Kit printed beautifully, now under-extruding

My kit was delivered in Jan of 2017. I assembled it, and it printed beautifully... for a while.

Now, it won't stop under-extruding now. Approx 95mm/100mm.

I'm printing from gcode on the SD card that shipped with the printer. I'm using the roll of PLA that shipped with the kit, the dimensions are exactly 1.75mm. The pulley tension bolts are at exactly 13.0mm. The pulley is undamaged, no dust on it, and the filament has very slight marks on it from the pulley, but no grinding. The PTFE tube is undamaged.

I tried replacing with a brand new hotend. The problem still persists.

I updated the firmware. The problem still persists.

I've also tried increasing the extrusion rate. It is still having trouble.

Before the new hotend, I did occasionally see a MinTemp ERR, but not with the new one. I had moved the printer to my much colder garage.

I've also seen a jumbled mess one time on the LCD. I just powered off and on again.

Additionally, the PINDA probe wasn't doing it's job recently, and the pre-print calibration pushed down into my heated bed. This left 2 dimples in the PEI. I immediately powered the printer off, then powered it back on and tried calibrating after the nozzle cooled.

Support recommended swapping the x or y motor with the extruder motor to see if the problem persists. I REALLY don't want to do that if I can avoid it.

Support also recommended checking the voltage at the motor, and Rambo board. I'll try the board this weekend, but the motors don't look easy to access.

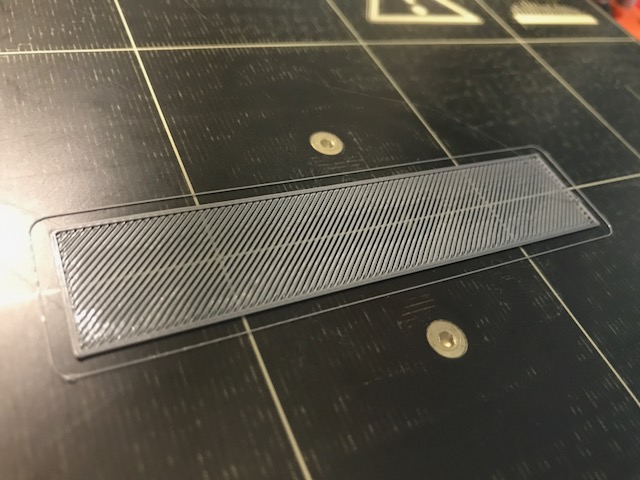

I have adjusted the z-height. I can almost overcome the difficulty that way, but the first layer is WAY too squished. I'll attach a picture. If you look at the skirt, you can observe variance in the amount of filament that is extruded. You should also be able to see that the amount of filament extruded is too little, producing a skirt of low volume.

Has anyone else experienced this? If so, how have you fixed it?

Re: Kit printed beautifully, now under-extruding

did you check the grub screws of the extruder pulleye as well ?

another possibility: check the tip of the nozzle. maybe you've squeezed the nozzle while removing cold filament with the tweezers ?

dem inscheniör is' nix zu schwör...

Re: Kit printed beautifully, now under-extruding

If the grub screw is the one that holds the pulley onto the shaft, it is tight.

This underextrusion happened with the old hotend (which I certainly could have squeezed the way you describe), but I've got a brand new hotend in there now, and it is behaving the same way.

Re: Kit printed beautifully, now under-extruding

and you are sure that you've got under-extrusion ? not a bad first layer setup, which might be misinterpreted as under extrusion ?

try to print my 75x75mm calibration surface and measure it's thickness.

dem inscheniör is' nix zu schwör...

Re: Kit printed beautifully, now under-extruding

I'll give that a shot first thing in the morning.

For what it's worth. I've tried marking 100mm on my filament, then extruding 100mm. It is pretty consistently coming out at 94-95 mm.

Thanks for the calibration gcode. I'll let you know how it turns out.

Re: Kit printed beautifully, now under-extruding

... I've tried marking 100mm on my filament, then extruding 100mm. It is pretty consistently coming out at 94-95 mm...

❓ did you ever calibrate your extrusion multiplier ?

💡 the printer/kit always comes with a slight under-extrusion. mine extruded exactly 93mm when it was uncalibrated.

that's related to the extrusion setting inside the firmware source file, which simply represents the math for the extruder pulleyes calculated physical dimensions. // Steps per unit {X,Y,Z,E}

#define DEFAULT_AXIS_STEPS_PER_UNIT {100,100,3200/8,161.3}

but because this pulleye is very small and manufacturing is liable to tolerances, you need to calibrate the extruder first.

inside the firmware 3.0.10-alpha2 was a build-in option to calibrate the extruder, but due to unexplained reasons they withdraw it for the final release.

➡ so if you got only 94,5mm instead of 100mm, why don't you just send the following g-code to your printer (using pronterface or octoprint), which sets the extrusion steps per unit to 170.69 (= 161.3 / 0.945) ?:

M92 E170.69

afterwards you need to store it permanently inside the eeprom with:

M500

note: to get the M500 doing it's job properly, you need firmware 3.0.10 (previously it was disabled at the prusa branch).

M501

M501 lets you retrieve the settings from the eeprom.

and with the M503 command, you can check if your printer really stored the value.

M503

dem inscheniör is' nix zu schwör...

Re: Kit printed beautifully, now under-extruding

oh, that's exciting. I've been away for the weekend. Hopefully I can try both your calibration square and the gcode mods tonight.

Thank you!

Re: Kit printed beautifully, now under-extruding

Thanks for the Pronterface gcode info.

I tried the calibration surface at -.625. It seemed pretty close, but a little rough. Then I dialed in the multiplier via the pronterface interface, and kicked off the calibration surface again.

Now, there are small gaps between the lines. Definitely unexpected. I thought it would have the opposite effect. I cranked the live-z down to -.625. I'll let you know how it turns out.

Re: Kit printed beautifully, now under-extruding

ok. The extrusion is nearly dead-on now.

I get the smoothest results from -.650 for live-z, though there are still some occasional tiny gaps. I'll clean the bed and try again. Could be adhesion related.

Also, the gcode models that shipped with my printer print at 210, but your calibration square prints at 215. Do you find that 215 is better for Prusa PLA?

The smooth -.650 calibration surface is .25mm thick. If I increase or decrease the live-z, the thickness increases. I was expecting a value closer to .2 for thickness.

Can you recommend any additional steps for troubleshooting?

Re: Kit printed beautifully, now under-extruding

...The smooth -.650 calibration surface is .25mm thick. If I increase or decrease the live-z, the thickness increases. I was expecting a value closer to .2 for thickness...

that's quite curious. you should find an optimum @ 0.20mm (sometimes even 0.19mm), where the sheet is a uniform film (no single strands). when you then lower the live-z adjustment value more, the sheet should get dim / rough and it's thickness should as well as increase as if you increase the live-z adjustment value.

how do you measure the thickness ? in the middle of the print, or "over the edges" (with a digital sliding calliper) ?

anyhow, as long as you are operating at the value where the thickness is the lowest, and you got no single strands, you're alright for your assembly.

about the 215°C -> that's the default temperature for the first layer @ the prusa settings for simplify3d. it's always common that you print the first layer a few degrees hotter than the rest of a model.

dem inscheniör is' nix zu schwör...

Re: Kit printed beautifully, now under-extruding

I use a set of digital calipers. They reach over the edges, so it is measuring the middle of the print.

I do notice a more dull finish when I go past -.650, though it is a .25mm thickness.

I also notice some pretty regular click/thumping during x-travel coming from the y-motor. This forum seems to indicate that mesh-bed-leveling (MBL) could be the culprit. Is is possible the MBL is causing problems with layer thickness?

I'm also noticing very fine "waves" in the strands laid down by the printer. Seems like it could also indicate mesh-bed-leveling.

Either way, I am SO much closer to fine than I was before. Your calibration surface and the extruder g-code mod are extremely helpful.

Re: Kit printed beautifully, now under-extruding

ok, as long as the 0.25mm are the lowest value you can reach and the surface is fine, it would be your optimum.

maybe your nozzle is a little bit wider than the genuine 0.40mm.

dem inscheniör is' nix zu schwör...

Re: Kit printed beautifully, now under-extruding

Can someone please explain how do I tell the printer to extrude 100 mm?

In Octoprint I tried to use the control panel and set the tool to extrude 100 mm, With the default 161.3 setting it extruded 88 mm. Then I changed it to 183.29 (161.3/0.88) it extruded more than 180 mm.

Looking at the Octoprint terminal I can see that it sent G1 E100 F300 for my 100 mm extrusion request. Is this right?

These are the steps I took:

1. Mark 150 mm on the filament.

2. Extrude 100 mm

3. Measure how much was actually extruded: 150 mm - 62 mm which were left = 88 mm

4. Calculate new value: 161.3 / 0.88 = 183.29

5. Issue the following:

M92 E183.29

M500

M501

M503

I can see that 183.29 was stored: M92 X100.00 Y100.00 Z400.00 E183.29

6. Marked 180 mm, I am not sure why but I did. Actual extrusion is more the 180 mm, the mark disapeared into the extruder.

What am I doing wrong?

Re: Kit printed beautifully, now under-extruding

After you change your extrusion parameters, send an extrusion of about 50mm first. Then measure 100 mark and send the 100mm extrusion commands and measure again.

I noticed when I changed my multiplier, the printer always did a weird extrusion the first time after I change the code. It's like it resets itself and Moves the stepper a bunch before it takes effect.

Re: Kit printed beautifully, now under-extruding

After you change your extrusion parameters, send an extrusion of about 50mm first. Then measure 100 mark and send the 100mm extrusion commands and measure again.

I noticed when I changed my multiplier, the printer always did a weird extrusion the first time after I change the code. It's like it resets itself and Moves the stepper a bunch before it takes effect.

Thanks Cory. You were absolutely right! The first extrusion is way off but the next one is on the spot.