PTFE tube damaged after ~200 hours of printing?

So we just got a new Prusa i3 mk3. This is our first printer, so I'm not super experienced. I had a print fail, it might have been from a power loss, and it said to unload the filament. The filament was stuck and it indicated to manually open the idler pulley and remove the filament.

First issue, I wasn't sure how to open the idler pulley. I figured it out, I think, by unscrewing the two spring tensioned screws on the left side of the drive. Having a specific instruction on how to do this would help.

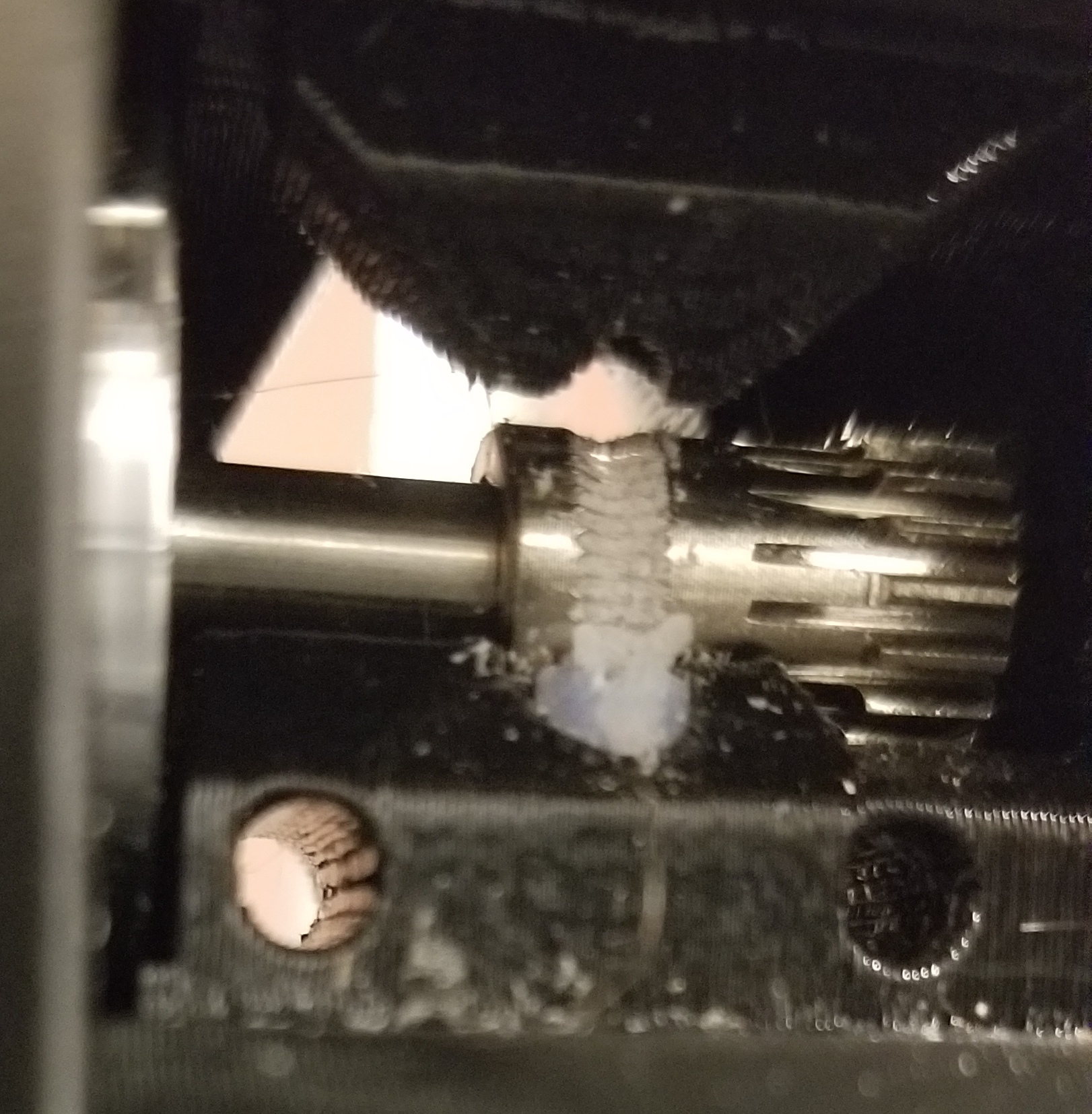

Second issue, a part fell out and I don't know where it goes. Here's a picture

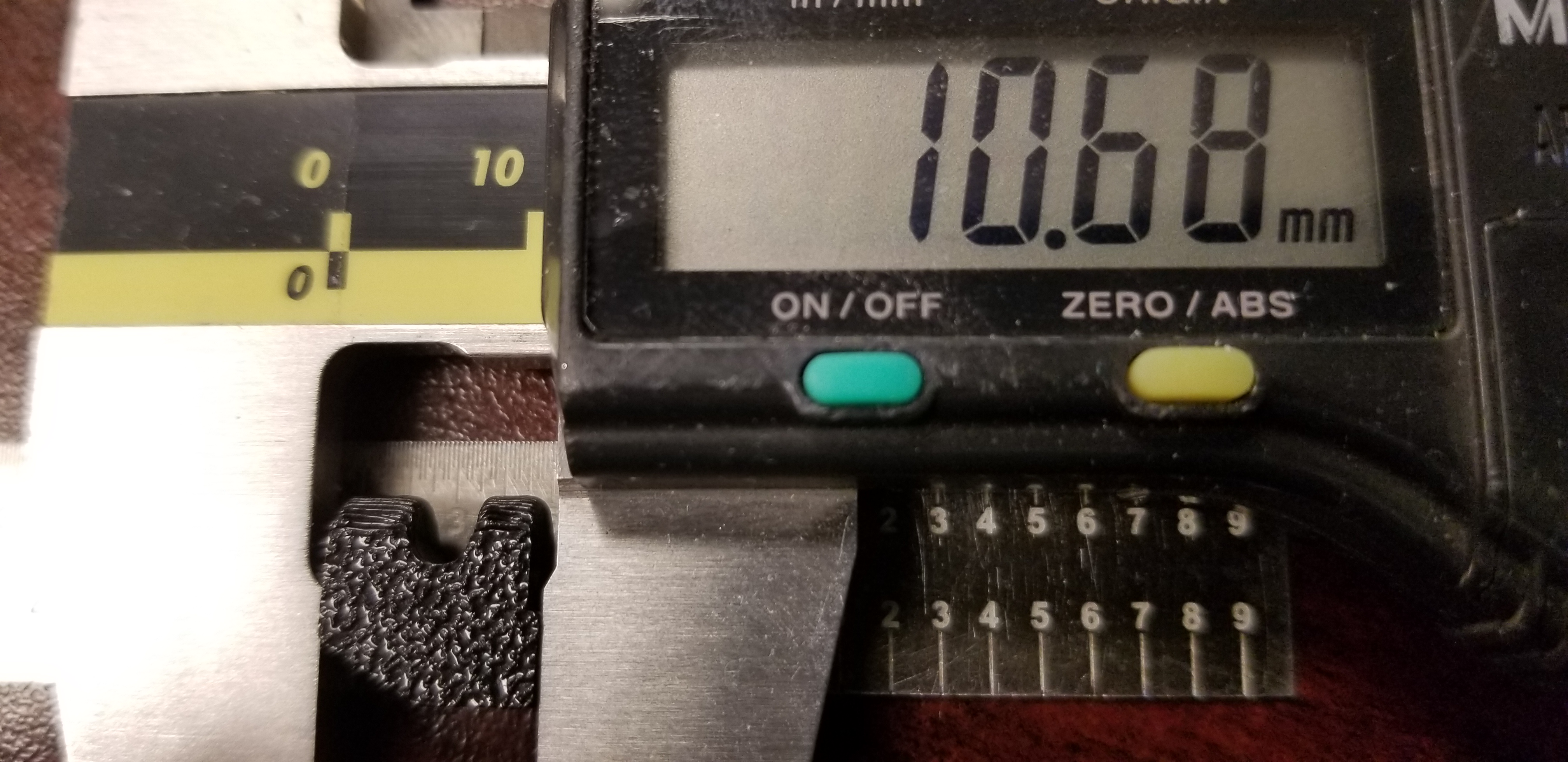

Third issue, It looks like the top of the PTFE tube got chewed up by the filament gears. here's a picture. I'm not positive, I was printing with a white PLA so it could be that, but

So I cleaned up the area and was able to load filament and am trying the failed print again.

If you could guide me and tell me if I did something wrong, make suggestions about what I should be looking for what I should do it would be appreciated.

thanks,

-Kirby

Re: PTFE tube damaged after ~200 hours of printing?

Hi Kirby,

the black plastic plug, is terribly fiddle. I made a bigger version because the original is hard to manage with long fingernails...

it fills the space where you access the filament sensor cleaning hole in the extruder body.

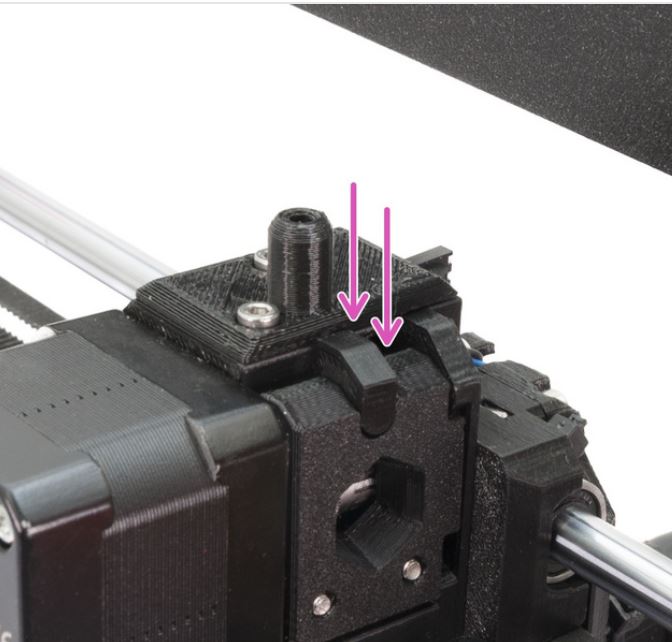

^^^Like this^^^

the PTFE looks a bit mangled... did the print work ok?

you may be wise to replace the PTFE... get the replacement tube before you take the extruder apart...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: PTFE tube damaged after ~200 hours of printing?

Yes, that's it. Be careful when you re-tighten as you don't want to over-tighten these screws. The correct tightening varies a bit by material, but generally the screws extend a bit less than 1mm when I've got mine set.

[...] First issue, I wasn't sure how to open the idler pulley. I figured it out, I think, by unscrewing the two spring tensioned screws on the left side of the drive. Having a specific instruction on how to do this would help.

Second issue, a part fell out and I don't know where it goes. Here's a picture

That is this guy.

20181012_063116.jpg

Third issue, It looks like the top of the PTFE tube got chewed up by the filament gears. here's a picture. I'm not positive, I was printing with a white PLA so it could be that

It's hard to say for sure from the pic. Be sure you're looking at the PTFE tube and not some filament stuck below it. Filament can break off below the pulley but above the hotend, getting stuck in the PTFE tube. Clearing that is not a big deal and does not require disassembly.

So I cleaned up the area and was able to load filament and am trying the failed print again.

If you were able to load and extrude filament, that argues against there being anything broken off. Do watch for extrusion issues.

I'd suggest reading up on doing cold pulls if you haven't already. They're helpful for avoiding jams over time.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: PTFE tube damaged after ~200 hours of printing?

Thanks Joan and Bobstro,

I have PTFE on order from matterhackers. Went to Prusa's website and it was $0.70, plus $27 in shipping. Hey Josef, would you like to set up a US distributor????

I may replace it next week when I install a ruby nozzle for abrasive filament.

Is there a method for determining the correct tension to put on the hobbed pulleys? I think I have it looser now than how it came out of the box. I'm guessing harder materials need less tension when unloaded.

I think I can do a cold pull now. I was wanting to do this before, but didn't know how to manually release the hobbed pulley. If I need to now I'm ready and may just for practice after this print is finished.

Best Regards,

-Kirby

Re: PTFE tube damaged after ~200 hours of printing?

check to see if the PTFE tube is locked into place, mine came loose and about did the same thing.

tension on the pulley for me seems to be with filament in, the screw head sticks out just about a mm

I have a Prusa,therefore I research.

Re: PTFE tube damaged after ~200 hours of printing?

I just tighten 'em down to a bit less than 1mm protruding and am not having any feed or temp issues. I think there is a formal guide out there, but I don't have a link.

[...] Is there a method for determining the correct tension to put on the hobbed pulleys? I think I have it looser now than how it came out of the box. I'm guessing harder materials need less tension when unloaded.

I think I can do a cold pull now. I was wanting to do this before, but didn't know how to manually release the hobbed pulley. If I need to now I'm ready and may just for practice after this print is finished.

I make a point of doing cold pulls before every nozzle change, and when switching between filament types. I haven't had a jam since I started doing this. I recommend using cleaning filament. It's quite sticky, so good at pulling crud out of the hotend and nozzle, and works over a wide range of temps, so if you leave a little in, it won't jam up on your next PLA print. My notes on doing a cold pull are here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: PTFE tube damaged after ~200 hours of printing?

That length on the ptf tube is critical as is carefully coning the top of it to receive the filament coming off of the drive gear... two way to cone it the easy way is with a dead sharp fine point exacto blade but use care to leave no roughness or bits of plastic in the cone

There is a blueprint on the Prusa pages that shows the tube with its measurements

https://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+MK2-S+MK2.5+and+MK3/500?lang=en

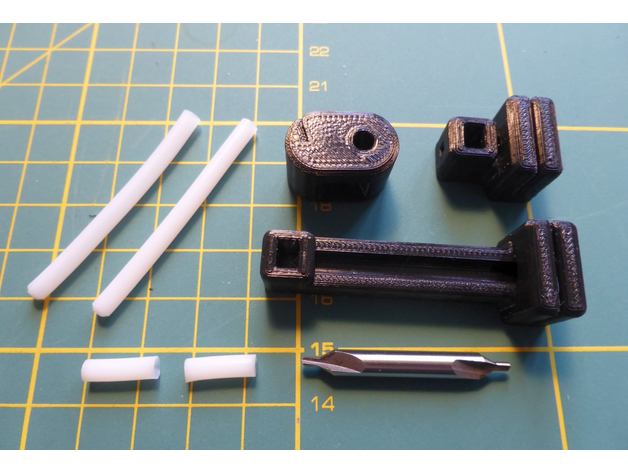

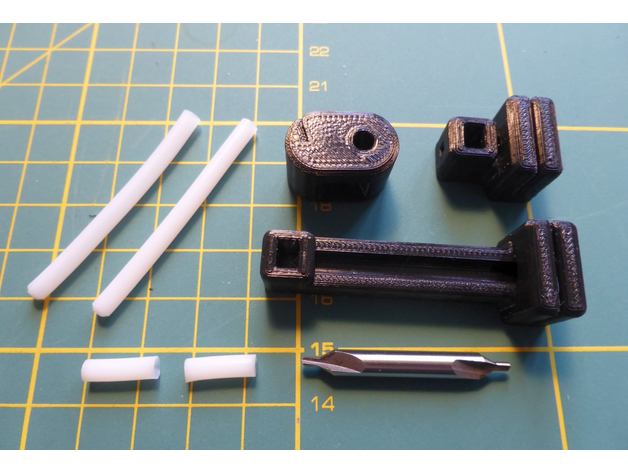

Area51 has this really nice jig to make this a lot easier

When upgrading my MK3 to R3 I changed PTFE tubes as well.

Decided to make a jig for the job:

P1120132 - Thingiverse.jpg

Link to Thingiverse PTFE Tool Jig

Besides the printed parts you will need a hobby knife with 9mm blade and a 60 degree center drill.

BTW your taper (chamfer) looks good 😀

us this with the Prusa instructions page linked above

Re: PTFE tube damaged after ~200 hours of printing?

I make a point of doing cold pulls before every nozzle change,

😕 This seems counter-intuitive to me. I would think it would be easier to clean a nozzle not attached to the printer. Likewise, I would think the rest of the filament path would be easier to clear/clean without the nozzle in the way.

What am I missing?

That's "MISTER Old Fart" to you!

Re: PTFE tube damaged after ~200 hours of printing?

It's a lot easier to get filament off and out when it's molten. I raise Z up, run cleaning filament through, reset and let it cool with the filament still in place. Once it's below 90C, I set the nozzle temp to 250C or higher, do the pull at 90C, then give the nozzle a brushing at 250C right before I remove it. If the pull goes well, I can see daylight through the nozzle before I pack it away. (Full notes here if you'd like more detail.)

[...] This seems counter-intuitive to me. I would think it would be easier to clean a nozzle not attached to the printer.

I still give the tips a buff before mounting new ones, but I like knowing they're clear before storing them.

Likewise, I would think the rest of the filament path would be easier to clear/clean without the nozzle in the way.

Other than cleaning out the extruder gears now and then and blasting the filament sensor, I haven't had to do any real work on the feed path. The cleaning filament clears out the hotend as well as the nozzle of course. If I have a jam, I'll drop a 1.5mm rod down through the extruder or up the nozzle opening, depending on the jam.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: PTFE tube damaged after ~200 hours of printing?

Area51 has this really nice jig to make this a lot easier

When upgrading my MK3 to R3 I changed PTFE tubes as well.

Decided to make a jig for the job:

P1120132 - Thingiverse.jpg

Link to Thingiverse PTFE Tool Jig

Besides the printed parts you will need a hobby knife with 9mm blade and a 60 degree center drill.

BTW your taper (chamfer) looks good 😀

and this is Prusa's instructions for this

https://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+MK2-S+MK2.5+and+MK3/500#_ga=2.200380013.230346844.1537234912-1444735114.1531445689&_gac=1.116397556.1537620320.Cj0KCQjwrZLdBRCmARIsAFBZllEWvLqlMjoiF8C6veDI7wDGIbr7C-6SG_vHzdOcSGfe6dAQtFpHsioaAgB0EALw_wcB

RE: PTFE tube damaged after ~200 hours of printing?

> Went to Prusa's website and it was $0.70, plus $27 in shipping. Hey Josef, would you like to set up a US distributor????

Good point. Does anyone know why he hasn't taken this most obvious step? If he made ordering easy, I would regularly purchase from them (I have ten printers and spend considerably more on filament than printers), but their filament -- although excellent quality -- isn't sufficiently better than competitors to compensate for the hassles of ordering direct: after my initial printer + filament + accessories order, I was beset with customs forms and steep extra fees collected by FedEx (beyond the free shipping then in effect). Now that Bambu Lab and other competitors are innovating at breathtaking speed, Prusa should make ordering as easy as possible -- but they don't. My best guess: their hardheadedness.

RE:

I believe Printed Solid, Is Prusa's US Distributor.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PTFE tube damaged after ~200 hours of printing?

That option wasn’t available to me when I ordered my printer, filament, accessories, and it very likely wasn’t available when I needed two replacement thermistors, which I had to wait — and wait — for after wasting many hours “proving” to Prusa’s tech support that the problem was indeed a bad thermistor: something obvious to me with decades of electronics experience.

Prusa’s goal is to have as many happy customers as possible, but I was exasperated virtually every time I had to contact tech support. I was also exasperated when my Prusa printer encased its hotend for the third time, with the last time unfortunately being an absolutely massive ball of PETG that took weeks of work to remove and some replacement parts. That needless hassle could have been obviated if Prusa implemented what strikes me as obvious ways to instantly stop printing if a blob of death begins to develop. My Mk 3 S+ could have — but didn’t — include a simple, robust mechanical sensor to safeguard the printer.

In dealing with Prusa reps, I repeatedly got the impression that if users have better ideas, Prusa isn’t interested in hearing about them. So after purchasing my first 3-D printer, a Prusa, the next nine were not Prusa. If Prusa was receptive to user input, customers could print PETG and TPU on smooth PEI sheets with very easy part removal (as opposed to PETG sticking like glue, quickly ruining my smooth PEI sheet) — as just one of many examples illustrating how Prusa does less than it could to impress users.