Sainsmart TPU Success

I'd like to report what I consider successful printing with Sainsmart TPU. I used the Prusa Slicer default settings for Sainsmart TPU after thoroughly drying it in a dehydrator. The extruder pressure was already dialed in apparently.

Regards,

Mark

RE:

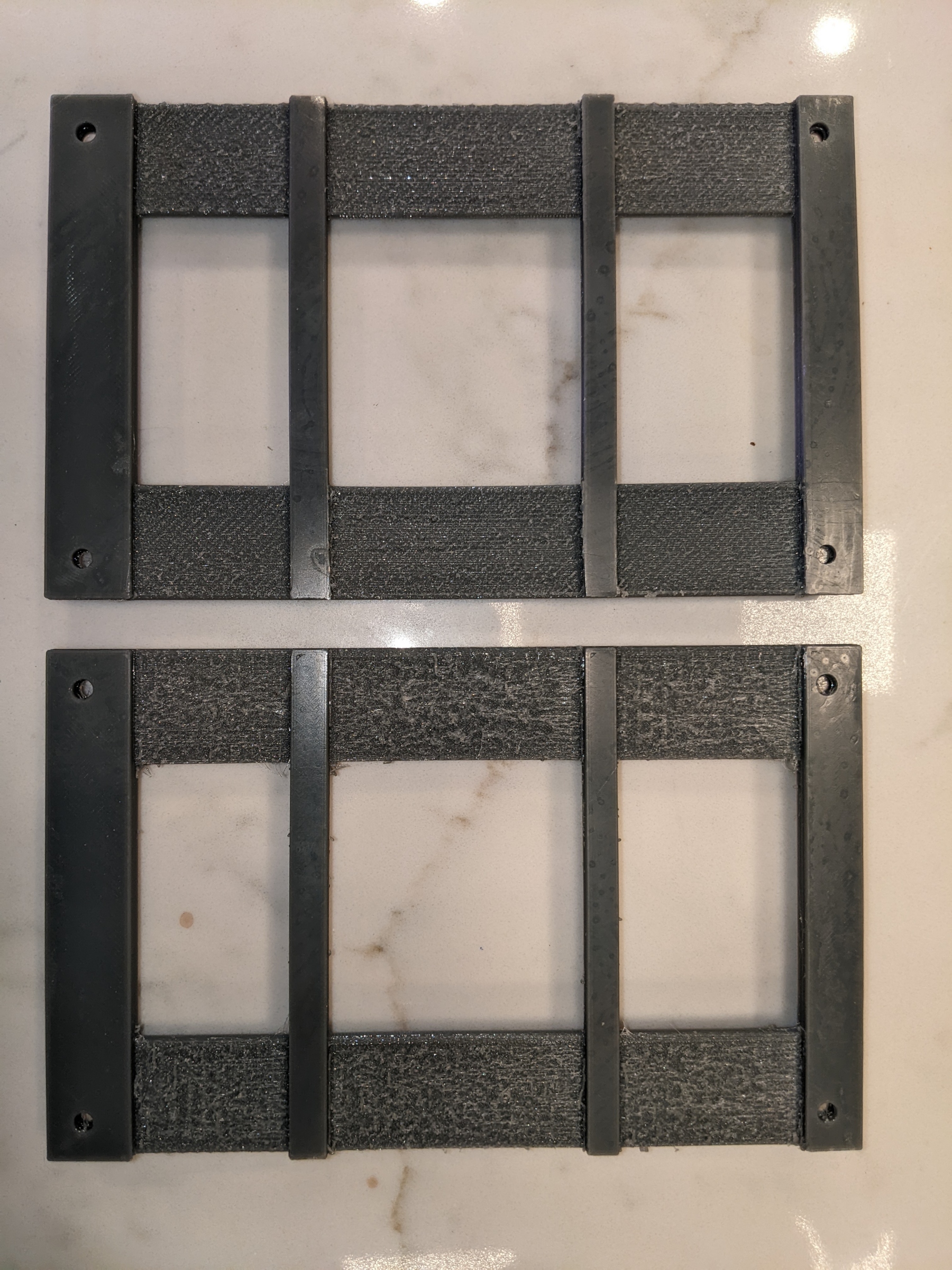

I made some more challenging parts, with supports necessary and large open areas. The following improved things.

Dry it for a couple days in a dehydrator - this improved overall quality

Print Settings | Layers and Perimeters | Check Avoid crossing perimeters - this reduces stringing as the hot end does not swing over blank area as much. Some strings wind up on the part, but are covered up by the next layers. Big strings that result in zits especially were reduced.

Print Settings | Support material | Check Generate support material - this was needed as there are large bridges on this part

Print Settings | Support material | Snug support, 0.3 mm Top contact Z distance, pattern angle 90, top interface layers 3 - this uses a crisscross pattern just below the bridge and is easier to remove with a better surface left behind.

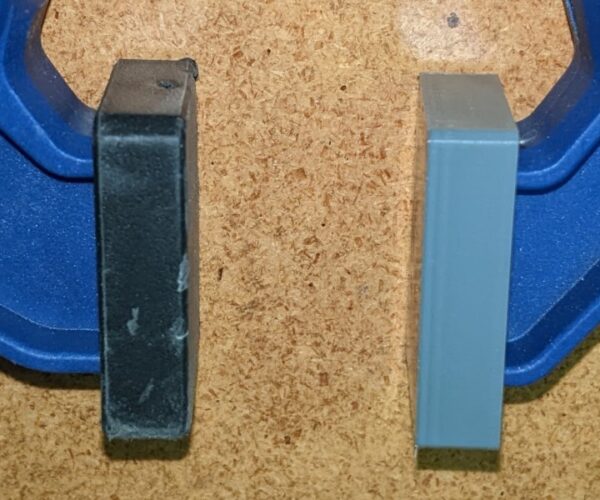

Improved versions are on the top of the following pictures:

Regards,

Mark