing hotter normally causes stringing; but in your case, probably not. And PLA is pretty forgiving for print temp, most PLA prints well between 190c and 230c, so parts you print at even 235c won't be deficient. Who knows, maybe your thermistor is just off. If you have a good DMM (4 1/2 digit or better) and an accurate temperature probe; you can verify the thermistor resistance using this table. I'd let everything cool down to room temperature, have the probe beside the heater block or even taped to it in contact with the heater block. Once you have a reading or three, be sure to remove the tape. lol.

Thermistors are generally quite high in precision, any measurable deviation from the chart and you might ask Prusa for a replacement. The resistance curve is nonlinear, I did a quick and dirty fit, interpolate at your own risk ... lol.

RE: Underextrusion on internal layers?

Thank you, Tim!

I'll continue to talk to the support.

Meanwhile, I tried measuring the resistance of the thermistor on the extruder. I would reheat the nozzle to a desired temp + 1 or 2 extra degrees C, and when it stabilizes, i would turn off the printer and unplug the thermistor from the board and measure the resistance ASAP. It would usually take me ~ 5-10 seconds to unplug and get the first measurement, so here's what I got:

| 22 C | 110.4 kOhm |

| 40 C | 51.7 kOhm |

| 50 C | 32.15 kOhm |

| 60 C | 22.5 kOhm |

| 80 C | 10.92 kOhm |

| 100 C | 5.56 kOhm |

| 160 C | 1.065 kOhm |

| 220 C | 0.310 kOhm |

Seems real close to the table you posted.

On the other hand, today I could finally repro that weird sound I get from the print fan during printer startup. It only sounds like that during printer startup, and not during printing. When i set it to 255 explicitly in the settings it also sounds fine. The sound file is attached.

RE: Underextrusion on internal layers?

@doctorshtein

The thermistor is probably okay ... they are rated +/- 3% at 25c. Print fan noise is also normal to my ear -- at least to what I have experienced with cheap sleeve bearing fans. My 3+ year old fan sounds about the same, and I honestly think its quieter today than when it was new. Spare fans, too.

Whatever is happening is well into fringe territory. Things like the idler door hinge screw is too tight, the PTFE tubing you got has a flaw and is too tight on the filament, the extruder motor has a bad magnetization or windings. I looked back at your original photo posts, the under-extrusion might be affecting layer one along with other layers (could also be a layer one tuning issue). This changes the logic for finding the cause. The bridging issue you showed is something else, probably unrelated to extrusion rates and best ignored for now.

The 1.06 multiplier setting looks okay - but the top surface should be smooth; your fingernail should feel the extrusions, but not catch on any ridges. 1.06 is higher than I'd expect is needed for a new printer, and 1.10 seems unrealistically high. Did Prusa have you try 1.04 or 1.05? Changing extrusion ratio for different filaments is within the normal expected use envelope - as is adjusting for actual filament diameter (two ways to accomplish about the same thing).

You might try printing with 1.04 or 1.05 for a while and see how the parts turn out. As a data point, there are times you'll need to increase or even decrease flow midprint because of print weirdness.

And a last question: where is Prusa having you change the extrusion multiplier? It should be in the filament profile. Or are they having you change the printer profile gcode (the only place 95% is used)?

RE: Underextrusion on internal layers?

Tim, thanks again for your suggestion!

I realized that the first time Prusa support asked me to print with 1.05 they asked to do it in the printer's menu (flow rate) and to bring it from 95 to 105. And that didn't work. So apparently, i haven't tried printing with coefficients lower than 1.06 when set through the slicer software. Well, with one exception - i tried that with a calibration cube, where I measured the coefficient should be 1.0345 but that wasn't enough.

So, what I did is I tried printing my test square, where I can always repro the issue, with coefficients of 1.03, 1.04 and 1.05.

What i got is 1.03 isn't enough, but close. 1.04 is good, but has slight overextrusion. 1.05 is too much.

On a different note, i also tried printing with a higher temps (+10 and +20 C) with & without extrusion multipliers. Unfortunately, with the filament I have it causes so much stringing, that it ruins my prints quite often 🙁

Perhaps the answer for me is to use a multiplier close to 1.04, perhaps a tiny bit smaller??

I also noticed, that printing at different layer height seemingly require slightly different coefficients. Same coefficient causes slightly different amount of over extrusion for 0.15 and 0.2mm. Is that typical?

I'm almost 2/3 into my first PLA roll, spent just on these calibration cubes and test squares. I hope my next roll won't need that much tuning before I can actually use it.

RE: Underextrusion on internal layers?

@doctorshtein

Call that first roll the cost of building and calibrating your printer. As a forward looking statement: I've found cheap filament to print just as well as expensive filament - so don't be afraid to try $15 a roll products. Just don't buy 20 rolls until you've run enough to know it works for your setup. And, after a few rolls, you'll know what looks right for layer one and will just start printing.

So, what I did is I tried printing my test square, where I can always repro the issue, with coefficients of 1.03, 1.04 and 1.05.

Where are you changing the extrusion multiplier for those tests - Printer menu or Slicer filament setting? I assume you've figured out how to modify a profile and save it - makes slicing easier and more consistent than trying to remember everything that worked.

And yes, layer heights can affect extrusion. Usually, lower heights - under 0.1 mm - is where it gets significant and you might need to change settings - it's a Slic3r internals thing. So Prusa has gcode in profiles that does some of this automatically. Or if you play with extrusion widths and try to push a lot of filament. Fine tuning a print is something that can bury you in minutia. Flow - extrusion multiplier - volumetric flow limit - filament diameter. Think tip of the iceberg.

@bobstro has a great resource library he's been building up on his ttlexceeded web page. http://projects.ttlexceeded.com

As for what setting to use - at some point it comes down to personal preference. My layer one - my print sheets - have enough variation from center to corners I usually over extrude corners a bit when I have set 1.0 in the middle. I'd rather over-extrude layer one than under-extrude.

When I slice at different layer heights, I generally just use the defaults (I do have a few settings that are different, but I have those in my filament profile). So I never worry about multipliers until I am printing: I'll sometimes add or subtract a few percent at the printer (Tune-Flow) because the layer one seems to be going down thin or thick. Some people dial in flow based on measured filament diameter before they slice - proactive. I never know what filament I am going to use when I slice - so I tend to be reactive.

Some of this comes down to whether you are making art, or a utility part. Miniatures for a diorama need to be fairly clean prints. A hose adapter can be pretty ugly as long as the threads work. I've given up printing some projects because after a while you learn an FDM printed just doesn't do well enough. The other side of that coin is I've designed and made a lot of stuff I needed spur of the moment that would have required a trip to the department or hardware store. I'm constantly amazed - how did I get along without a 3d printer?

RE: Underextrusion on internal layers?

Where are you changing the extrusion multiplier for those tests - Printer menu or Slicer filament setting?

I did all the changes in the slicer for my latest tests. And yes, profiles help a lot!

Thanks again for all the wisdom!

RE: Underextrusion on internal layers?

Hello everybody!

Just yet another update. I recently got a bunch of replacement parts from Prusa: nozzle, heatbreak, bondtech gears and a print fan.

I replaced them one by one with calibrations and test prints in between. Unfortunately, nothing helped yet.

But the reason I post is not just that. I found an interesting thing while replacing the heatbreak. There was a bulb of filament stuck between the nozzle and the heatbreak inside the heaterblock. And it was quite big! Perhaps 1.5mm high (see the picture attached).

I'm really confused how could it get there, cause the nozzle and heatbreak are supposed to be touching each other (IIUC) ?, and they are tightened while its hot, so I would expect that blob to be squished, yet it was not.

Anyway, after removing the blob, and getting a new heatbreak and new nozzle, it started printing just fine, but then went back to underextruding within ~1 hour of printing time :(.

Will appreciate your opinions about that blob of filament.

RE: Underextrusion on internal layers?

Hello DoctorShtein,

I am experiencing this exact problem now, and dont know what the heck to do about it!

Did you fix it, and if you did, how?

I've tried all kinds of things!

RE: Underextrusion on internal layers?

Hi @DoctorShtein

Did you get this resolved?