First layer woes.

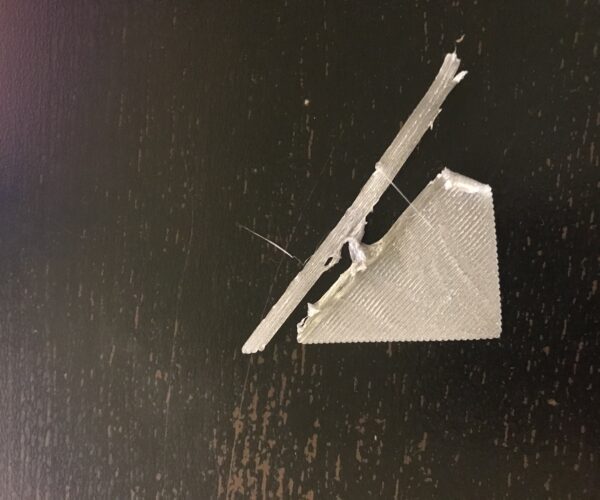

I have had my prusa mk3s for about a month now. It suddenly developed a problem that I cannot seem to zero in on or solve that has rendered the printer useless. My first layer calibration looks perfect with exception to the final rectangle it prints before completing the process. The rectangle looks as though that with each pass it overlaps the previous pass slightly. This causes the corners to curl sometimes but almost 100% of the time it causes odd striations on the printed material. This becomes additive when trying to print a job and eventually, due to the added height, it get’s hung on the nozzle and drags the part around just shooting material out aimlessly. It also seems to be intermittent but the z height calibration print always looks like the pic. I am hoping someone could point me in the right direction on what to check next.

I have had my prusa mk3s for about a month now. It suddenly developed a problem that I cannot seem to zero in on or solve that has rendered the printer useless. My first layer calibration looks perfect with exception to the final rectangle it prints before completing the process. The rectangle looks as though that with each pass it overlaps the previous pass slightly. This causes the corners to curl sometimes but almost 100% of the time it causes odd striations on the printed material. This becomes additive when trying to print a job and eventually, due to the added height, it get’s hung on the nozzle and drags the part around just shooting material out aimlessly. It also seems to be intermittent but the z height calibration print always looks like the pic. I am hoping someone could point me in the right direction on what to check next.

Thus far I have checked the following:

Both x and y axis belts checked and tightened

Filament sensor showing a 1 in the support console - still not 100% fixed but I plan on printing the shim once the printer works again. For now I have a temporary shim in place that seems to fix the sensor issue most of the time.

Replaced the nozzle with e3d v6 .4mm(same as shipped)

Flashed the firmware.

Reset the z height close to 20 times now to see what if any effect changing the z height made. This far I have no repeatable results from a wide range of z heights.

Lowered the operating temperature of the nozzle. I only did this temporarily because I have seen on other sites that PLA is often printed at 200/195c and prusa has it set to 215/210c so I thought I would try it. It is back to 215/210c now.

I am new to 3D printing as a hobby and this has really stumped me. One more change was the introduction of some different filament. I bought some Sunlu PLA and it printed flawlessly for about 5 large prints until this problem surfaced. However I switched back to the PLA shipped with my printer kit before I started troubleshooting and am experiencing the same issue.

Thanks in advance!

RE: First layer woes.

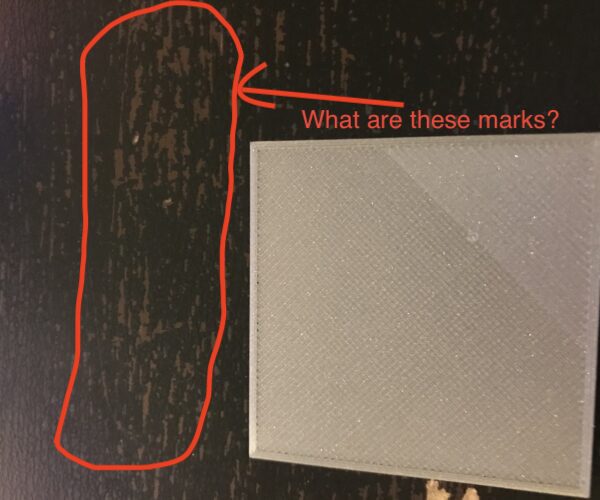

Can you add a photo showing the rest of the first layer calibration? It's hard to tell from this photo, but looks like the first layer is low.

RE: First layer woes.

SCRUB your build plate with unscented detergent and lots of hot water. Dry with a clean paper towel. Use no IPA for next step.

Don't use the calibration square built in the firmware. Print a decent 2" or so circle or square, and adjust Z while it is printing.

See:

RE: First layer woes.

And when robert says hot he really means HOT, as in use waterproof oven gloves to hold the sheet at the edges.

I had very frustrating adhesion problems until I read properly and used hot water, everything good as gold since then.

RE: First layer woes.

@robert-rmm200

I will give this a shot tonight.. sorry I can’t get to it faster. I have cleaned the sheet with hot water and mild detergent already and have also used the second one that came with my kit but I have used a microfiber towel and 91% isopropyl before each print even directly after cleaning with hot water and detergent or using the second sheet that was brand new. Do I need to be cleaning the sheet between each print with hot water and scentless detergent? Is there any reason to believe that the alcohol or the towel choice could cause this?

RE: First layer woes.

@gkmakeit

I will add additional photos as soon as I can 🙂

RE: First layer woes.

Skip the IPA for now. It is suspect. Get a good Z set just using detergent and hot water scrub.

I give mine the detergent scrub maybe monthly, as needed.

IPA after every couple of prints. But it is 99%, in a squeeze bottle, and I trust it.

RE: First layer woes.

this is where I started. -1.695

-1.9 this was odd since it appeared to print half off the square pretty well then almost went down to nothing.

-1.8

-1.7 getting there

-1.65 even closer

-1.625 looks pretty good. At this point I switched back to my white Sunlu PLA and then the problems started rolling in. So I know the filament is not good at least not with out of the box prusa PLA settings. I started an identical print but it started to curl on me so I stopped and it and tried a Z-calibration. Almost none of it had what I would call good bed adhesion. I swapped back to the prusament and I ran another 10 or so prints of the 2x2 square and everything seemed to be back in order. Then I tried to print something with a circle and some odd angles. and this.....

I have tried to start the print over and over again thinking that there might be some of the bad filament left in the hotend or something.. I finally got a print to start ok so I am going to let it finish. I will update more after it finishes or if it fails. I am really hoping that it was just the bad filament. I will update soon.

RE: First layer woes.

@gkmakeit

that is my computer desk. I took the pics after removing the parts from the build plate. I have some of them on the build plate but they didn't turn out as well. what you're seeing is 12 years of wear on an IKEA desk lol.

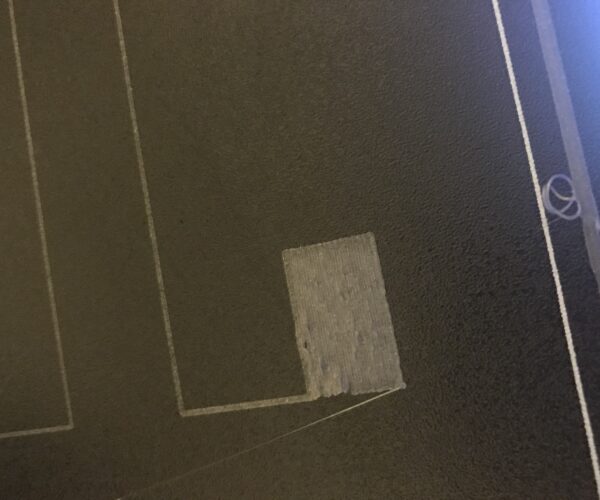

edit: the last photo is of a nut and bolt so the whole is supposed to be there.

RE: First layer woes.

The desk! lol

I don't know if its the angle of the photo, but on that last one if nothing looks "square" or even on the parts. Even the skirt looks closer to the part on some sides compared to the others. Should that 6 sided part be the same around all 6 sides?

RE: First layer woes.

@gkmakeit

The nut's hole is offset because it makes the thread pattern so it appears to be miss-aligned but it is actually in the right spot. The photo is also not taken directly overhead so it is skewing the lines a little to make the skirt look uneven. Ultimately it was a bad print from the start so there is likely a lot of it that is off in one way or another. The print I am running of the same parts looks significantly better I will post photos of it when it finishes/fails.

RE: First layer woes.

I have to say - your Z was getting better. You are getting the hang of it. Live Adjust while it is printing really helps.

RE: First layer woes.

Looks like everything is back to normal. Thank you so much for the help!! Live Z adjust is the way to go. It was a lot easier to see how well the first layer was doing on the 2x2 square than the z height calibration, it really lets you dial it in. I also know that either my settings were bad for the Sunlu PLA or the filament itself is bad. So for now I am going to just not use that filament until I can determine if it was me or the product.

RE: First layer woes.

Nice job!

You know pretty quickly if a bolt and nut printed correctly.

Decent test for how good your printer is.

RE: First layer woes.

Glad I read this post was about to disassemble and reassemble the damn thing, this post saved my day 👍

Not sure why that cleaning stuff is not working but I am never going to use that crap again