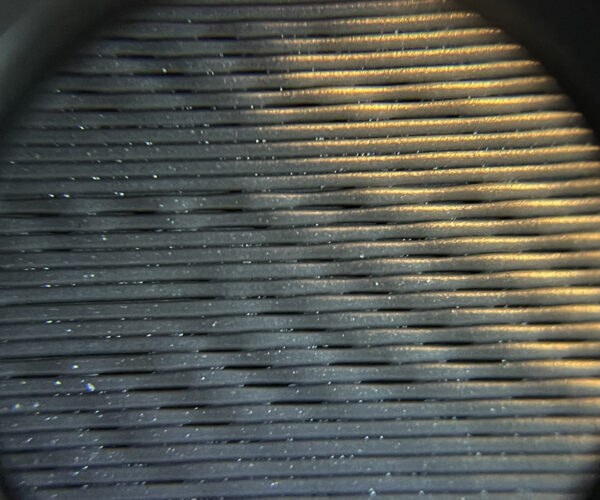

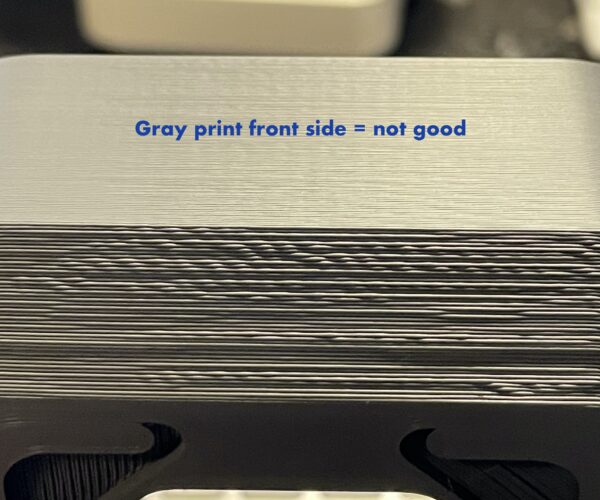

Weird extrusion artifacts on 45 happening, sometimes

Would anyone have some insight on what might be happing in these pictures?

Any help would be appreciated.

Here is a list of factors that I think are worth noting:

- Happens only on a 45, big or small

- Can be there on the print one time then I try reprinting the same g-code and then it's not there or looks different

- Printing PLA and problem shows up with different spools

- Started happing on my first Prusa Mini now it's showing up on my second one

- First Prusa Mini has been upgraded to the Bondtech Heatbreak a while back, problem only started recently, and has now been upgraded with the Bondtech extruder. Problem happed before and after. Second Mini has stock extruder but with the Bondtech Heatbreak.

- Shows up on X and Y. Also shows up on straight lines and curves

- Printers have been running 8-12 hours a day for that last several months

Best Answer by Incremental.Designs.G91:

I've done some testing over the last few months and I am 100% sure the source of the problem is the Bondtech heat-break and PID value. In addition to the problem pictured above I was also getting some jamming, not so bad that it would fully jam but enough to miss some extrusions and get stringing where I didn't get it before. Resetting the Mini to use the default PID values and removing the Bondtech suggested values from the Start G-Code, stopped the jamming and reduced the issue being seen in the pictures above. It was still there but a lot less noticeable. I've been printing with the Bondtech heat-break and default PID values for a few months without anything changing. I also removed the second fan and that had no effect on it.

I wanted to completely get rid of the weird artifacts so I have now swapped to the original Prusa heat-break the machine came with. Doing that has fully fixed the problem. So Bondtech heat-break has actually cause me more problems than the original one. I've had all 3 of my Mini's jam from the PTFE tube not being long enough or shrinking over time. Doing some adjustments and also swapping the PTFE tube out with a slightly longer Capricorn tube has fixed that.

The issue I am seeing is definitely a very specific case bases on my geometry but either way I plan to use the stock heat break from now on.

RE:

That is probably because of Mini's limited part cooling capability (because part cooling fan blows only from back side). And why that's most visible on 45deg overhang? Because here, printed layer should be cooled fast to keep it's shape and position.

The only solution I see is, that you turn object's "important" side to back (where better cooling is). You can also try to decrease print temperature by few degrees. If object has large base surface, then you can also try to decrease bed temperature.

[Mini+] [MK3S+BEAR]

RE: Weird extrusion artifacts on 45 happening, sometimes

@bogdanh I like the way you are thinking but I forgot to add that I have dual fans on both printers that have this problem. So there's an additional fan in the front. So I don't think it's not enough cooling.

But I have a theory that it's actually getting too much cooling, not the PLA but the heater block. I realize now that this happens consistently on the front and to the right side of the print. The front cooling fan blows differently until it gets to the front, going from left to right, so it cools the block when it gets to the front of the part and it can't correct itself fast enough so it extrudes less due to being too cooled. It's not an issue with the stock back fan since it's not designed to blow the air anywhere close to the heater block but the design of the front fan duct gets all around it. I also just noticed that the problem starts right on the 6th layer, which happens to be what the setting is for "Full fan speed at layer:"

I'm going to do some tests. The Bondtech heat-break with it's PID values could be playing a role in this also.

RE: Weird extrusion artifacts on 45 happening, sometimes

Many part cooling upgrades (for Mini) are not really thoroughly tested and I think they should be seen as experiments -just needed to be mentioned. Even Mini's stock part cooling solution isn't perfect, it serves me quite good and so I stick with it for now.

I don't think Bondtech heatbreak (or it's PID value) has something to do with your issue. PID value only influences hotend temperature fluctuations. Of course, if you start cooling heater block, then that will affect fluctuations -but not only at overhang on the front side of print object.

Just sharing my thoughts...

[Mini+] [MK3S+BEAR]

RE: Weird extrusion artifacts on 45 happening, sometimes

I've done some testing over the last few months and I am 100% sure the source of the problem is the Bondtech heat-break and PID value. In addition to the problem pictured above I was also getting some jamming, not so bad that it would fully jam but enough to miss some extrusions and get stringing where I didn't get it before. Resetting the Mini to use the default PID values and removing the Bondtech suggested values from the Start G-Code, stopped the jamming and reduced the issue being seen in the pictures above. It was still there but a lot less noticeable. I've been printing with the Bondtech heat-break and default PID values for a few months without anything changing. I also removed the second fan and that had no effect on it.

I wanted to completely get rid of the weird artifacts so I have now swapped to the original Prusa heat-break the machine came with. Doing that has fully fixed the problem. So Bondtech heat-break has actually cause me more problems than the original one. I've had all 3 of my Mini's jam from the PTFE tube not being long enough or shrinking over time. Doing some adjustments and also swapping the PTFE tube out with a slightly longer Capricorn tube has fixed that.

The issue I am seeing is definitely a very specific case bases on my geometry but either way I plan to use the stock heat break from now on.