Excessive Stringing, Surface Bumps and Burnt Filament in prints

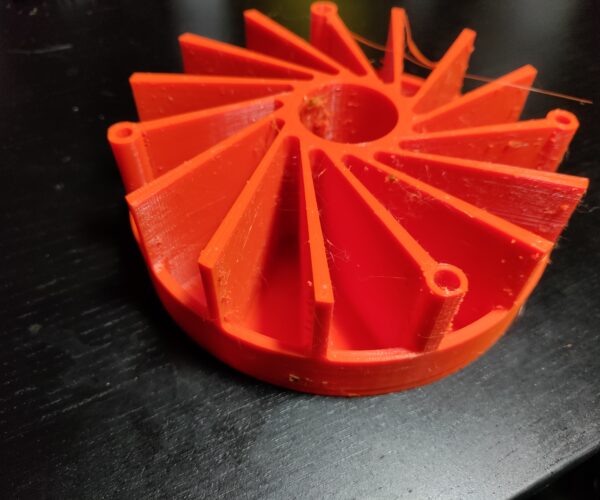

Hello! I am using a Prusa MK3S+ printer with Prusament PETG. When printing parts on the "0.20 Quality" (or higher quality) settings using the default prusament petg and MK3S+ presets, I get prints that look really bad with a lot of stringing, surface bumps, and burnt filament dropping into the prints, as you can see in the provided images.

In an attempt to fix this I switched to using prusament (no significant change), and I replaced the heater block, nozzle, and heatbreak. The print below was made immediately after replacing the nozzle, block, and heatbreak, calibrating, and printing a test benchy, so the nozzle and block were clean starting out the print. After the print the bottom of the block and nozzle are very messy with burnt filament.

Does anyone have suggestions on how to improve the quality of my prints from their current state? Is it normal to have to do a ton of sanding and filing to get prints to be smooth after printing? Frankly, I'm jealous of all of the beautiful prints a lot of others seem to be able to get with the same hardware and I'm curious if there is something fundamental that I'm doing wrong.

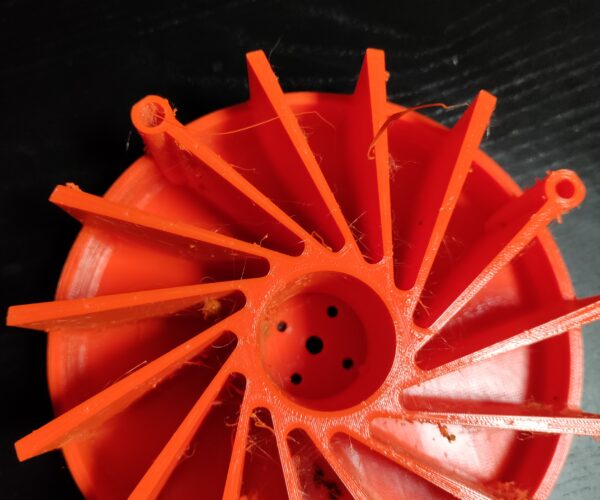

This is the extruder after printing the carousel with orange petg prusament.

This is the extruder after printing the carousel with orange petg prusament.

RE: Excessive Stringing, Surface Bumps and Burnt Filament in prints

Hi;

I assume you also went through the entire calibration process as well after the replacements,

After replacing the nozzle , did you check for any leakage , and did you replace the PTFE tube as well ? https://help.prusa3d.com/en/guide/how-to-replace-a-ptfe-tube-mk3s-mk3s-mk2-5s-mmu2s_21664

RE: Excessive Stringing, Surface Bumps and Burnt Filament in prints

I did calibrate again after making the replacements. There was leakage on top of the heater block I replaced. I did not replace the PTFE tube because it looked to be in good condition. I was going to try raising the nozzle from the bed a little bit, maybe the filament is collecting on the nozzle and block due to being too close to the print?

First dry your filament.

Cheerio,

RE: Excessive Stringing, Surface Bumps and Burnt Filament in prints

I have been drying my filament more than I do normally today and I have noticed some improvement with oozing. However, it doesn't seem to have solved the filament build up on the heaterblock. So I'm still getting deposits of charred filament in my prints.

When I last had to replace my heaterblock, heatbreak, and nozzle, I ended up getting parts off of amazon because they weren't available from prusa at the time. Maybe low-quality parts are causing a leak?

The other thing I was going to try was getting a silicone sock for the block. From looking around on the internet, it sounds like a lot of people have this issue with petg where it picks up and collects deposited plastic on the block. I saw somewhere that this may solve filament being collected on the block.

RE: Excessive Stringing, Surface Bumps and Burnt Filament in prints

Pay particular attention to the diagrams under 'Final Inspection' on:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

and nozzle, I ended up getting parts off of amazon

Be aware that some cheaper nozzles have threads that are fractionally too short to fit properly.

Cheerio

RE: Excessive Stringing, Surface Bumps and Burnt Filament in prints

Thanks, I'll make sure to have that open when installing the replacement heating element that I ordered