Intermittent Printing Issues

Greetings from Detroit!

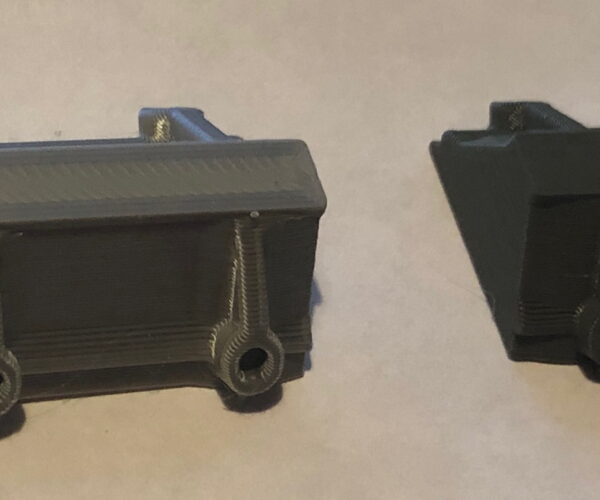

I'm having an intermittent issue printing a specific feature on one of my models that has been plaguing me for months.

Hoping someone out there can offer some insight.

This feature is 8h into a 16h print, so I made a small test with only this part so I could test some changes more efficiently.

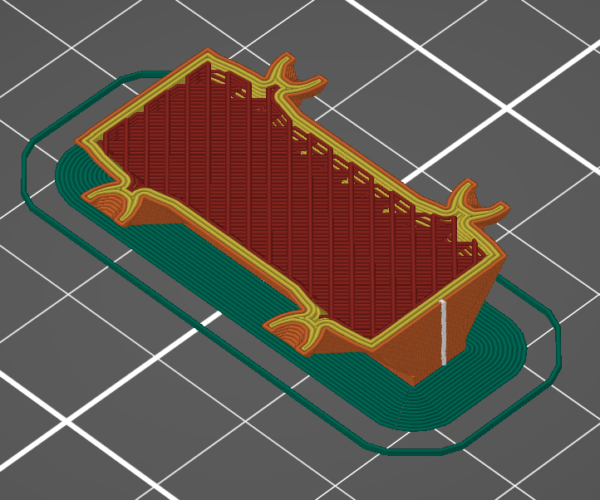

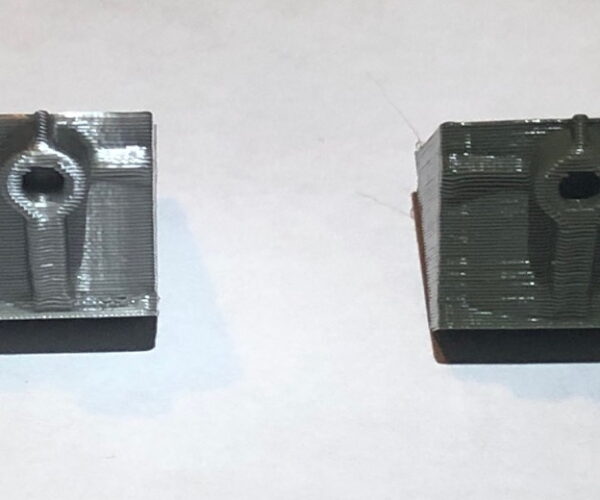

I've looked at the tool path in PrusaSlicer (2.5) and they are identical on both sides of the model and look pretty clean to me.

I have moved all seams away from these features to make sure the travel is uninterrupted.

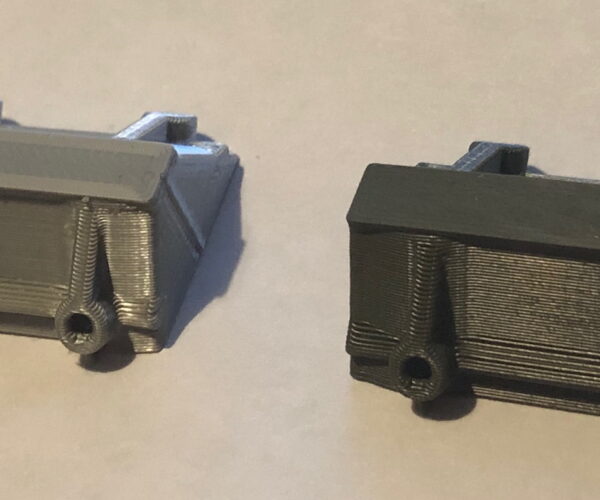

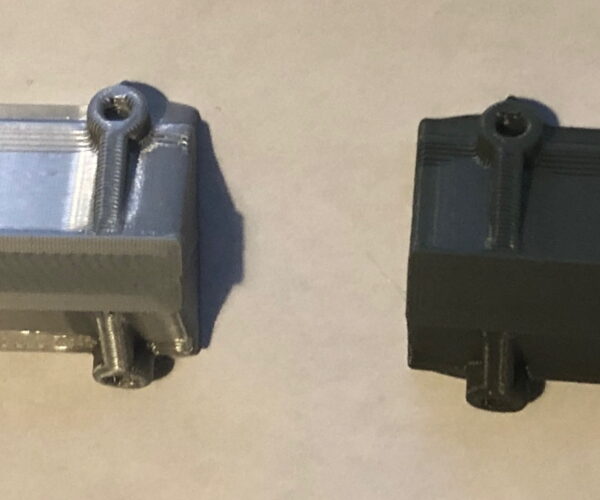

Since this is a 50 degree overhang and the perimeter seems to be curling, cooling is my main suspect.

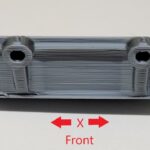

I tried changing the orientation of the model to see if I could influence the results:

Better in the Y direction but still not great. When I tried printing the full model the results were worse than the test.

The cooling fan is running at full speed and there seems to be plenty of airflow.

I've also replaced the cooling fan and tried an upgraded duct with no success.

Machine is calibrated and belts are properly tensioned. X and Y carriages move smoothly.

Hot end temperature has been verified against a calibrated master gauge. Temps are fairly accurate and stable.

I'm printing with silk silver PLA at 205C. Anything lower and clogging becomes an issue with this filament. Nozzle is 0.4mm Micro Swiss.

It's puzzling that the model will print successfully for weeks and then suddenly start producing this issue. And again this prints fine on my other machines.

This issues has been resolved (or so I thought) a couple of times only to re-emerge later. Once it starts it's consistently bad.

Any feedback would be appreciated!

Thank you,

David

Best Answer by Solidev:

Rotated part 90 degrees so the mounts are on the sides as opposed to front and rear and they look good again.

Seems like I have intermittent trouble cooling overhangs on the side opposite the fan.

I've tried rotating before and the result wasn't great so I'm not 100% clear on the root cause, but all 3 are running again.

Appreciate all of the help guys, good people in here!

this is a 50 degree overhang and the perimeter seems to be curling

That's steep for silk PLA, how does it print with plain PLA?

You could try slowing the print in that area.

Cheerio,

RE: Intermittent Printing Issues

Also you could try turning the cooling down. While that may sound counter intuitive it’s the cooling rapidly on those thin slopes areas that causes them to curl upwards.

would you mind attaching your zipped up project for your test piece please. That way we can get a proper look at everything.

RE: Intermittent Printing Issues

If you can't improve part cooling any further, print slower, and if that doesn't help enough, print even slower. You can adjust live with the dial, just reduce the global speed. For challening overhangs I have seen that printing at 50% standard quality setting speeds can resolve overhang issues, if it doesn't try 25%. Also, orient the most challenging overhang side towards the front of the printer where cooling is the best.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Intermittent Printing Issues

I have the same issue with plain PLA, but again, only on this printer.

I did get a better result by slowing the perimeter speed, but it adds quite a bit of time to an already long print. I print about a dozen of these each week so the hours really add up. If I apply the speed changes only to these layers, I think I will see a change in the finish with the silk PLA.

I have 2 other MK3S+ printers that are able to print this perfectly, so I don't think I'm exceeding the capability of the machine. Something must be off with this one.

this is a 50 degree overhang and the perimeter seems to be curling

That's steep for silk PLA, how does it print with plain PLA?

You could try slowing the print in that area.

Cheerio,

RE:

I will try that. I did try increasing the print temperature from 205 to 210 and 215 and still no luck.

The test piece is attached if you want to try it out on your machine. I really appreciate the help!

Also you could try turning the cooling down. While that may sound counter intuitive it’s the cooling rapidly on those thin slopes areas that causes them to curl upwards.

would you mind attaching your zipped up project for your test piece please. That way we can get a proper look at everything.

RE: Intermittent Printing Issues

Thanks for attaching the test part file.

I opened it up and changed the printer for my normal profile and the filament profile to match what was already loaded in the printer. Some grey rPLA from 3djake. Its a recycled filament that has a 200-220 print temp on it. So my 215 temp with a steel nozzle is in the middle of the range, equivalent to 210.

Some Notes on my physical setup-

My printer started off as a MK3 (non S). I've since rebuilt the extruder to use a 3:1 ratio geared system (Bunny & Bear) as that mod still makes use of the old style filament sensor. The cooling fan is basically pretty much the same from the Mk3S though. I dont beleive the extruder has any relevence in this case though.

There are also changes to the printer profile, like some start gcode based on Bobstro's to handle preheating the old style pinda to a known set temp before it does a mesh level. This gives me very consisten first layers and is why the brim on this is superflouous. I also usually have retract on layer change and wipe while retracting turned off. I just dont need to do those.

The extruder is fitted with a 0.4mm E3D nozzle X currently so I have to tweak my temps ~5 degrees higher on my filament profiles. One thing you may notice on the filament profiles is that rather than alter the extrusion multiplier (like your original has) I tune mine by accurising the filament diameter. I measure the real filament and plug those into the filament diameter field. This usually means that the EM does not need changing. Every calculation for the amount of filament extruded starts with the filament diameter, if its off then all the calculations are off by the same amount.

I also changed a few settings in your print profile but nothing major, basically turned off the brim (part doesn't need it with a clean sheet and a properly dialled in live Z), reduced the skirt etc. I think the biggest change I made was to change infill from rectilinear to cubic. I dislike rectilinear as its a 'crossing' infill. It hits previous lines on the same layer where it crosses over them. Cubic is nice straight lines, doesn't shake the printer around like gyroid and has a very similar strength to weight ratio as gyroid.

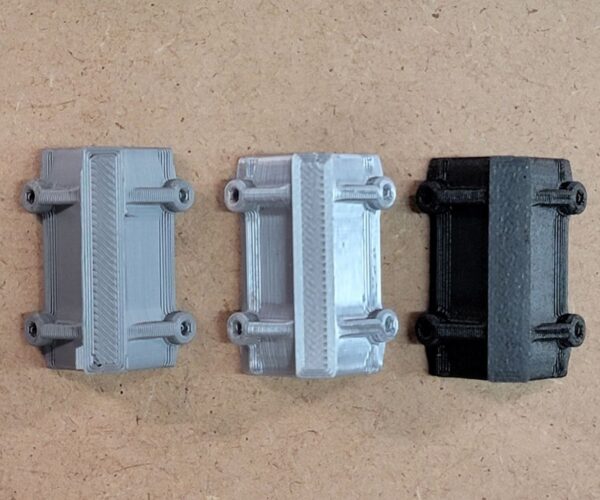

Part was printed in the orientation from your project. Both 'front' and 'back' look equally the same, the cooling from the front does not make an appreciable difference as far as I can see.

I then printed a second one with some silver silk I've used quite a lot of. MKOEM from amazon. I just loaded my usual filament profile for that. For this filament I print it at 230. The filament is rated for 205-235 degrees. So 230 is equivalent of 225, again in the middle but towards the hotter end of the scale. I would never try and print it at the lower end. The print in person isn't 'quite' as tidy as the rPLA but I don't think its bad by any means. None of the issues you picture.

Now my pics aren't as good as yours 🙂

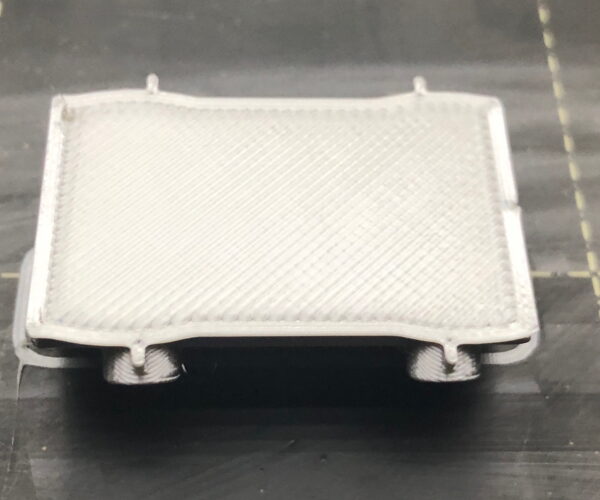

Silk part on the bed still.

Here you can see your painted on seam, so the part closest to the camera was the rear of the print. No real difference.

I've attached a zip with both projects, the rPLA and the silk print versions.

After looking closer at your pictures I'm also concerned about the big extrusion loop artefacts you have a few layers up. A behaving extruder should not be doing that.

I suspect you are over extruding slightly though.

You mention using a microswiss nozzle ? Was there any reason to use one with a different geometry to the E3D which is designed specifically for the extruder ?

I've got a microswiss hotend on my cr10 and it has never printed as well as my Mk3. Now I don't know if that's the cr10 build or the extruder, or both. First thing I'd be trying is going back to an e3d nozzle to see if it makes any difference.

RE: Intermittent Printing Issues

Printer #2 now acting up. Front side. Overture Matte Black PLA. How??

RE: Intermittent Printing Issues

Thanks for attaching the test part file.

I opened it up and changed the printer for my normal profile and the filament profile to match what was already loaded in the printer. Some grey rPLA from 3djake. Its a recycled filament that has a 200-220 print temp on it. So my 215 temp with a steel nozzle is in the middle of the range, equivalent to 210.

Some Notes on my physical setup-

My printer started off as a MK3 (non S). I've since rebuilt the extruder to use a 3:1 ratio geared system (Bunny & Bear) as that mod still makes use of the old style filament sensor. The cooling fan is basically pretty much the same from the Mk3S though. I dont beleive the extruder has any relevence in this case though.

There are also changes to the printer profile, like some start gcode based on Bobstro's to handle preheating the old style pinda to a known set temp before it does a mesh level. This gives me very consisten first layers and is why the brim on this is superflouous. I also usually have retract on layer change and wipe while retracting turned off. I just dont need to do those.

The extruder is fitted with a 0.4mm E3D nozzle X currently so I have to tweak my temps ~5 degrees higher on my filament profiles. One thing you may notice on the filament profiles is that rather than alter the extrusion multiplier (like your original has) I tune mine by accurising the filament diameter. I measure the real filament and plug those into the filament diameter field. This usually means that the EM does not need changing. Every calculation for the amount of filament extruded starts with the filament diameter, if its off then all the calculations are off by the same amount.

I also changed a few settings in your print profile but nothing major, basically turned off the brim (part doesn't need it with a clean sheet and a properly dialled in live Z), reduced the skirt etc. I think the biggest change I made was to change infill from rectilinear to cubic. I dislike rectilinear as its a 'crossing' infill. It hits previous lines on the same layer where it crosses over them. Cubic is nice straight lines, doesn't shake the printer around like gyroid and has a very similar strength to weight ratio as gyroid.

Part was printed in the orientation from your project. Both 'front' and 'back' look equally the same, the cooling from the front does not make an appreciable difference as far as I can see.

I then printed a second one with some silver silk I've used quite a lot of. MKOEM from amazon. I just loaded my usual filament profile for that. For this filament I print it at 230. The filament is rated for 205-235 degrees. So 230 is equivalent of 225, again in the middle but towards the hotter end of the scale. I would never try and print it at the lower end. The print in person isn't 'quite' as tidy as the rPLA but I don't think its bad by any means. None of the issues you picture.

Now my pics aren't as good as yours 🙂

Silk part on the bed still.

Here you can see your painted on seam, so the part closest to the camera was the rear of the print. No real difference.

I've attached a zip with both projects, the rPLA and the silk print versions.

After looking closer at your pictures I'm also concerned about the big extrusion loop artefacts you have a few layers up. A behaving extruder should not be doing that.

I suspect you are over extruding slightly though.You mention using a microswiss nozzle ? Was there any reason to use one with a different geometry to the E3D which is designed specifically for the extruder ?

I've got a microswiss hotend on my cr10 and it has never printed as well as my Mk3. Now I don't know if that's the cr10 build or the extruder, or both. First thing I'd be trying is going back to an e3d nozzle to see if it makes any difference.

Thanks for all of the feedback!

I just printed your silk file. Front is clean, rear is messy.

I really don't think it's an issue with the gcode because I've printed hundreds that have come out perfectly. And to have 4 of the same feature and one to be randomly messy when the others are fine? Now the issue is present on a second printer. I'm down to 1 capable printer now, which is a new factory assembled MK3S+

Regarding the extrusion loop artifacts, that was just a detached skirt that got into the base of the print. I was running through a bunch of iterations and wasn't cleaning the bed in between.

I changed my nozzle back to the original one from Prusa and that didn't make a difference either. I'm at a loss.

RE: Intermittent Printing Issues

Rotated part 90 degrees so the mounts are on the sides as opposed to front and rear and they look good again.

Seems like I have intermittent trouble cooling overhangs on the side opposite the fan.

I've tried rotating before and the result wasn't great so I'm not 100% clear on the root cause, but all 3 are running again.

Appreciate all of the help guys, good people in here!